Kwishishini lokwenziwa kombane, umatshini wokubeka sisixhobo esisetyenziswa ngokuqhelekileyo ukunyusela ngokuchanekileyo amacandelo e-elektroniki kwi-PCB.

Ukuze kuqinisekiswe ukusebenza okuqhelekileyo komatshini wokubeka kunye nokwandisa ubomi bawo benkonzo, ukugcinwa rhoqo kubalulekile. Ezi zilandelayo zezinye iindlela

kunye nobuchule bokugcinwa komatshini wokubeka ukuqinisekisa umsebenzi wawo osebenzayo kunye nozinzile.

1. Ukucoca rhoqo: Ukucoca rhoqo kuyinyathelo eliphambili ekugcineni umatshini wokubeka

Okokuqala, cima umatshini wokubeka kwaye ukhuphe umbane. Sebenzisa iphepha lokusula i-stencil kunye ne-arhente yokucoca engagqwalisiyo ukosula ngobunono umphezulu womatshini,

ngakumbi umphezulu we-X / Y cantilever track magnetic, irula yokugawula, kunye nendawo yokucubungula i-PCB. Ngexesha elifanayo, qiniseka ukuba uhlambulule uthuli kunye ne-debris ngaphakathi

umatshini, kwaye usebenzise isicoci sevacuum ukucoca izinto ezishiyekileyo kumzila kunye neqonga lokugqogqa.

2. Amalungu okuthambisa

umatshini wokubeka luhlobo lwezixhobo ezichanekileyo. Ukuze kuqinisekiswe ukusebenza kwayo okuqhelekileyo kunye nokwandisa ubomi bayo benkonzo, ukuthambisa rhoqo ngumsebenzi obalulekileyo wokulondoloza.

Xa ukhetha i-lubricant efanelekileyo, kuyimfuneko ukuqinisekisa ukuba i-lubricant ine-anti-wear efanelekileyo kunye neempawu zokumelana nobushushu obuphezulu ukuziqhelanisa nendawo yokusebenza.

kumatshini wokubeka. Izithambisi eziqhelekileyo ziquka igrisi neoyile, kunye nezithambisi ezifanelekileyo nazo zingasetyenziswa ngokomenzi womatshini wokubeka.

iingcebiso. Ukufakwa kwe-oyile kwindlela yokuhambisa i-smeared, kwaye isilayidi se-X / Y cantilever sifakwe ioli. Emva kokuba inkqubo ye-oyile igqityiwe, izixhobo kufuneka zithwale

ngaphandle kovavanyo "lokusebenza ngokusisigxina kwe-cantilever". Ubude obucetyiswayo bumalunga nemizuzu engama-30. Kufuneka kuqatshelwe ukuba i-lubrication egqithisileyo kufuneka igwenywe, ukwenzela ukuba ingabangeli ukungaphumeleli okungadingekile.

3. Qwalasela isivamvo somqobo wokukhanya komzila

Inzwa yokuthintela ukukhanya kumkhondo womatshini wokubeka idlala indima ebalulekileyo ekumiseni okuchanekileyo kunye nokufumanisa i-PCB. Jonga rhoqo imeko yokusebenza

La malungu ukuqinisekisa ukuba acocekile kwaye alungelelaniswe ngokufanelekileyo. Ukuba iindawo ezonakeleyo okanye ezingasebenziyo zifunyenwe, zibuyisele kwangethuba.

4. Ulungelelwaniso kunye nohlengahlengiso

Ukuchaneka kunye nokuzinza komatshini wokubeka kufuna ukulungelelaniswa rhoqo (UMTHETHO, ibhodi ye-MAPING) usebenzisa i-jig ekhethekileyo. Yenza ulungelelwaniso oluqhelekileyo kunye nokulinganisa ngokuhambelana

kwimiyalelo yomenzi. Ezi ziquka ukulinganisa kwentloko ye-patch (ACT) kunye nokulinganisa kwe-X / Y axis cantilever (MAPPING). I-ACT ibuyisela ukufakwa kukonke

ukuchaneka kwentloko yokubeka, kunye ne-MAPPING ibuyisela ukuchaneka kwe-slider ye-X / Y axis (iimpawu zempembelelo ezikhulayo: kwicala elithile le-axis, i-offset jikelele). Ngendle

ukuqinisekisa ukunyaniseka kwenkqubo yokulinganisa, kufuneka iqhutywe ngabaqeqeshi ukuqinisekisa ukuchaneka kokubekwa kunye nokuzinza komatshini wokubeka.

5. Jonga unikezelo lombane kunye noqhagamshelo lombane

Jonga rhoqo ukuthembeka koxhumo lombane lomatshini wokubeka ukuze uqinisekise ukuzinza kunye nokhuseleko lwezixhobo. Khangela ukuba umbane wonikezelo lombane

ubhedu owonakalisiwe okanye oveziweyo, okhululekileyo, kwaye ukhangele ukuba uxhumano lombane luqinile. Ukuba kukho naziphi na iingxaki ezifunyenweyo, zilungise okanye uzibuyisele kwangethuba.

6. Hlaziya isoftware kunye ne-firmware

Isoftware kunye ne-firmware yomatshini wokukhetha kunye nendawo isitshixo ekusebenzeni kwayo okufanelekileyo. Hlaziya rhoqo iinguqulelo zesoftware kunye ne-firmware ukuqinisekisa ukuba imisebenzi yesoftware ye

oomatshini bagqibelele ngakumbi kwaye kukho ii-BUG ezimbalwa. Ukongeza, kuyimfuneko ukubuyisela rhoqo idatha ye-mounter (MA) kumncedisi ukukhusela ukulahleka kwedatha. Ukongeza, xa inkqubo

ayiqhelekanga, inokusombulula ukungaqhelekanga ngokubuyisela ngokukhawuleza idatha yomatshini wokubeka.

7. Abaqhubi boqeqesho

Ukongeza kumsebenzi wokugcinwa rhoqo, abaqhubi boqeqesho nabo bayinxalenye ebalulekileyo yokugcina ukusebenza okuqhelekileyo koomatshini bokubeka. Qinisekisa ukuba umqhubi uqhelekile

ngokusebenza ngokuchanekileyo komatshini wokubeka kunye nokuphathwa kweempazamo eziqhelekileyo ukunciphisa umonakalo ongeyomfuneko womatshini kunye nexesha lokuphumla.

Ngamafutshane, ukugcinwa komatshini wokubeka isitshixo sokuqinisekisa umsebenzi wawo osebenzayo kunye nozinzile. Ngokucoca rhoqo, ukuthambisa, ukulinganisa kunye nokulungelelanisa, ukujonga amandla

kunye nokunxibelelana kombane, ukuhlaziya isoftware kunye ne-firmware, kunye nabaqhubi boqeqesho, unokwandisa ubomi benkonzo yoomatshini bokubeka kunye nokuphucula ukusebenza kakuhle kwemveliso.

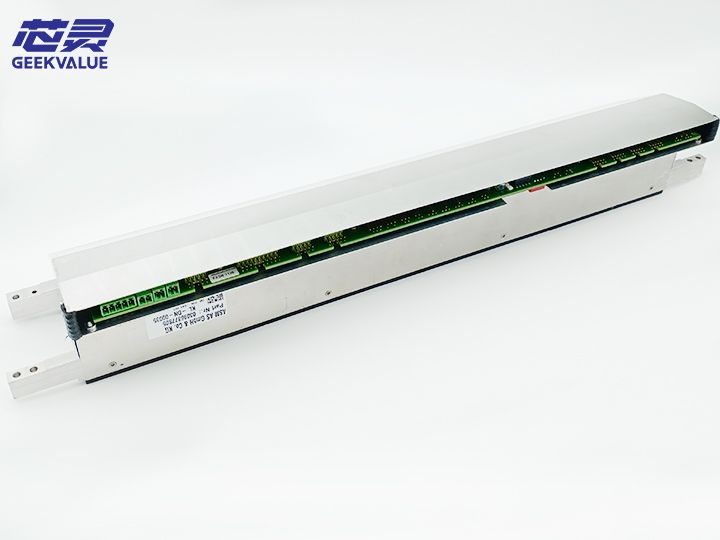

Njengomgangatho wehlabathi "ikhonkco lokubonelela + ikhonkco lobugcisa" umqhubi wenkonzo ekrelekrele koomatshini bokubeka, iXinling Industry izibophelele ekuboneleleni ngezisombululo zokumisa enye yokubekwa kwe-ASM.

oomatshini. Sineqela lobugcisa elinamava elinokubonelela abathengi ngezicwangciso zokugcinwa kwezixhobo ezenziwe ngokwezifiso kunye neenkonzo zoqeqesho. Nokuba kukukhethwa kwezixhobo,

ufakelo kunye nokugunyazisa okanye emva-kwentengiso inkxaso, siyakwazi ukubonelela abathengi ngenkxaso yobuchwephesha kunye nezisombululo. Ukuba unazo naziphi na iimfuno malunga nesondlo

kunye nokugcinwa koomatshini bokubeka, nceda uqhagamshelane nathi, siya kukukhonza ngentliziyo epheleleyo.