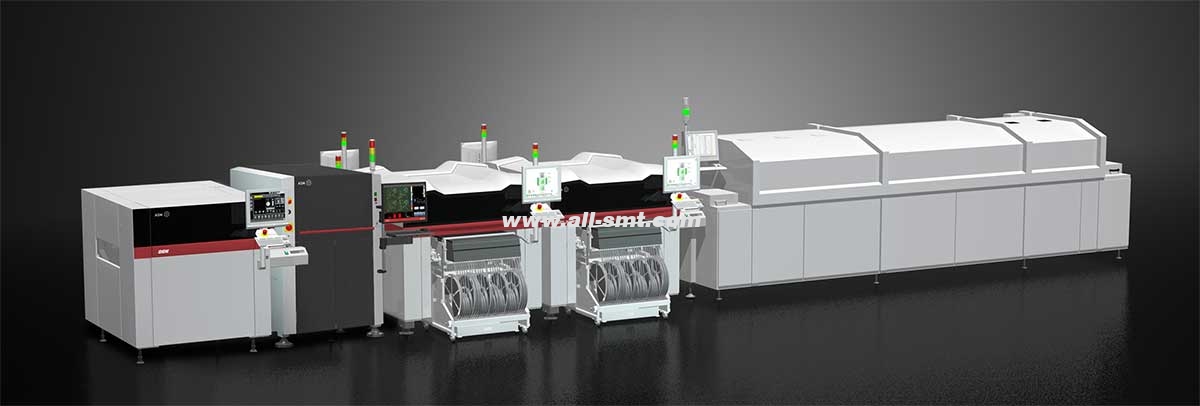

Kwishishini lokwenziwa kombane, inkqubo yendibano ye-SMT idlala indima ebalulekileyo. Ibandakanya ukubekwa ngokuthe ngqo kwamacandelo e-elektroniki kumphezulu weebhodi zesekethe eziprintiweyo (PCBs), nto leyo eyenza ukuba ibe yinxalenye ebalulekileyo yemveliso ye-elektroniki yale mihla. Kweli nqaku, siza kuphonononga kumanyathelo enkqubo yendibano ye-SMT, sikuncede ukuba uqonde isigaba ngasinye ngelixa unikezela ngolwazi olulungiselelwe i-SEO ukuphucula ukubonakala kwewebhusayithi yakho kuGoogle.

1. Yintoni iNkqubo yeNdibano ye-SMT?

Indibano ye-SMT yinkqubo yokunyuswa kwezixhobo ze-elektroniki ezifana nezixhasi, ii-capacitors, kunye neetshiphusi kumphezulu we-PCB usebenzisa itekhnoloji yokunyuswa komphezulu. Xa kuthelekiswa nobuchwephesha bomngxunya obuqhelekileyo (THT), i-SMT inikezela ngoxinaniso lwamacandelo aphezulu kunye nemijikelo emifutshane yemveliso. Isetyenziswa kakhulu kwimveliso yezixhobo ezinje ngee-smartphones, umabonakude, kunye neemoto.

2. Amanyathelo aphambili kwiNkqubo yeNdibano ye-SMT

Inkqubo yokuhlanganisa i-SMT inezigaba ezininzi, ngalinye lifuna imisebenzi echanekileyo ukuqinisekisa umgangatho kunye nokuzinza kwemveliso yokugqibela.

Ushicilelo lwe-Solder Paste

Inyathelo lokuqala kwindibano ye-SMT kukusebenzisa i-solder paste kwi-PCB. Istencil isetyenziselwa ukuprinta i-solder paste ngokulinganayo kwiipads zePCB. Ukusasazwa kwe-solder paste kubalulekile kwimpumelelo yenkqubo ye-solder elandelayo.

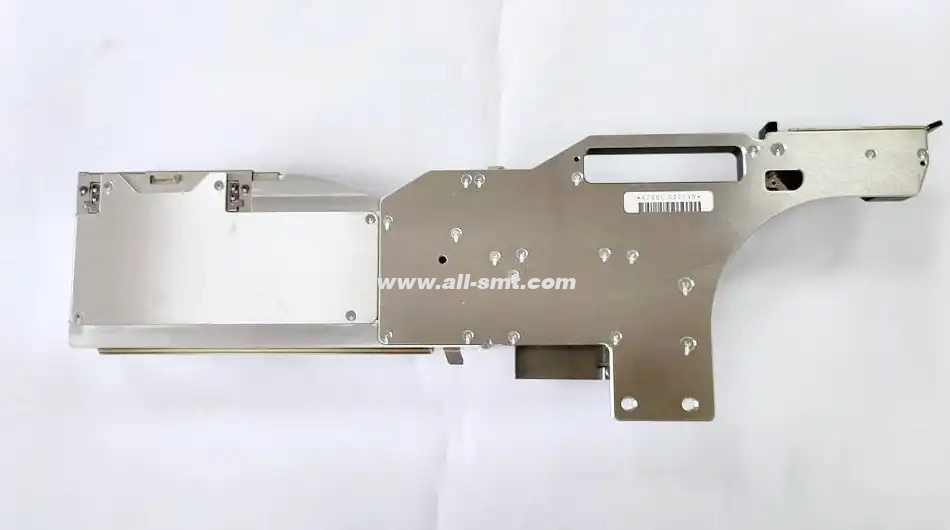

Khetha kwaye ubeke

Kweli nqanaba, umatshini wokuchola kunye nendawo ubeka amacandelo anyuswe phezulu kwi-PCB eprintwe nge-solder paste. Ukuchaneka kunye nesantya somatshini wokukhetha kunye nendawo kuchaphazela ngokuthe ngqo ukusebenza kwemveliso kunye nomgangatho wemveliso. Oomatshini banamhlanje bayakwazi ukuphatha amancinci, amacandelo achanekileyo, ukuhlangabezana neemfuno zendibano ephezulu.

I-Soldering kwakhona

Emva kokuba amacandelo abekwe kwi-PCB, ibhodi idluliswa kwi-oven ye-reflow soldering. Intlama ye-solder iyanyibilika phantsi kobushushu obuphezulu obulawulwayo, idala idibaniso elomeleleyo ye-solder phakathi kwamacandelo kunye nePCB. Ubushushu kunye nokulawula ixesha ngexesha le nkqubo zibalulekile; izicwangciso ezingafanelekanga zingakhokelela kwi-solder engalunganga okanye umonakalo kumacandelo.

Ukuhlolwa noVavanyo

Emva kokuba i-reflow soldering igqityiwe, uchungechunge lokuhlola kunye namanyathelo okuvavanya lwenziwa ukuze kuqinisekiswe umgangatho wamalungu e-solder. Iindlela zokuhlola eziqhelekileyo zibandakanya ukuhlolwa okubonakalayo, ukuhlolwa kwe-X-ray, uHlolo oluzenzekelayo lwe-Optical Inspection (AOI), kunye novavanyo olusebenzayo. Ezi ndlela zobuchule zinceda ukuchonga kunye nokulungisa nayiphi na imiba ye-solder ngaphambi kokudlulela kwinqanaba elilandelayo.

Ukucoca

Ukucoca linyathelo lokugqibela lenkqubo yendibano ye-SMT. Isusa nayiphi na intlama ye-solder eshiyekileyo okanye i-flux kwi-PCB ukuthintela ukubola kwamacandelo kunye nokuqinisekisa ubude obude kunye nokuthembeka kwemveliso.

3. Izinto eziluncedo kunye nemingeni yeNdibano ye-SMT

Izinto eziluncedo:

Ukusebenza okuphezulu kunye nokuchaneka:I-SMT ivumela ukubekwa kwecandelo loxinaniso oluphezulu, iyenze ilungele imveliso ye-elektroniki ecwengileyo nentsonkothileyo.

Ugcino-Isithuba:Ekubeni amacandelo e-SMT abekwe kumphezulu we-PCB kunokuba adlule emingxunyeni, igcina indawo exabisekileyo ebhodini.

Ukuzenzekela okuphezulu:Ukusetyenziswa koomatshini bokukhetha kunye nendawo, ii-oveni zokuphinda zifakwe kwi-solder, kunye nezinye izixhobo ezizenzekelayo zonyusa kakhulu ukusebenza kakuhle kwemveliso kunye nokungaguquguquki.

Imingeni:

IiMfuno zesiXhobo esiPhezulu:Indibano ye-SMT ifuna izixhobo ezichanekileyo, ezikhokelela kwiindleko eziphezulu zotyalo-mali lokuqala.

Umngcipheko womonakalo wecandelo:Ngethuba lokubeka kunye nokuphinda kufakwe i-soldering, amacandelo angonakaliswa ukuba amaqondo okushisa aphezulu kakhulu okanye ukuba kukho ukuphathwa ngendlela engafanelekanga.

Ulawulo lobulunga oluntsonkothileyo:Uxinaniso oluphezulu lwamacandelo lufuna i-solder echanekileyo kunye nokuhlolwa. Nakuphi na ukungaphumeleli kula manyathelo kunokuphazamisa umgangatho wemveliso.

4. IiNdlela zexesha elizayo kwiNdibano ye-SMT

Njengoko itekhnoloji iqhubeka nokuvela, indibano ye-SMT isiya ekuchanekeni okukhulu kunye nokuzenzekelayo. Nazi ezinye iindlela eziphambili zokubukela:

I-Miniaturization kunye noxinzelelo oluphezulu:Ngemfuno ekhulayo yezixhobo ezincinci kunye nezixineneyo ezifana nee-smartphones kunye nezinto ezinxitywayo, indibano ye-SMT iyavela ukuze iphathe izinto ezincinci kunye nezixineneyo.

Ukwenziwa kobuchule:Ukudityaniswa kobukrelekrele bokwenziwa (AI) kunye nokufunda komatshini kuya kuphucula ukuzenzekelayo kwendibano ye-SMT, ukuvumela ukujonga ixesha lokwenyani, ukufumanisa iimpazamo, kunye nokuphucula iinkqubo zemveliso.

Uzinzo lokusiNgqongileyo:Njengoko imimiselo yokusingqongileyo iya isiba ngqongqo, indibano ye-SMT iya kuhambela phambili kwiinkqubo ezingenalo ilothe, ezilungele ukusingqongileyo, kusetyenziswa i-solder engenalothe kunye nemathiriyeli eco-friendly.

5. Indlela yokukhetha iSixhobo esiLungileyo se-SMT kunye nabaBoneleli beNkonzo

Xa ukhetha izixhobo ze-SMT nababoneleli ngeenkonzo, le miba ilandelayo ibalulekile:

Ukuchaneka kunye nokuthembeka kweSixhobo:Oomatshini bokucofa okuphezulu kunye nendawo kunye nee-oveni zokuphinda zifakwe kwi-solder ziyimfuneko ekuqinisekiseni umgangatho wenkqubo yokuhlanganisa. Ukukhetha iimpawu ezithembekileyo kunye nezixhobo eziqinisekisiweyo kunokunciphisa umngcipheko ngexesha lemveliso.

Inkxaso yobuGcisa kunye noQeqesho:Umnikezeli wenkonzo othembekileyo akufuneki abonelele ngezixhobo kuphela kodwa ukwanikezela ngenkxaso yobuchwephesha kunye noqeqesho ukunceda amashishini aphucule impumelelo yawo yemveliso kunye nomgangatho wemveliso.

Iindleko-Ngempumelelo:Ukukhetha izixhobo ezingabizi kakhulu kunye neenkonzo ngaphandle kokuthomalalisa umgangatho kunokunceda ukunciphisa iindleko zemveliso kunye nokuphucula inzuzo.

Indibano ye-SMT lilitye lembombo letekhnoloji yokwenziwa kweemveliso ze-elektroniki zale mihla, ibonelela ngobuchule obuphezulu, ukuchaneka, kunye nesakhono sokuhlanganisana esixinana kakhulu. Ngethuba lenkqubo yokuvelisa, ukulawula ngokucophelela kwinqanaba ngalinye, ukusuka kwi-solder paste yokushicilela ukuya ekuhlolweni nasekucoceni, kubalulekile ekuqinisekiseni ukuba imveliso yokugqibela ihlangabezana nemigangatho efunekayo. Ngenkqubela phambili eqhubekayo kubuchwepheshe, indibano ye-SMT iya kuqhubeka nokuvela, ukuhlangabezana neemfuno ezikhulayo zoshishino lwe-elektroniki. Ngokuqonda iinkcukacha zenkqubo yendibano ye-SMT, unokuqinisekisa umgangatho ophezulu wemveliso kwaye uhlale ukhuphisana kwimarike.