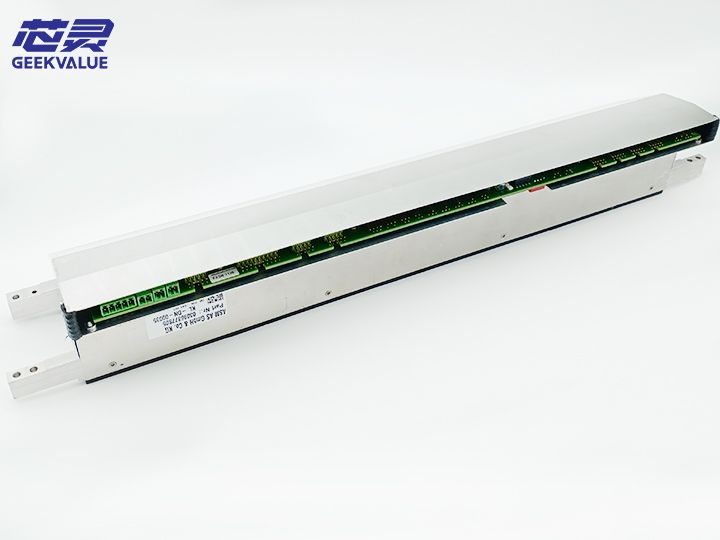

Umatshini wokubeka i-ASM iyona nto ingundoqo kunye neyona nto ibalulekileyo kwisixhobo sokuvelisa i-SMT. Ngokumalunga nexabiso, umatshini wokubeka ungowona ubiza kakhulu kumgca wonke. Ngokumalunga nomthamo wemveliso, umatshini wokubeka umisela umthamo wokuvelisa umgca, ngoko ke ngokuqhelekileyo sibiza umatshini wokubeka obizwa ngokuba ngumatshini wokubeka. Ingqondo yomgca wendibano ye-PCB, ekubeni umatshini wokubeka ubaluleke kakhulu kumgca wokuvelisa i-smt, ukugcinwa rhoqo komatshini wokubeka ngokuqinisekileyo akuyiyo into yokubaxa, ngoko kutheni umatshini wokubeka kufuneka ugcinwe kwaye kufuneka ugcinwe njani? Olu luhlu luncinci lulandelayo lweXinling Industry luya kukuxelela ngalo mxholo.

Injongo yokugcinwa komatshini wokubekwa

Kuyimfuneko ukugcina umatshini wokubeka, kunye nezinye izixhobo kufuneka zigcinwe. Ukugcinwa komatshini wokubeka ubukhulu becala kukuphucula ubomi benkonzo, ukunciphisa izinga lokungaphumeleli, ukuqinisekisa ukuzinza kunye nokusebenza kakuhle kwemveliso yokubeka, ukunciphisa ngokufanelekileyo ilahleko yezinto eziphathekayo, ukunciphisa amaxesha e-Alarm, ukuphucula ukuveliswa komatshini kunye nokuphucula umgangatho wemveliso.

Uwugcina njani umatshini wokubeka

Ukugcinwa rhoqo komatshini we-SMT Ukugcinwa rhoqo ngeveki, ukugcinwa kwenyanga, ukugcinwa kwekota

Ulondolozo lweveki:

Coca umphezulu wesixhobo; coca umphezulu wenzwa nganye, ucoce kwaye udibanise uthuli kunye nokungcola kumphezulu womatshini kunye nebhodi yesekethe, ukwenzela ukuba ugweme ukutshatyalaliswa kobushushu obungalunganga ngaphakathi kumatshini ngenxa yothuli kunye nokungcola, okubangela ukuba inxalenye yombane igqithise kwaye itshise; khangela ukuba i-screw Kukho ukukhululeka;

Ukugcinwa kwenyanga:

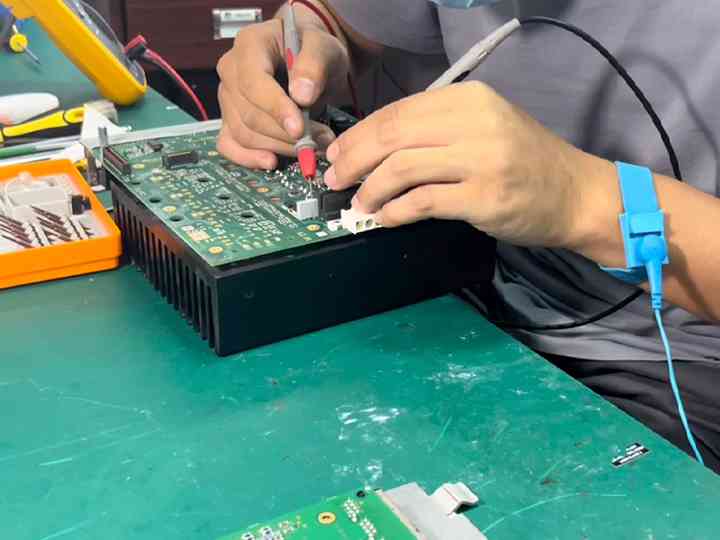

Yongeza ioli yokuthambisa kwiindawo ezihambayo zomatshini, ucoceke kwaye uthambise, (ezifana ne: screw, isikhokelo sikaloliwe, isilayidi, ibhanti lokuhambisa, ukudibanisa i-motor, njl.), Ukuba umatshini uqhuba ixesha elide, ngenxa yemeko yendalo, kuya kubakho uthuli oluncamathele kwiindawo ezihambayo Amacandelo, buyisela ioli yokuthambisa i-X kunye ne-Y axes; khangela ukuba iingcingo zokumisa zidibene kakuhle; khangela ukuba i-nozzle yokufunxa ivaliwe kwaye ungeze ioli ye-liquid ukuze ukhangele kwaye ucoce i-lens yekhamera;

Ukugcinwa kwekota:

Khangela imeko yentloko ye-patch kwisixhobo se-HCS kwaye uyigcine, kwaye ingaba umbane webhokisi lombane udibene kakuhle; Qwalasela ukuguga kunye nokukrazuka kwecandelo ngalinye lesixhobo, kwaye utshintshe kunye nokulungiswa ngokutsha (okufana noku: ukuguga kweentambo zoomatshini, ukunxitywa kweerekhi zentambo, iinjini, izikrufu zelothe) Ukukhulula izikrufu zokulungisa, njl. njl., amanye amalungu omatshini akahambi kakuhle. , izicwangciso zeparameter azilunganga, njl.).

Imizi-mveliso emininzi ayizimisi izixhobo iintsuku ezingama-365 ngonyaka, yaye amagcisa akaphumli kangako. Amagcisa efektri ikakhulu ajongana nemisebenzi elula kunye neziphene kumgca wemveliso, kwaye ayingobuchwephesha bobugcisa. Emva koko, ukugcina ukusebenza okuqhelekileyo kwesixhobo kubaluleke kakhulu. Maninzi kakhulu amathuba okulungisa umatshini. I-Guangdong Xinling Industrial Co., Ltd. ineqela lobuchwephesha lobuchwephesha. Lenze ulondolozo lonyaka kunye neenkonzo zokufuduswa kwezixhobo kwiinkampani ezininzi ezinkulu. Abavelisi be-SMT oomatshini be-chip banciphisa iindleko, baphucule ukusebenza kakuhle kwemveliso, kunye nokubonelela ngeenkonzo zobugcisa bexesha elide kwizixhobo (iinjineli zenqanaba leengcali zinokubonelela ngokulungiswa kwezixhobo, ukugcinwa, ukuguqulwa, uvavanyo lwe-CPK, ukulinganisa iMAPPING, ukuphuculwa kobuchule bokuvelisa, ukugcinwa kweemoto zebhodi, iFeida. Ukugcinwa, ukulungiswa kwentloko, uqeqesho lobugcisa kunye nezinye iinkonzo zokumisa enye).