I-Surface-Mount Technology (SMT) izondla idlala indima ebalulekileyo kwimveliso ye-elektroniki yale mihla, iqinisekisa ukuba izinto ezichanekileyo zihanjiswa ngokuchanekileyo koomatshini bokuchola kunye nendawo. I-Siemens, inkokeli kwi-automation ye-industrial automation, inikezela ngeentlobo ezahlukeneyo ze-SMT feeders, nganye eyenzelwe ukuhlangabezana neemfuno ezithile zemveliso. Nokuba umtsha kwindibano ye-SMT okanye unamava ngezixhobo ze-Siemens, esi sikhokelo siya kubonelela ngolwazi oluyimfuneko kwiimpawu, ukusebenza, kunye nokusombulula iingxaki ze-Siemens SMT feeder.

Yintoni i-SMT Feeder?

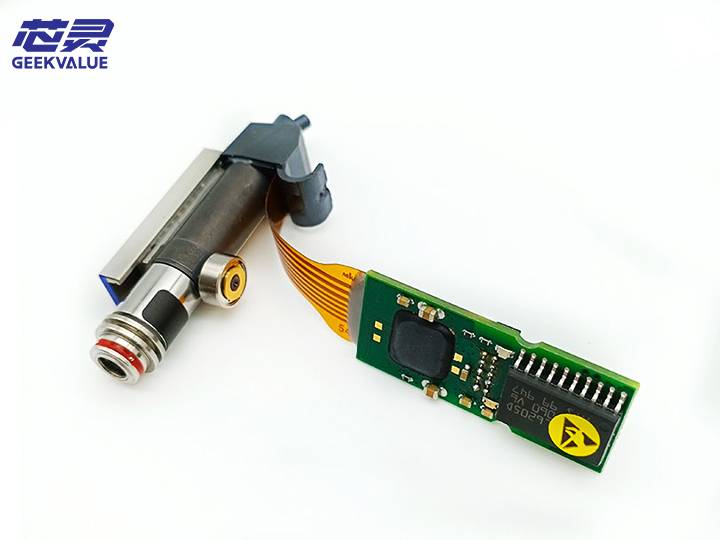

I-SMT feeder sisixhobo esibamba kwaye sinikezele ngezixhobo eziphezu komhlaba (ezifana nezixhasi, ii-capacitors, okanye ii-ICs) kumatshini wokukhetha kunye nendawo. Iqinisekisa ukuhanjiswa okuchanekileyo kunye nokuqhubekayo kwamacandelo kwintloko yokubeka umatshini. I-SMT feeder inokuba ngoomatshini okanye i-electronic, kwaye ngokuqhelekileyo ziquka ireli okanye itreyi yokubamba izinto, kunye nesixhobo esiqhutywa yimoto ukuzondla ngendlela elawulwayo nechanekileyo.

I-Siemens SMT feeders zaziwa ngokuchaneka kwazo, isantya, kunye nokusebenziseka ngokulula. Ukuguquguquka kwabo kunye nokusebenza okuphezulu kubenza babe yintsika kwiindibano ezininzi zehlabathi.

Iindidi ze-Siemens SMT Feeders

I-Siemens inikezela ngeentlobo ngeentlobo ze-SMT feeders, kuquka:

I-Standard Feeders: Ezi zintlobo eziqhelekileyo, ezifanelekileyo kuluhlu lwamacandelo. Banikezela ngokusebenza okuthembekileyo kwaye basetyenziswa kwiindawo ezahlukeneyo zokuvelisa.

I-Nozzle Feeders: Ezi zixhasi ziyilelwe amacandelo afuna ukuphathwa okukhethekileyo, njengamalungu amancinci okanye angaqhelekanga. Baqinisekisa ukuqhelaniswa okufanelekileyo kunye nokubekwa kwala macandelo.

I-High-Speed Feeders: Njengoko negama libonisa, ezi feeder ziyilelwe umatshini wokukhetha kunye nendawo enesantya esiphezulu. Ziyakwazi ukulayisha amacandelo ngesantya esikhawulezayo kwaye ngokuqhelekileyo zisetyenziswa kwiindawo zokuvelisa umthamo ophezulu.

I-Flex Feeders: Ezi zizixhobo zokutya ezibhetyebhetye kakhulu ezikwaziyo ukuphatha uluhlu olubanzi lwamacandelo anobukhulu obahlukeneyo. Ukukwazi kwabo ukuziqhelanisa neentlobo ezahlukeneyo zamacandelo kubenza balungele imigca yemveliso eguquguqukayo.

Iimpawu eziphambili ze-Siemens SMT Feeders

Indlela yokuTyelwa echanekileyo

I-Siemens SMT feeders ixhotyiswe ngeenjini eziphambili kunye neenkqubo zokulawula ezivumela ukuba zinikeze amacandelo ngokuchaneka kwe-pinpoint. Oku kunciphisa umngcipheko wokungahambi kakuhle kwaye kuqinisekisa ukuba icandelo ngalinye lithathwa kwaye libekwe kwindawo efanelekileyo.

Umthamo ophezulu

Ezi feeder ziyilelwe ukubamba iireel ezinkulu zamacandelo, ukunciphisa imfuno yokutshintsha rhoqo ngexesha lemveliso. Oku kwandisa imveliso kwaye kunciphisa ixesha lokuphumla.

UkuSeta ngokulula kunye noLondolozo

I-Siemens feeders isebenziseka lula kwaye kulula ukuyicwangcisa. Uyilo lwabo lubandakanya iimpawu ezicacileyo ezenza lula ukulayisha kunye nokukhulula amacandelo. Ukongeza, ukugcinwa kuthe ngqo, kunye namalungu atshintshekayo ngokulula kunye nemiyalelo ecacileyo yokugcina i-feeder ikwimeko ephezulu.

Inkqubo yokuJonga iSmart

I-Siemens feeders iza ixhotyiswe ngeenzwa kunye neenkqubo zokubeka iliso ezilandelela imeko ye-feeder ngexesha langempela. Oku kubonelela abaqhubi ngolwazi lwangoku malunga nokufumaneka kwecandelo, ivumela intshukumo ekhawulezayo xa iinxalenye zisebenza phantsi okanye kukho i-jam.

Ukuhambelana

I-Siemens SMT feeders ihambelana kakhulu noomatshini abahlukeneyo bokukhetha kunye nendawo, ngakumbi abo bakwii-Siemens series ezifana ne-Siplace systems. Oku kuqinisekisa indibaniselwano engenamthungo kwimigca yemveliso ekhoyo.

Indlela yokusebenzisa i-Siemens SMT Feeders

Ukusebenzisa i-Siemens SMT feeder kulula, kodwa kubalulekile ukulandela iinkqubo ezichanekileyo zokuqinisekisa ukusebenza ngokutyibilikayo kunye nokusebenza kakuhle. Nanga amanyathelo abanzi okusebenzisa i-Siemens SMT feeder:

Inyathelo loku-1: Lungisa i-Feeder

Susa ibhokisi kunye nokuHlola: Ngaphambi kokusebenzisa i-feeder, yikhuphe ngononophelo kwaye uhlole nawuphi na umonakalo obonakalayo okanye izinto ezingekhoyo. Khangela ukuba onke amalungu acocekile kwaye ayasebenza.

Faka i-Feeder: Nxiba isixhasi kwisibambi somatshini. Landela imiyalelo yomenzi wofakelo olululo, uqinisekise ukuba i-feeder incamathele ngokukhuselekileyo kwaye ilungelelanisiwe.

Inyathelo lesi-2: Layisha Amacandelo

Layisha i-Component Reel: Beka i-reel yecandelo okanye i-tray kwi-feeder. Kwizondla ezisemgangathweni, oku kubandakanya ukubeka ireel yamalungu kwindlela yokutyisa. Qinisekisa ukuba ireel ibekwe ngokuchanekileyo, njengoko ukulayisha okungafanelekanga kunokubangela imiba yokutya.

Cwangcisa Izicwangciso zeCandelo: Faka ulwazi lwecandelo elifanelekileyo kwisoftware yomatshini. Oku kubandakanya ukucacisa ubungakanani becandelo, uhlobo, kunye nezinye iiparamitha eziza kunceda umatshini ubeke amacandelo ngokuchanekileyo.

Inyathelo lesi-3: Lungisa i-Feeder

Ulungelelwaniso lwe-Feeder: Ukulinganisa kuqinisekisa ukuba i-feeder ihambisa amacandelo kumatshini wokukhetha kunye nendawo ngokuchanekileyo. I-Siemens SMT feeders idla ngokuba nomsebenzi wokulinganisa oluzenzekelayo. Landela imiyalelo ekwisikrini ukwenza ulungelelwaniso, wenze uhlengahlengiso xa lufuneka.

Inyathelo lesi-4: Qalisa iMveliso yoMveliso

Beka iliso kwiNkqubo yokuFundisa: Nje ukuba yonke into imiselwe kwaye ilinganiswe, qalisa ukuveliswa kwemveliso. Gcina iliso kwisimo se-feeder kwaye ubeke iliso kwinkqubo yokuvelisa ukuqinisekisa ukutyisa okugudileyo kunye nokubekwa kwecandelo.

Ukutshekishwa kwecandelo lokutya: Qwalasela rhoqo ukuba amacandelo ahanjiswa ngokuchanekileyo. Ukuba kuvela nayiphi na imiba (efana ne-jam yecandelo okanye ukubekwa okungalunganga), misa umatshini ngokukhawuleza kwaye ulungise ingxaki.

Inyathelo lesi-5: Guqula okanye uzalise kwakhona aMalunga

Gcwalisa kwakhona xa kuyimfuneko: Njengoko i-reel iphela, lixesha lokubuyisela okanye ukugcwalisa unikezelo lwecandelo. I-Siemens SMT feeders kaninzi iza kunye neenzwa zokulumkisa abaqhubi xa i-reel iphantsi, ukunciphisa ixesha lokunciphisa imveliso.

Coca i-Feeder: Emva kokuqhutywa kwemveliso nganye, luluvo oluhle ukucoca i-feeder ukuqinisekisa ukuthembeka kwexesha elide. Susa naluphi na uthuli okanye inkunkuma, ngakumbi kwindlela yokutya, ukuyigcina isebenza ngokufanelekileyo.

Ukusombulula ingxaki Siemens SMT Feeders

Kwanoomatshini abalungileyo banokudibana neengxaki ngamaxesha athile. Ukuba ubona nayiphi na imiba nge-Siemens SMT feeder, nantsi iingxaki eziqhelekileyo kunye nezisombululo zazo:

Component Jamming

Unobangela: Amacandelo angabambeka kwi-feeder, ebangela ijam.

Isisombululo: Jonga i-feeder ukuba ivalekile okanye iindawo ezonakeleyo. Sula naziphi na iijam kwaye ujonge ukuba i-reel yecandelo ihambelana ngokufanelekileyo.

Ukutya okungachanekanga

Isizathu: Iisetingi zecandelo ezingalunganga okanye imiba yolungelelwaniso inokubangela ukuba amacandelo ondliwe ngokungafanelekanga.

Isisombululo: Lungisa kwakhona i-feeder kwaye uqinisekise ukuba useto lwecandelo oluchanekileyo lufakwe kwisistim.

Icandelo liphela ngokukhawuleza

Unobangela: Ireli yecandelo inokuba ncinci kakhulu, okanye inkqubo yecandelo le-feeder isenokungasebenzi kakuhle.

Isisombululo: Gcwalisa kwakhona i-reel yecandelo okanye ujonge abenzi boluvo naziphi na iimpazamo.

Umondli akatyisi kwaphela

Unobangela: Umba womatshini, ulungelelwaniso, okanye umba wamandla unokuthintela umxhesho ekusebenzeni.

Isisombululo: Cima umatshini, khangela umonakalo womatshini, kwaye uqinisekise ukuba i-feeder ixhunyiwe ngokufanelekileyo kumbane.

I-Siemens SMT feeder yinxalenye ebalulekileyo yokwenziwa kombane wale mihla, ibonelela ngonikezelo lwecandelo olusebenzayo noluchanekileyo. Ukuqonda indlela yokusebenzisa kunye nokusombulula ingxaki ezi feeder kubalulekile ukugcina inkqubo yemveliso egudileyo. Ngokulandela la manyathelo achazwe kwesi sikhokelo, unokuqinisekisa ukuba i-Siemens SMT feeder yakho isebenza ngencopho yokwenziwa komsebenzi, ikunceda uphumeze ukusebenza kakuhle okuphezulu kunye nemveliso kumgca wakho wendibano ye-SMT.

Khumbula ukuba ukugcinwa rhoqo kunye nengqalelo enyamekileyo ekusetoni nasekulinganiseni kunganceda ukuthintela iingxaki ezininzi eziqhelekileyo, ukuqinisekisa ukuba imveliso yakho ihamba kakuhle kwaye ingaphazanyiswa. Ukuba iingxaki ziyaqhubeka, zive ukhululekile ukuba uqhagamshelane nencwadana yakho yemigaqo okanye uqhagamshelane nathi ukuze ufumane uncedo.