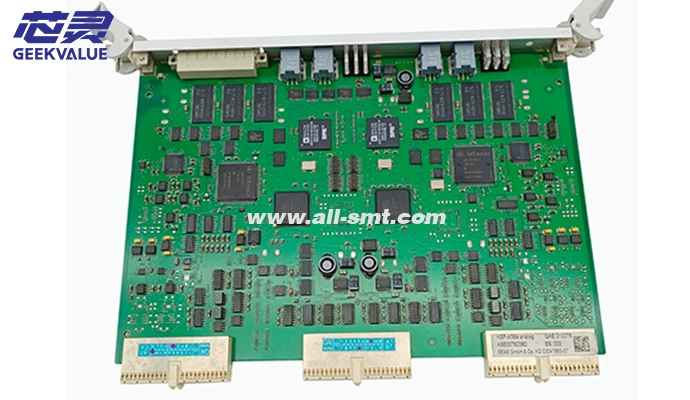

I-axis ekhohlo yebhodi yokulawula i-Siemens yokubeka umatshini iyinxalenye ebalulekileyo yomatshini wokubeka. Umsebenzi wayo kukulawula ukuhamba kwe

i-axis ekhohlo kumatshini wokubeka ukuqinisekisa ukubekwa okuchanekileyo kwamacandelo. Ukuba i-axis ekhohlo yebhodi yokulawula i-axis ayiphumelelanga, inokubangela izixhobo

ukuvala kunye nokuchaphazela ukusebenza kakuhle kwemveliso. Namhlanje ndingathanda ukwabelana nawe ngendlela yokusombulula ngokukhawuleza ukusilela konikezelo lwamandla olungaqhelekanga kwi-axis yasekhohlo ye

ibhodi yokulawula i-axis yomatshini wokubekwa we-Siemens. Eli nqaku liza kuchaza indlela yokuhlalutya kunye nokusombulula le ngxaki. Kunconywa ukuyiqokelela.

Ikhadi lokulawula i-axis ye-Geekvalue Industrial asm machine

1. Hlalutya ingxaki

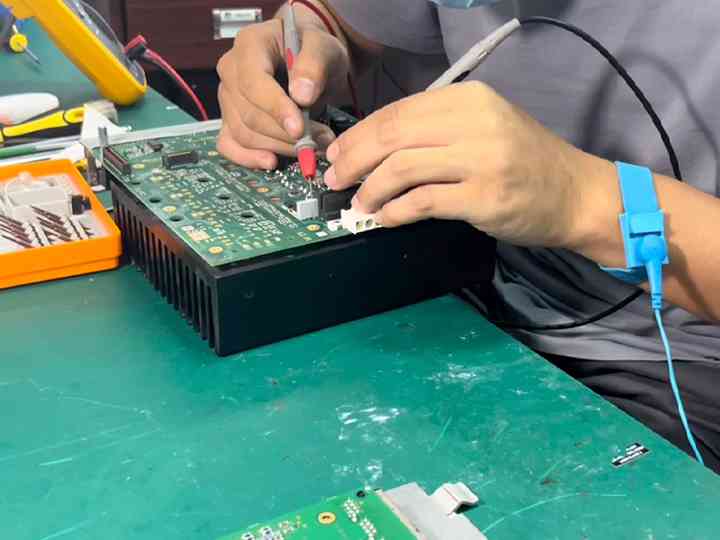

1. Khangela i-voltage yonikezelo lwamandla: Okokuqala, khangela ukuba i-voltage yonikezelo lwamandla kumatshini wokubeka we-Siemens iyinto eqhelekileyo. Sebenzisa i-multimeter ukulinganisa

i-voltage yokubonelela kwaye uqinisekise ukuba ingaphakathi koluhlu oluchaziweyo.

2. Hlola iinqununu zesekethe: Hlola iinqununu zesekethe ezinxulumene nokunikezelwa kwamandla e-axis ekhohlo kwibhodi yokulawula i-axis, njengama-capacitors, resistors, diodes, njl.

Sebenzisa i-multimeter okanye i-oscilloscope ukulinganisa ukuchasana, i-capacitance, kunye nokuqhubeka kwezi zixhobo ukuqinisekisa ukusebenza kwazo.

3. Khangela useto lwesoftware: Khangela useto lwesoftware yomatshini wokubekwa kweSiemens ukuqinisekisa ukuba iiparamitha zonikezelo lwamandla ombane ohamba ngasekhohlo zilungiswe ngokuchanekileyo.

Ukuba useto alulunganga, lunokubangela unikezelo lwamandla olungaqhelekanga.

2. Sombulula iingxaki

1. Tshintsha amacandelo angasebenziyo: Ukuba amacandelo esekethe afunyaniswa enempazamo, kufuneka atshintshwe ngexesha. Ngokweenkcukacha kunye neemfuno ze

umatshini wokubeka, khetha amacandelo afanelekileyo okutshintshwa. Nika ingqalelo kwi-welding ye-solder joints ngokuchanekileyo ukuze ugweme ukuzisa iimpazamo ezintsha

2. Khangela umgca wonikezelo lwamandla: Khangela uxhulumaniso lombane we-axis ekhohlo kumatshini wokubeka. Qinisekisa ukuba intambo yombane ayiqhawulwanga okanye ikhulule,

kwaye ujonge umonakalo okanye iisekethe ezimfutshane. Ukuba iingxaki zifunyenwe, iintambo zombane kufuneka zilungiswe okanye zitshintshwe ngexesha.

3. Ukulungiswa kwesoftware: Ukuba akukho ngxaki kumbane wombane kunye namacandelo esekethe, inokuba yimpazamo kwisethingi yesoftware ebangela

unikezelo lwamandla e-axis ekhohlo ukuba aluqhelekanga. Cwangcisa kwaye ulungise ngokusebenzisa ujongano lolawulo okanye isoftwe yomatshini wokubekwa. Jonga ukuba ngaba amandla e-axis asekhohlo

iiparamitha zonikezelo ziqwalaselwe ngokuchanekileyo, njengombane, umsinga, njl.njl. Ngokwemiyalelo yesixhobo kunye nencwadana yomsebenzisi, lungisa iiparamitha kwaye uqalise ngokutsha ifowuni.

Geekvalue Industrial asm patch machine ukugcinwa iqela

Ukuba ingxaki yonikezelo lwamandla engaqhelekanga ye-axis ekhohlo yebhodi yokulawula i-axis yomatshini wokubeka we-Siemens ayinakusombululwa ngala manyathelo angasentla,

kucetyiswa ukuba uqhagamshelane nabasebenzi bethu bobugcisa. Banokubonelela ngesikhokelo sobuchwephesha kunye nenkxaso, ukuxilonga kunye nokusombulula ukunikezelwa kwamandla okungaqhelekanga kwi-axis yasekhohlo.