Kumgca wemveliso we-SMT, abaphathi beefektri ze-SMT patch processing bahlala bexhalabile malunga nendlela yokulawula iindleko zemveliso kunye nokuphucula ukusebenza kakuhle kwemveliso.

Oku kubandakanya ingxaki yesantya sokuphosa umatshini wokubeka. Izinga eliphezulu lokuphosa umatshini wokubekwa kwe-SMT lichaphazela kakhulu ukusebenza kakuhle kwemveliso

ye-SMT. Ukuba ingaphakathi kuluhlu lwamaxabiso aqhelekileyo, yingxaki eqhelekileyo. Ukuba ubunzima obuthile bezinga lokuphosa liphezulu, ngoko kukho ingxaki. Emva koko imveliso

injineli yomgca okanye umqhubi kufuneka ayeke ngokukhawuleza umgca ukujonga isizathu sokuphosa, ukuze ungachithi inkunkuma yezinto zombane kunye nokuchaphazela umthamo wemveliso, namhlanje.

umhleli weXinling Industry uzakuxoxa nawe

1. Iingxaki ngemathiriyeli ye-elektroniki ngokwayo

Ukuba izinto ze-elektroniki ngokwazo zingahoywa ekuhlolweni kwe-PMC, kwaye izinto zombane zigeleza kumgca wemveliso ukuze zisetyenziswe, kunokukhokelela ekwandeni kokuphosa, kuba abanye

izinto ze-elektroniki zisenokucudiswa zize zibe siphene xa zithuthwa okanye ziphathwa, okanye zinokonakala xa ziphuma kumzi-mveliso. Kukho iingxaki nge-elektroniki

izixhobo ngenxa yezizathu zemveliso, ngoko oku kufuneka kusonjululwe ngolungelelwaniso kunye nomthengisi wezinto zombane, kwaye izinto ezintsha ziya kukhutshwa kwaye zigqithise ukuhlolwa.

ngaphambi kokuba zisetyenziswe kumgca wemveliso.

2. Indawo engalunganga yezinto ezixhasayo

Ezinye iilayini zemveliso zisebenza ngeeshifti ezimbini, kwaye abanye abaqhubi banokudinwa okanye bangakhathali kwaye babangele ukuba isikhululo sesondlo singalunganga. Emva koko umatshini wokubeka uya kuphosa enkulu

umthamo wezinto kunye ne-alam. Ngeli xesha, umqhubi kufuneka ajonge ngokukhawuleza kwaye atshintshe i-feeder. isikhululo semathiriyeli.

3. Isizathu sokuthatha isikhundla somatshini wokubeka

Ukubekwa komatshini wokubeka kuxhomekeke kumlomo wokufunxa kwintloko yokubeka ukuze ifunxe ngokulandelelana izinto ezihambelanayo zokubekwa. Ezinye izinto zokujula

zibangelwa yitroli okanye i-feeder kwaye izixhobo azikho kwindawo yomlomo wokufunxa okanye azikafiki kumphakamo wokufunxa. Umatshini wokubeka uya kuthabatha ngobuxoki kwaye

entabeni, kwaye kuya kubakho inani elikhulu lezitikha ezingenanto. Kule meko, kuyimfuneko ukwenza ukulungelelaniswa kwe-feeder okanye ukulungelelanisa ukuphakama kwe-nozzle yokufunxa.

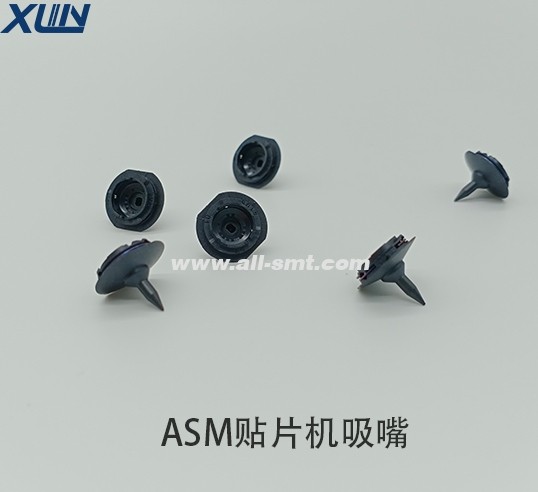

4. Iingxaki kunye nombhobho womatshini wokubeka

Abanye oomatshini bokubeka basebenza ngokufanelekileyo kwaye ngokukhawuleza ixesha elide, kwaye umbhobho wokufunxa uya kuguga, okuya kubangela ukuba izinto ziwe okanye zisilele ukufunxa, kunye nesixa esikhulu sezinto.

iya kuphoswa. Kule meko, umatshini wokubeka kufuneka ugcinwe ngexesha. Tshintsha umlomo rhoqo.

5. Ingxaki yoxinzelelo olubi lomatshini wokubeka

Umatshini wokubeka unokufunxa kwaye unyuse amacandelo, ngakumbi ukuxhomekeka kwi-vacuum yangaphakathi ukuvelisa uxinzelelo olubi lokufunxa kunye nokubekwa. Ukuba impompo yokufunxa okanye umbhobho womoya unjalo

yonakele okanye ivaliwe, ixabiso loxinzelelo lomoya liya kuba lincinci okanye linganele, ukwenzela ukuba amacandelo angenako ukuxutywa Okanye iwela ngexesha lokuhamba kwentloko yokubeka. Kule meko, i

izinto zokujula nazo ziya kwanda. Kule meko, umbhobho womoya okanye ipompo ye-vacuum kufuneka itshintshwe.

6. Impazamo yomfanekiso wokubonwa komatshini wokubeka

Umatshini wokubeka unokunyusa icandelo elikhankanyiweyo kwindawo ekhankanyiweyo yephedi, ikakhulu ngenxa yenkqubo yokuqaphela imbonakalo yomatshini wokubeka. Inkqubo yokuchonga okubonakalayo

kumatshini wokubekwa uyaqaphela inani lezinto eziphathekayo, ubungakanani, kunye nobukhulu becandelo, kwaye emva koko udlula kumatshini wokubeka. Ialgorithm yomatshini, nyusa icandelo kwi

PCB pad echaziweyo, ukuba kukho uthuli okanye uthuli embonweni, okanye ukuba yonakele, kuya kubakho impazamo yokuqaphela, nto leyo eya kukhokelela kwimpazamo ekuthatheni izinto, okukhokelela ekwandeni kokuphosa.

yemathiriyeli. Kule meko, umbono kufuneka utshintshwe inkqubo yokuqaphela.

Ukushwankathela, kukho izizathu ezininzi eziqhelekileyo zokuphoswa koomatshini bokubeka. Ukuba kukho ukwanda kokuphosa kwifektri yakho, kufuneka uhlolisise ngokufanelekileyo ukuze ufumane unobangela wengcambu. Wena

Ungaqala ubuze abasebenzi abakwisiza, ngenkcazo, emva koko ufumane ingxaki ngokusekwe kuqwalaselo kunye nohlalutyo, ukuze ukwazi ukufumana ingxaki ngempumelelo, ukuyisombulula, kwaye

ukuphucula ukusebenza kwemveliso.