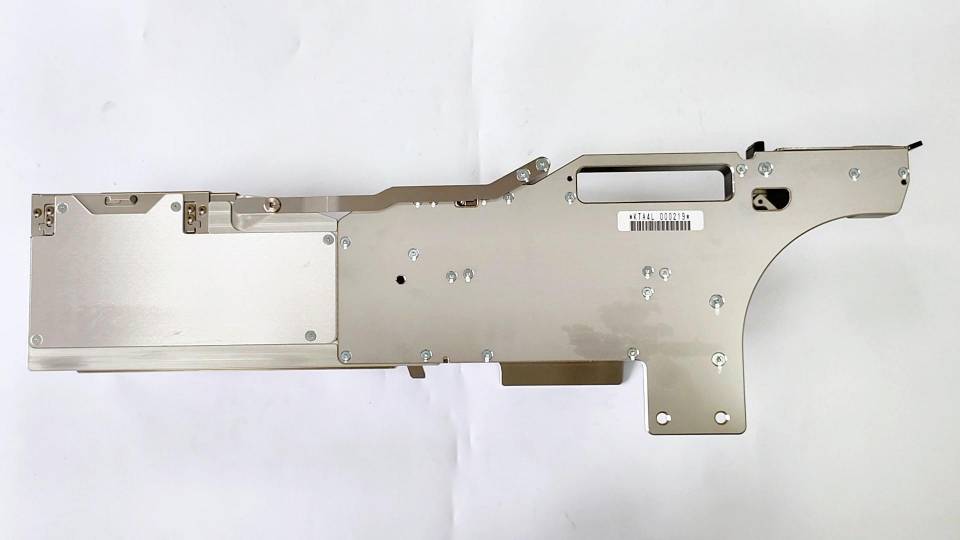

Imisebenzi ephambili kunye neziphumo zomatshini we-Fuji SMT 8MM feeder ziquka:

Ukuhanjiswa kwecandelo kunye nokubeka indawo: I-8MM feeder yinxalenye ebalulekileyo yomatshini we-SMT, osetyenziswa kakhulu ukuthatha amacandelo kwi-tray yezinto kwaye uwabeke ngokuchanekileyo kwibhodi ye-PCB. Umgaqo wayo wokusebenza kukuqhuba isilayidi ukuba sihambe ngesantya esithile ngemoto, ibambe okanye ifunxe izinto, uze uzibeke kwibhodi yePCB ngokwendawo esetwe kuyo.

Ukuphucula ukusebenza kakuhle kwemveliso kunye nokuchaneka: Ukulinganisa kwe-feeder kuchaphazela ngokuthe ngqo ukuchaneka kunye nokusebenza kakuhle kwemveliso yomatshini we-SMT. Ukulinganisa rhoqo kwe-feeder kunokuqinisekisa ukuba amacandelo athatyathwa kwaye afakwe kwindawo echanekileyo, ukunciphisa ixesha lokunciphisa kunye nesantya sephutha kumatshini we-SMT, kwaye ngaloo ndlela kuphuculwe ukusebenza kakuhle kwemveliso. Ukunciphisa ukungaphumeleli kunye nokwandisa ubomi besixhobo: Ukulinganisa rhoqo kwi-feeder kunokunciphisa ukunxiba koomatshini, ukufumanisa kunye nokulungisa iingxaki ngexesha, ukuthintela umonakalo wesixhobo, kwaye ngaloo ndlela ukwandisa ubomi benkonzo yezixhobo. Ukunciphisa iindleko zemveliso: Ngokulungelelaniswa kwe-feeder, izinga le-scrap kunye namaxesha okusebenza kwakhona anokuncitshiswa, ukuqinisekisa ukuba icandelo ngalinye linokufakwa ngokufanelekileyo, ukunciphisa inkunkuma yezinto eziphathekayo, kwaye ngaloo ndlela kuncitshiswe iindleko zemveliso. Ugcino kunye neendlela zokulinganisa

Ukuze ugcine ukusebenza okuqhelekileyo kwe-feeder, ukugcinwa rhoqo kunye nokulinganisa kuyafuneka:

Ukucoca rhoqo: Coca i-feeder ukukhusela uthuli ekuqokeleleni kwisilayidi, ukulungiswa kwe-feeder kunye nezinye iindawo, ezichaphazela ukuchaneka.

Ukufakwa amafutha rhoqo: Thambisa iindawo eziphambili ze-feeder ukunqanda ukukhuhlana okwandisiweyo ekubangeleni ukuchaneka okuhlayo kunye nokwanda kwengxolo.

Rhoqo buyisela isihluzo somthombo womoya: Qinisekisa ukuba umthombo womoya awuqulathanga ukufuma kunye nokungcola ukuqinisekisa isiphumo se-adsorption somlomo.

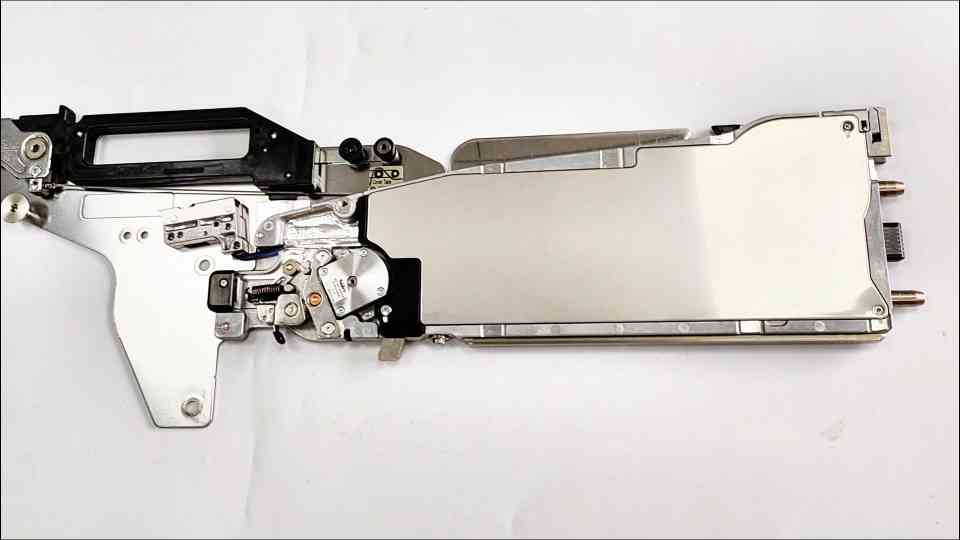

Ukuhlolwa rhoqo kwamalungu: Khangela ukuba iindawo ze-feeder zonakele okanye zikhululekile ukuqinisekisa ukusebenza kwazo okuqhelekileyo.

Ulungelelwaniso lwesixokelelwano esibonakalayo: Lungisa indawo kunye nobude bogxininiso ngekhamera, misela indawo yereferensi yendawo yesondlo, kwaye wenze ulungelelwaniso oluzenzekelayo.

Ukulinganisa komatshini: Khangela ukuba ngaba iinxalenye zomatshini we-feeder ziqhelekileyo, sebenzisa izixhobo eziqhelekileyo zokubhekisela ukulinganisa indawo kunye ne-angle, kwaye ulungelelanise iibholithi zokulungisa.

Ulungelelwaniso lweSoftware: Faka kwaye usebenzise isoftware yolungelelwaniso oluhambelanayo, faka iiparamitha zolungelelwaniso oluhambelanayo, yenza ulungelelwaniso oluzenzekelayo kwaye uqinisekise iziphumo.

Ngala manyathelo okugcina kunye nokulinganisa, ukusebenza okuqhelekileyo kunye nomsebenzi osebenzayo we-8MM feeder unokuqinisekiswa.