Sony SMT kamera sistemi, parça tanımlama ve düzeltme işlevleri başta olmak üzere SMT sürecinde hayati bir rol oynar.

Kamera sisteminin çalışma prensibi ve işlevi

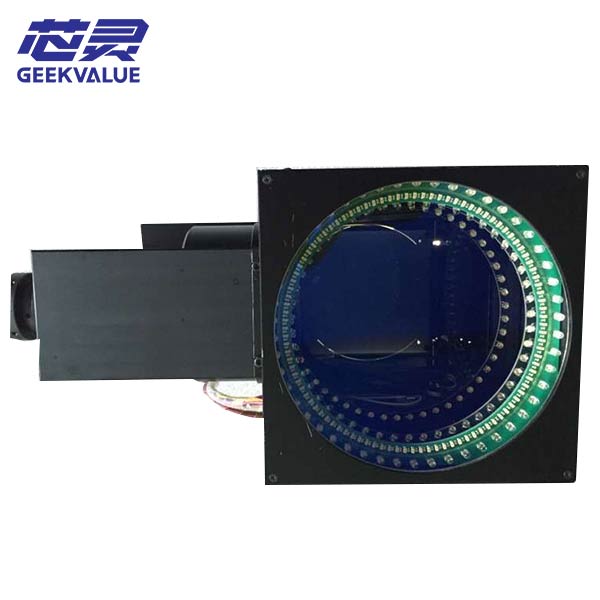

Sony SMT kamera sistemi, yüksek çözünürlüklü kameralar ve görüntü işleme teknolojisi aracılığıyla elektronik bileşenleri doğru bir şekilde tanımlar ve konumlandırır. Özellikle, kamera sisteminin iş akışı aşağıdaki adımları içerir:

Emiş talaşı: Besleyiciden vakum adsorpsiyonu yoluyla bileşenlerin emilmesi.

Düzeltme: Parça kamerası kullanılarak bileşenlerin merkez ofseti ve sapması belirlenip, XY ekseni ve RN ekseni üzerinden düzeltilmesi.

Üfleme çipleri: Elektromanyetik joystick ile çalıştırılan nozul, bileşenleri PCB kartına yerleştirir.

Farklı SMT makinesi modellerinin kamera sistemlerindeki farklılıklar

Sony SMT makinelerinin farklı modelleri kamera sistemlerinde de farklılık gösterir. Örneğin, SI-G200 modeli, 40μ, 3σ1'e kadar yerleştirme doğruluğu ile son derece küçükten büyük düzensiz şekillere kadar değişen elektronik bileşenleri işleyebilen iki yüksek hızlı planet SMT konnektörü ile donatılmıştır. SI-F130 modeli, 0402'den 12mm IC'ye kadar değişen bileşenleri 50μ'ye kadar yerleştirme doğruluğu ile işleyebilen yüksek hassasiyetli bir yerleştirme kafasına sahiptir.

Kamera sisteminin teknik parametreleri ve bakımı

Sony yerleştirme makinesinin kamera sistemi teknik parametreler açısından iyi performans gösteriyor. Örneğin, SI-G200'ün yerleştirme hızı 45.000cph'ye ulaşabilir ve yerleştirme doğruluğu 45μ, 3σ1'dir. Günlük bakımda, lensin düzenli olarak temizlenmesi ve görüntü işleme sisteminin normal çalışmasını sağlamak için kontrol edilmesi gerekir. Ayrıca, düzenli kalibrasyon ve yağlama da kamera sisteminin yüksek hassasiyetini korumak için önemli önlemlerdir.

Özetle, Sony yerleştirme makinesinin kamera sistemi, yüksek hassasiyetli görüntü işleme ve düzeltme fonksiyonlarıyla yerleştirme sürecinin doğruluğunu ve verimliliğini garanti altına almakta olup, modern elektronik üretiminin vazgeçilmez bir anahtar ekipmanıdır.