KIMMON is a leading fiber laser manufacturer in China, focusing on the research and development and production of industrial-grade fiber lasers. Its products are known for their high stability, high cost-effectiveness and localized services, and are widely used in cutting, welding, marking and cleaning. The following is a detailed introduction to its core product lines and technical features:

1. Core product lines and features

(1) Continuous fiber laser (CW)

Power range: 500 W ~ 20 kW

Application: metal cutting (carbon steel, stainless steel, aluminum alloy), welding (deep fusion welding, tailored welding).

Özellikler:

Beam quality (BPP): <2.5 mm·mrad (low-order mode), suitable for high-precision processing.

Electro-optical efficiency: >35%, energy-saving and environmentally friendly.

Stability: 24/7 continuous operation, life span >100,000 hours.

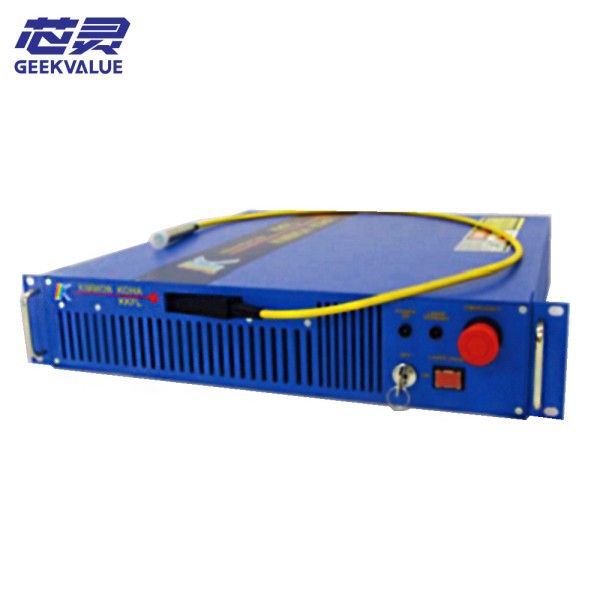

(2) Pulsed fiber laser (MOPA/Q switch)

Power range: 20 W ~ 500 W

Application: precision marking (metal/plastic/ceramic), brittle material cutting (glass, sapphire).

Özellikler:

Adjustable pulse width: 2~500 ns (MOPA technology), adaptable to different material requirements.

Repetition frequency: 1 kHz ~ 2 MHz, support high-speed processing.

(3) High-power fiber laser (multi-mode)

Power range: 1 kW ~ 30 kW

Application: thick plate cutting (50 mm+), heavy welding (ships, pipelines).

Özellikler:

Anti-reflection design: can process highly reflective materials such as copper and aluminum.

Modular structure: supports multi-laser linkage (such as 3D cutting head).

2. Technical advantages

(1) Independent core technology

Domestic fiber devices: reduce dependence on imported components and control costs.

Intelligent temperature control system: real-time heat dissipation adjustment to ensure long-term power stability.

(2) High reliability design

All-fiber structure: no optical lens, shockproof and dustproof, suitable for harsh industrial environments.

IP65 protection level: some models support high protection and are suitable for dusty/humid scenes.

(3) Flexible customization

Optional wavelengths: 1064 nm (standard), 532 nm (green light), 355 nm (ultraviolet).

Interface compatibility: supports EtherCAT, RS485, and is compatible with mainstream CNC systems (such as Berchu and Beckhoff).

3. Tipik uygulama senaryoları

Industry Application cases Recommended models

Metal processing Sheet metal cutting (stainless steel, carbon steel) KM-CW6000 (6 kW)

Automobile manufacturing Battery tray welding, body-in-white cutting KM-CW12000 (12 kW)

Electronics industry PCB marking, FPC precision cutting KM-P50 (50 W MOPA)

New energy Solar bracket welding, lithium battery pole piece cutting KM-CW4000 (4 kW)

Aerospace Titanium alloy structural parts repair KM-CW8000 (8 kW)

4. Comparison of competing products (KIMMON vs. international brands)

Features KIMMON IPG (international) Ruike (domestic)

Price Low (domestic advantage) High Medium

Power range 500 W~30 kW 50 W~100 kW 1 kW~40 kW

Service response Localized fast support Global network (longer cycle) Domestic coverage

Applicable scenarios Mid-to-high-end industrial market Ultra-high power field General industrial market

5. Temel avantajların özeti

Cost-effective - Domestic supply chain reduces customer costs.

Stable and reliable - All-fiber design, adaptable to harsh industrial environments.

Flexible customization - Power, wavelength, and interface can be adjusted as needed.

Local service - Quick response, providing on-site technical support.

Applicable customer groups:

Small and medium-sized sheet metal processing plants

Automobile/new energy equipment manufacturers

Electronic precision processing companies

6. Product selection guide

Demand Recommended series Typical models

Thin plate cutting (<10 mm) Medium power continuous laser KM-CW2000 (2 kW)

Thick plate cutting/welding High power multimode laser KM-CW15000 (15 kW)

Precision marking/engraving MOPA pulse laser KM-P30 (30 W)

High-reflection material processing High-reflection special laser KM-CW6000-AR (6 kW)