Under lappreparation kan vissa tillbehör vara felaktiga. Vi vet alla att reparationen av varje felfenomen kräver mycket tid att undersöka och testa. Idag har vi sorterat ut några vanliga fel på TX-seriens monteringskameror. Det är bekvämt för alla att snabbt eliminera problemet när de stöter på ett problem i framtiden.

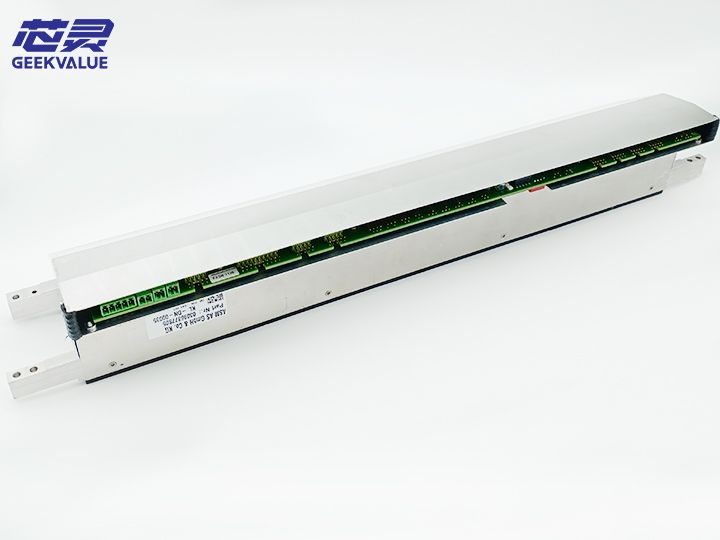

Vanliga felpunkter för TX-seriens monteringskameror

1. Test av LED-belysning misslyckades

2. Kan inte detektera videosensorn automatiskt

3. Kameran känns inte igen

4. Dataöverföringen mellan kameran och PC vision-gränssnittskortet avbryts.

Ovanstående är de vanliga felpunkterna för monteringskameror. Jag tror att alla har en viss förståelse för de vanliga felpunkterna hos mounter TX-seriekameror. Med vetenskapens och teknikens framsteg har priset på vissa elektroniska komponenter stigit många gånger. Att skydda relaterade kretskort är att minska kostnaderna och skapa vinster för företag.

Därefter kommer vi att sammanfatta underhållsförmågan hos monteringskameran.

Först: Upptäck kamerans strömförsörjning och jord (se om det finns en kortslutning till marken), och studera orsaken.

För det andra: kontrollera om komponenter som dioder är normala

För det tredje: Kontrollera om kondensatorn är kortsluten eller öppen.

För det fjärde: Kontrollera parametrarna för de integrerade kretsarna relaterade till kretskortet, såväl som relaterade komponenter som motstånd.

Ovanstående handlar om driftsstegen för kameraunderhåll. Under underhållsprocessen bör vi vara särskilt uppmärksamma för att säkerställa att strömförsörjningen är normal under mätningen och att inga sekundära skador kan uppstå.

Kontakta oss om du har problem med monteringskamerafel. Guangdong Xinling Industrial Co., Ltd. har ett professionellt tekniskt team för att tillhandahålla one-stop-underhållslösningar för montörer. Det finns mycket praktisk erfarenhet, vi är engagerade i att minska kostnaderna, förbättra produktionseffektiviteten och tillhandahålla långsiktiga tekniska tjänster för utrustning för de flesta SMT-tillverkningsföretag som använder placeringsmaskiner (ingenjörsteam på expertnivå kan tillhandahålla reparation av utrustning, underhåll, modifiering, CPK-testning, MAPPNING-kalibrering, förbättring av produktionseffektiviteten, underhåll av bräda Ka-motorer, underhåll av matare, underhåll av patchhuvud, teknisk utbildning och andra tjänster).

Kontakta oss om du har problem med monteringskamerafel. Guangdong Xinling Industrial Co., Ltd. har ett professionellt tekniskt team för att tillhandahålla one-stop-underhållslösningar för montörer. Det finns mycket praktisk erfarenhet, vi är engagerade i att minska kostnaderna, förbättra produktionseffektiviteten och tillhandahålla långsiktiga tekniska tjänster för utrustning för de flesta SMT-tillverkningsföretag som använder placeringsmaskiner (ingenjörsteam på expertnivå kan tillhandahålla reparation av utrustning, underhåll, modifiering, CPK-testning, MAPPNING-kalibrering, förbättring av produktionseffektiviteten, underhåll av bräda Ka-motorer, underhåll av matare, underhåll av patchhuvud, teknisk utbildning och andra tjänster).