SMT Placement machine play a vital role in the electronics manufacturing industry, and DP motor software disable failures may cause production line shutdowns, delays in production

schedules, and seriously affect work efficiency and production capacity. This article will delve into this problem and provide relevant practitioners with solutions to help

them quickly solve such problems and ensure the normal operation of the production line.

The DP motor software disable fault of the placement machine means that the DP motor software is accidentally disabled during the operation of the placement machine,

causing the machine to fail to work normally. Such failures can shut down production lines, resulting in reduced productivity and limited capacity. At the same time, delays

in production schedules will also bring economic losses and reputational risks to the company.

Failure Cause Analysis

1. Software setting error: The DP motor software disable failure of the placement machine is often caused by software setting error. Operators may make operating errors

during software settings and disable the software by mistake.

2. Power failure: The DP motor software disable failure of the placement machine may also be caused by power failure. Problems such as unstable power supply, high or

low voltage can cause the motor software to disable.

Solution

1. Check the software settings: First, the operator should carefully check the software settings of the placement machine to ensure that the settings are correct. The correct

setup procedure can be confirmed by reviewing the operation manual or consulting technical support personnel.

2. Check the stability of the power supply: the operator should check whether the power supply used by the placement machine is stable. The stability of the power supply

can be confirmed by using a voltmeter or consulting an electrical engineer. If you find that there is a problem with the power supply, you need to repair or replace the power supply device in time.

3. Restoring the software settings: If it is determined that the software settings are wrong and cause the DP motor software to disable the fault, the operator can try to restore

the default settings or reset the software parameters. Before operation, be sure to back up the software settings of the placement machine to avoid losing important data.

4. Seek technical support: If the above methods cannot solve the problem, the operator should seek professional technical support in time. As a leading maintenance service

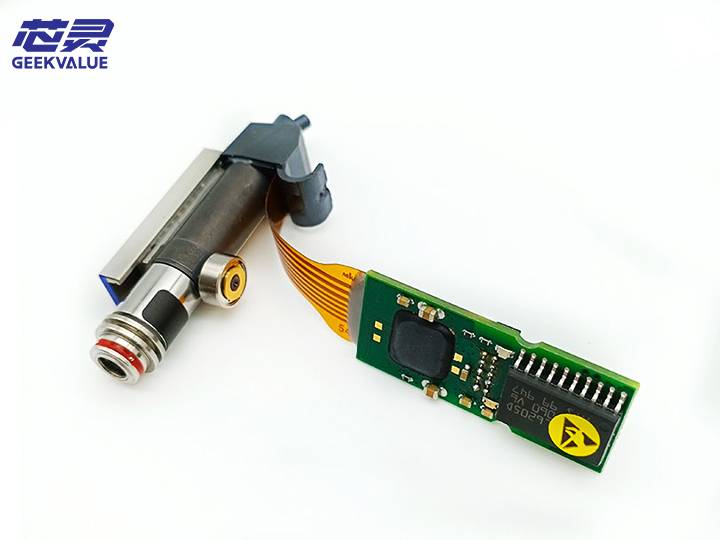

provider for placement machines in the industry, Geekvalue Industry has an experienced technical team that can quickly identify and solve various problems such as software disable

failures of the placement machine DP motor.

DP motor software disable failure of placement machine may seriously affect the production line, but by carefully checking software settings and power stability, restoring software

settings or seeking technical support, we can quickly solve this problem and ensure the normal operation of the production line. For those engaged in related work, mastering these

solutions will help improve work efficiency and reduce economic losses caused by production line failures.