In today’s fast-paced world of electronics manufacturing, staying ahead of the competition requires more than just maintaining your production line—it demands smart, flexible solutions that optimize efficiency and reduce costs. For companies that rely on surface-mount technology (SMT) machines, controlling expenses is often a top priority, and innovation plays a critical role in achieving these goals.

At Geekvalue, we have seen firsthand how forward-thinking companies are cutting costs and boosting efficiency through strategic approaches to equipment management, repair services, and parts procurement. Here’s how we’re helping them succeed.

1. Transitioning to Equipment Leasing Models

Many SMT manufacturers have shifted from purchasing equipment outright to leasing models. This strategy not only frees up capital for other investments but also allows companies to upgrade their equipment more frequently, ensuring they have the latest technology without the significant upfront costs. By leasing pick-and-place machines, manufacturers can focus on maintaining high production rates without being weighed down by the financial burden of ownership.

2. Optimizing Production Lines

Efficiency is key to staying competitive in electronics manufacturing. Our experts help businesses optimize their production lines by analyzing their current equipment and processes. By identifying bottlenecks and inefficiencies, we recommend targeted improvements that minimize downtime and maximize throughput. This results in higher output with fewer resources, helping companies reduce their operational costs while maintaining high-quality standards.

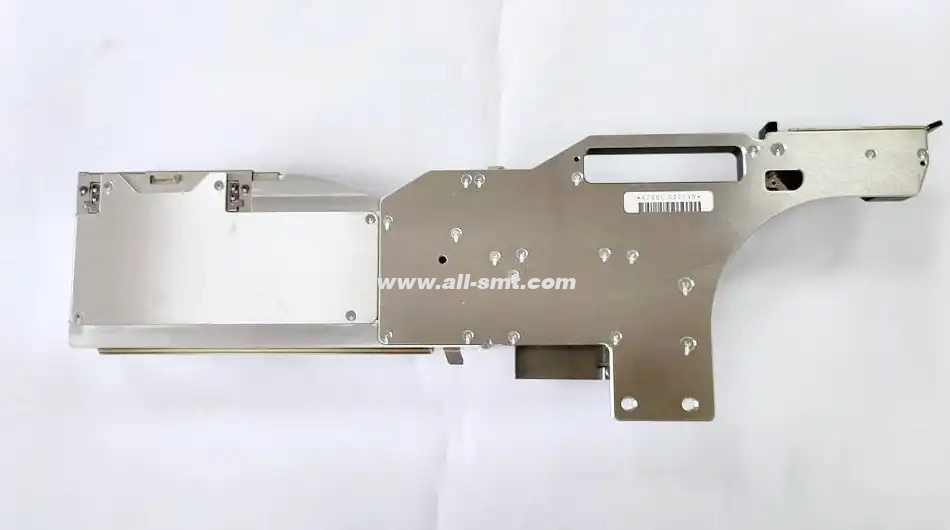

3. Strategic Parts Procurement and Repair Services

Purchasing parts and maintaining SMT machines can be a significant cost burden for manufacturers. To alleviate this, we provide cost-effective parts purchasing plans that allow companies to maintain their machines without breaking the bank. Additionally, our repair and maintenance services ensure that production stays on track, with minimal interruptions caused by equipment breakdowns. By focusing on preventive maintenance, we help companies avoid costly repairs and ensure their machines operate at peak performance.

4. Comprehensive Maintenance and Support Services

Our clients benefit from our comprehensive maintenance and support services, which include regular checkups, fast repairs, and long-term care plans for their SMT machines. We ensure that downtime is kept to a minimum and that equipment operates smoothly and efficiently. This proactive approach to maintenance keeps costs down and maximizes the lifespan of the machines.

Innovation Leads to Success

The combination of leasing options, optimized production lines, and strategic parts and repair plans has allowed companies to save millions in operational costs. By embracing these innovative solutions, SMT manufacturers can reduce their cost base while improving production efficiency, giving them a competitive edge in the market.

Partner with Us for Smarter SMT Solutions

We’re committed to helping SMT manufacturers find smarter, more cost-effective ways to manage their operations. Whether you're looking to optimize your production line, cut down on parts costs, or explore equipment leasing options, we’re here to help.

Contact us today to learn more about how we can support your business with our innovative solutions.