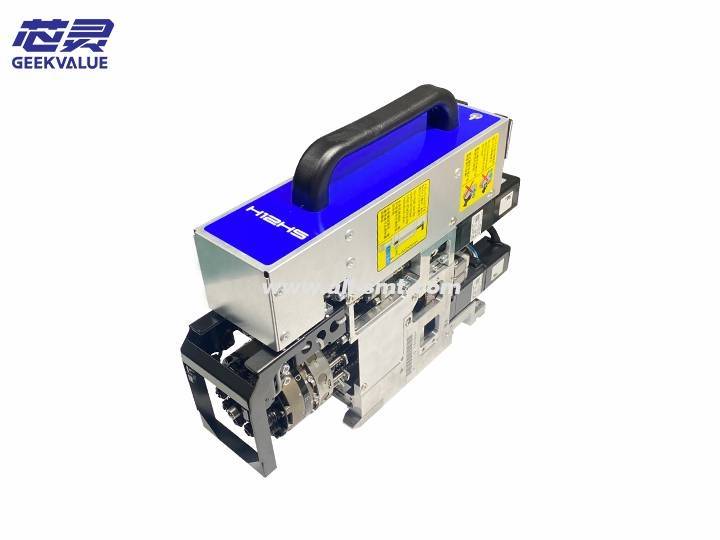

Fuji SMT pick and place machine is an efficient automation equipment widely used in the electronics manufacturing industry, but fuji mounter often encounters some faults during use. This article will focus on the common faults and solutions of Fuji smt mounter to help users better maintain and repair Fuji chip mounter equipment.

First, SMT machine cannot load materials

Fault performance: Fuji SMT mounter can not take material normally.

Analysis of possible causes:

conveying parts are not running or blocked;

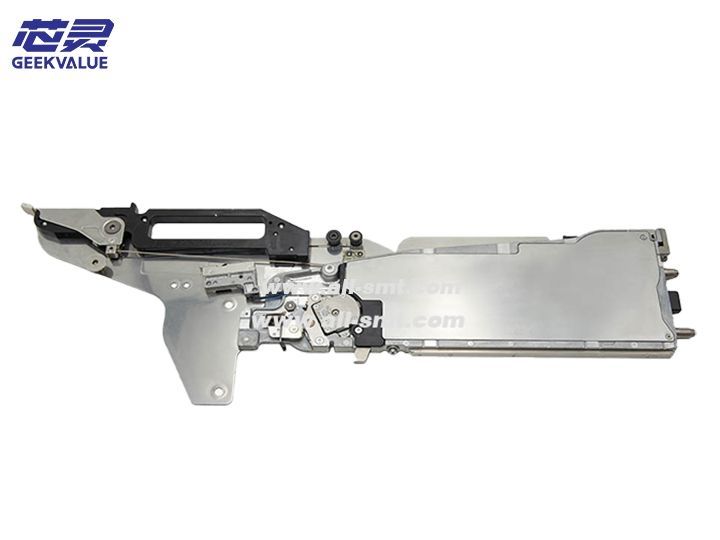

abnormal feeder;

the sensor is faulty.

Solution:

Check whether the connection of the conveyor belt of the Fuji SMT machine is normal to ensure that the conveyor belt is not blocked;

Check whether the operation of Fuji mounter material is normal, if there is a problem, repair or replace;

Check whether the sensor is damaged. Adjust or replace the sensor if necessary.

Second, Material jamming phenomenon of the smt machine

Fault performance: The Fuji chip mounter produced errors during the mounting process, resulting in inaccurate component positions.

Analysis of possible causes:

The magnetic fixation of the patch head is faulty;

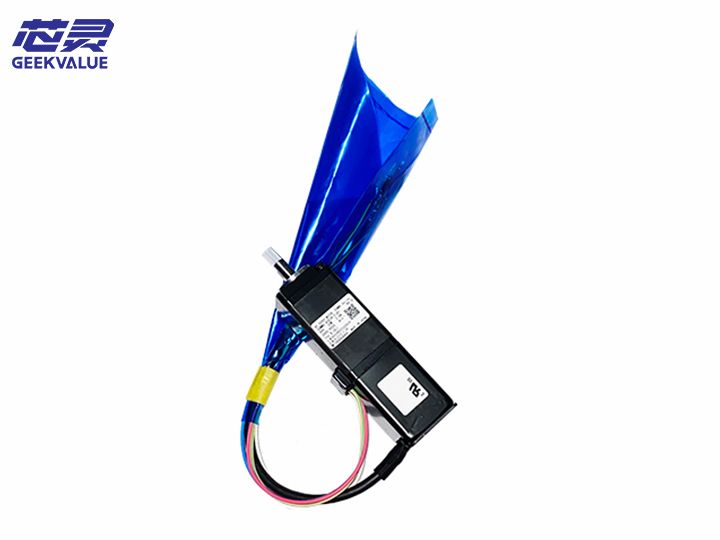

Rubber tip wear;

The CCD camera is faulty.

Solution:

Check whether the magnetic fixation of the head of the Fuji patch machine is tight, if it is loose, adjust or replace it;

Check whether the rubber nozzle is worn, and replace it with a new one if necessary;

Check whether the CCD camera of Fuji smt mounter is damaged. If there is a problem, repair or replace it.

Third, what is the installation error of the SMT machine

Fault performance: The Fuji mounter produced errors during the mounting process, resulting in inaccurate component positions.

Analysis of possible causes:

The magnetic fixation of the patch head is faulty;

Rubber tip wear;

The CCD camera is faulty.

Solution:

Check whether the magnetic fixation of the head of the Fujifilm patch machine is tight, if it is loose, adjust or replace it;

Check whether the rubber nozzle is worn, and replace it with a new one if necessary;

Check whether the CCD camera of Fuji pick and place is damaged. If there is a problem, repair or replace it.

Fourth, What is the program error of the SMT machine

Fault performance: Fuji chip machine can not run the set program normally, or there is an error message.

Analysis of possible causes:

Programming errors;

The sensor is abnormal.

Solution:

Check whether the program of Fuji smt machine is written correctly, if there is a problem, modify or rewrite;

Check whether the sensor of Fuji chip mounter is working properly, and adjust or replace it if necessary.

Fuji xpf pick and place machine may encounter various faults in daily use, but most problems can be solved with careful inspection and correct operation. However, for some serious failures, it is recommended to seek the help of professional technicians. Through effective Fuji SMT mounting machine maintenance and timely repair, we can ensure the stable operation of Fuji chip mounting machines and improve production efficiency. 👆