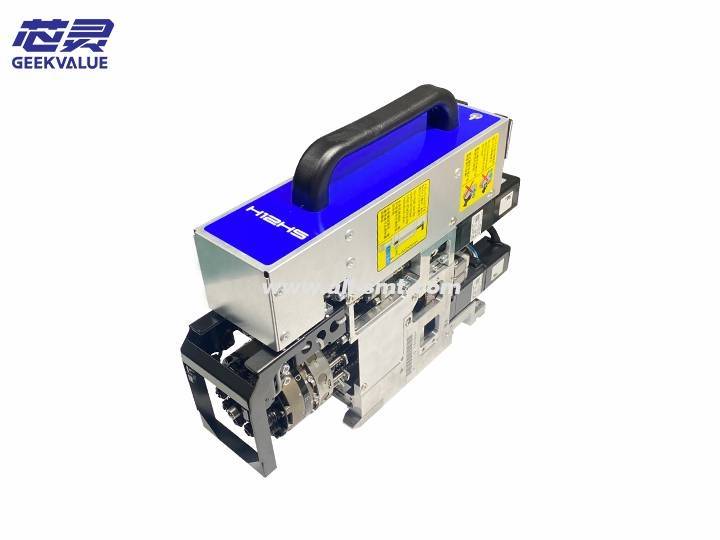

Fuji smt pick and place machine is mainly good at mounting a wide range of material sizes, which can meet the mounting needs of most electronic components. Specific to different models of Fuji mounters, they can handle component sizes and types may vary, but in general can cover from extremely small 0201 size chips to larger components such as connectors.

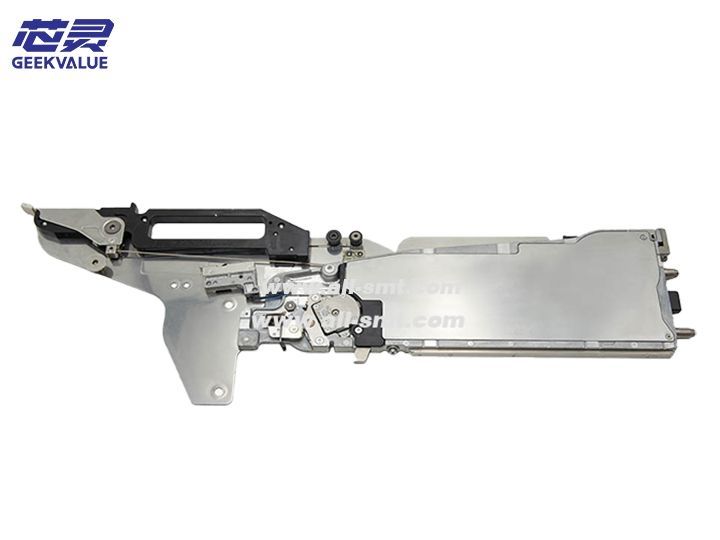

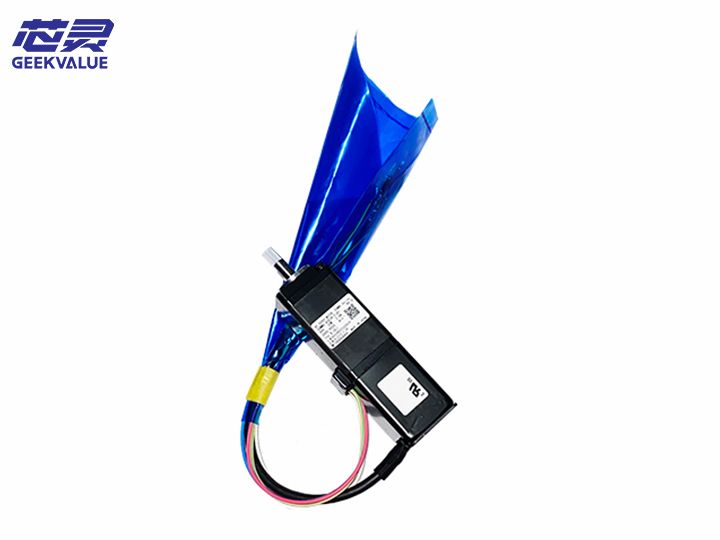

One of the core advantages of Fuji smt mounters is their highly flexible mounting capabilities, which can accommodate a wide range of sizes and types of electronic components. This flexibility is mainly due to its advanced vision system and precise control system. The vision system is able to identify and position a variety of components of different sizes, while the precise control system ensures that the components can be placed exactly in the desired position. Specific to the material size, the components that Fuji nxt smt pick and place machine can handle include but are not limited to the following common sizes:

0201 size chip: This is a very small component size used in the production of high-density circuit boards. Although the size and weight of these components are very small, Fuji smt machine are able to accurately pick up and place them through their high-precision control system and visual recognition technology.

QFP (square flat package) : This packaging method is often used in the packaging of integrated circuits, with a large number of pins, and very high requirements for mounting accuracy. Fuji mounter's high-precision mechanical arm and rotating head ensure the accurate mounting of QFP components, ensuring circuit stability and reliability.

BGA (Ball Grid Array Package) : BGA components require high mounting accuracy and welding quality due to the ball placement underneath them. Fuji smt mounter's vision system and temperature control system ensure accurate placement of BGA components to avoid bridging and welding.

Connector (connector) : This type of component is usually large, and has certain requirements for mounting pressure and accuracy. Fuji pick and place machine's flexible arm and precise control system can easily handle the mounting of such components, ensuring the stability of the connection.

In summary, Fuji smt mounters are capable of handling various sizes and types of electronic components, including 0201 size chips, QFP, BGA and Connector. Its extensive mounting capabilities, high precision and efficient production, as well as the characteristics of automation and intelligence, make Fuji mounters an indispensable production tool in the electronics manufacturing industry. For electronics manufacturers, the choice of Fuji SMT machines means access to a wider and flexible production capacity to meet diverse production needs, while ensuring high quality standards for products.