ASM placement machine is the core and most important equipment of SMT production line. In terms of price, placement machine is the most expensive in the whole line. In terms of production capacity, placement machine determines the production capacity of a line, so we usually call placement machine called placement machine. The brain of the PCB assembly line, since the placement machine is so important in the smt production line, regular maintenance of the placement machine is definitely not an exaggeration, so why should the placement machine be maintained and how should it be maintained? The following small series of Xinling Industry will tell you about this content.

The purpose of the placement machine maintenance

It is necessary to maintain the placement machine, even other equipment must be maintained. The maintenance of the placement machine is mainly to improve its service life, reduce the failure rate, ensure the stability and production efficiency of the placement, effectively reduce material loss, reduce Alarm times, improve machine production efficiency and improve production quality

How to maintain the placement machine

SMT machine regular maintenance Weekly maintenance, monthly maintenance, quarterly maintenance

Weekly maintenance:

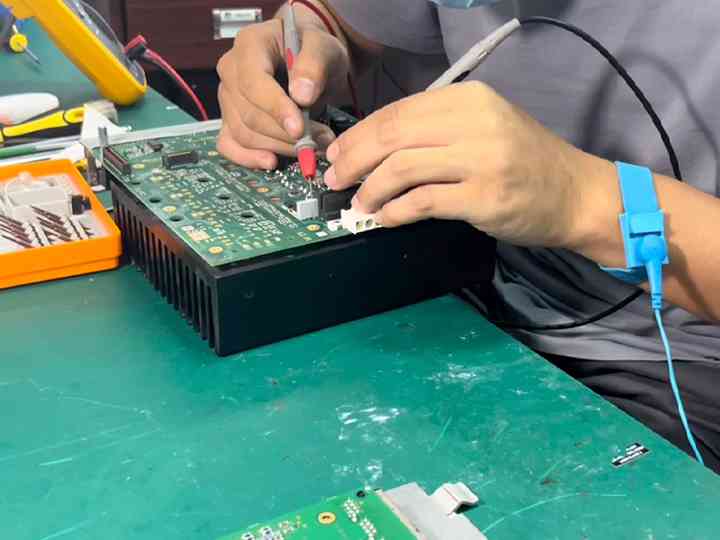

Clean the surface of the equipment; clean the surface of each sensor, clean and disassemble the dust and dirt on the surface of the machine and circuit board, so as to avoid poor heat dissipation inside the machine due to dust and dirt, causing the electrical part to overheat and burn out, check whether the screw There is looseness;

Monthly maintenance:

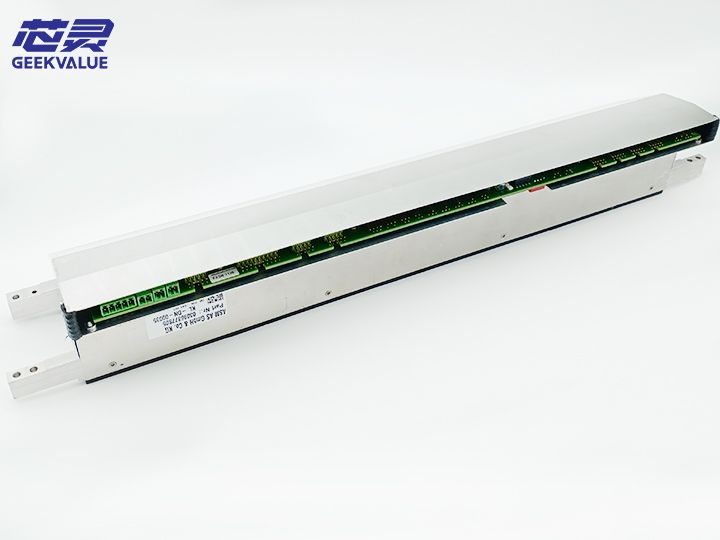

Add lubricating oil to the moving parts of the machine, clean and lubricate, (such as: screw, guide rail, slider, transmission belt, motor coupling, etc.), if the machine runs for a long time, due to environmental factors, there will be dust sticking to the moving parts Parts, replace the lubricating oil for the X and Y axes; check whether the grounding wires are in good contact; check whether the suction nozzle is blocked and add liquid oil to detect and clean the camera lens;

Quarterly maintenance:

Check the state of the patch head on the HCS instrument and maintain it, and whether the power supply of the electric box is in good contact; Check the wear and tear of each component of the equipment, and replace and overhaul (such as: wear of machine lines, wear of cable racks, motors, lead screws) Loosening of fixing screws, etc., some mechanical parts do not move well, parameter settings are wrong, etc.).

Many factories do not stop the equipment 365 days a year, and the technicians have little rest. The factory technicians mainly deal with simple operations and faults on the production line, and they are not technically professional. After all, maintaining the normal operation of the equipment is the most important. There are too many opportunities to repair the machine. Guangdong Xinling Industrial Co., Ltd. has a professional technical team. It has undertaken the annual maintenance and equipment relocation services of many large companies. SMT manufacturers of chip machines reduce costs, improve production efficiency, and provide long-term technical services for equipment (expert-level engineers can provide equipment repair, maintenance, modification, CPK testing, MAPPING calibration, production efficiency improvement, board motor maintenance, Feida Maintenance, patch head maintenance, technical training and other one-stop services).