The placement machine is actually a high-precision industrial robot, which is a high-tech achievement of electromechanical integration, photoelectric integration,

and computer control technology. It realizes high-speed, high-precision, and intelligent electronic placement equipment. There are obvious differences in structure.

According to the action mode of the placement machine, it can be divided into boom type arch type and turret type;

According to the degree of automation, it can be divided into semi-automatic manual, semi-automatic and fully automatic placement machines;

According to the function and speed of the placement machine, it can be divided into high-precision multi-function placement machine (also known as general-purpose

machine, mainly attaching high-precision, narrow pitch, large-size and irregular devices) and high-speed placement machine (mainly paste small components);

According to the position of the placement machine feeder and the number of placement heads, it can be divided into mainframe, small and medium-sized machines and

modular machines.

Although there are so many types of placement machines, their basic structure is the same

It generally consists of the following five parts:

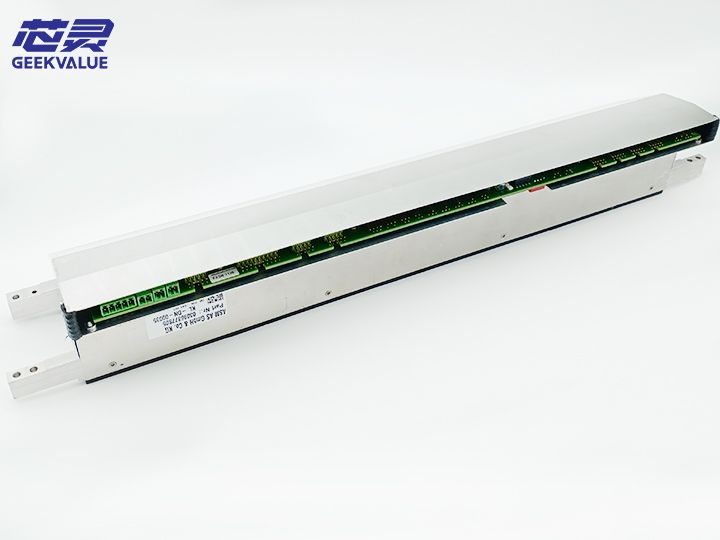

1. Mechanical system, including mechanical casing, transmission system and servo positioning system. The mechanical shell is the skeleton and skin of the placement machine,

which plays the role of support and protection. The transmission system is responsible for transferring the PCB. The servo positioning system supports the placement head to

ensure its precise positioning and precise movement.

2. Detection and identification system, including identification system and various sensors. The identification system identifies PCBs, feeders and components. Various sensors are

constantly detecting the running status and data of the machine.

3. Feeding equipment, supplying the components required by the placement head, material name, placement position, adsorption position, feeding step and feeding angle and

other key parameters.

Fourth, the placement head, which is the most critical component of the placement machine, accurately completes the work of picking and placement.

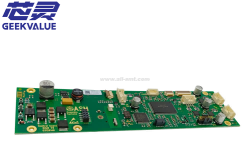

5. The computer control system, the command center of the placement machine, like the human brain, records a large number of machine parameters, processes the signals of the

identification equipment and various sensors, and controls the placement action of the placement machine according to the placement program.

Service: Guangdong Geekvalue Industrial Co., Ltd. has specialized in supplying placement machines for 15 years, providing one-stop solutions for sales, leasing and maintenance

of placement machines.

Advantages: There are a large number of placement machines in stock for a long time, covering medium-speed machines, general-purpose machines and high-speed machines.

The price advantage is large and the delivery speed is fast. The professional technical team escorts the equipment and makes customers more comfortable and at ease.