placement machine is a kind of equipment widely used in electronic manufacturing industry, and its parts replacement is an important link to ensure the normal operation

of the equipment. However, with the increase of use time, the accessories of the placement machine may be worn, aged or damaged. In this case, timely replacement of accessories

is the key to ensure the normal operation of the placement machine. The following are the main points about the replacement of placement machine accessories.

1. Determine the faulty part: First, it is necessary to determine which part the fault occurs by observing the operation of the placement machine, checking the error report,

or performing various tests. You can refer to the technical manual of the placement machine or consult the supplier for more help.

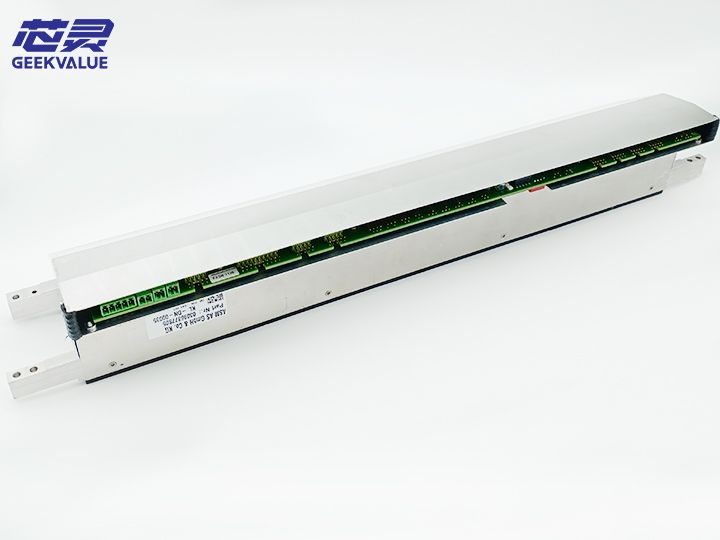

2. Sourcing the right parts: Once the faulty part has been identified, a replacement part that matches the original part needs to be purchased. It is recommended to choose

original accessories or accessories from certified suppliers to ensure that their quality and performance meet the requirements of the placement machine.

3. Turn off the placement machine and disconnect the power supply: Before replacing the accessories, be sure to turn off the placement machine and disconnect the power

supply to ensure safe operation and avoid any electric shock or other accidents.

4. Disassemble the faulty parts: Use appropriate tools and methods to remove the faulty parts from the placement machine in accordance with the technical manual or instructions

of the placement machine. Be careful during disassembly to avoid damage to other components.

5. Install new accessories: After removing the faulty accessories, install new accessories into the mounter. Make sure that new accessories match the specifications and requirements

of the pick and place machine and are installed correctly. Make correct connections and fixes according to the guidance of the technical manual or instruction manual.

6. Perform test and calibration: After replacing the parts, restart the placement machine and perform test and calibration. Testing can include running a series of samples or simulating

a production process to ensure proper machine operation after component changes. Calibration can include calibrating sensors, adjusting parameters, etc. to ensure the accuracy and

stability of the placement machine.

7. Record the replacement process: In the process of replacing accessories, it is recommended to record the key steps and operations. This provides a reference for future maintenance

and troubleshooting, and helps improve efficiency and accuracy.

8. Regular maintenance and maintenance: Part replacement is only part of the maintenance of the placement machine. In order to keep the placement machine in good condition,

regular maintenance and maintenance work, such as cleaning, lubrication, inspection and adjustment, etc. are required.

To sum up, the replacement of placement machine parts requires determining the faulty parts, purchasing suitable parts, shutting down the placement machine and disconnecting

the power supply, disassembling the faulty parts, installing new parts, performing tests and calibrations, recording the replacement process, and regular maintenance and maintenance .

The correct execution of the above steps can ensure the normal operation of the placement machine and improve work efficiency and quality.