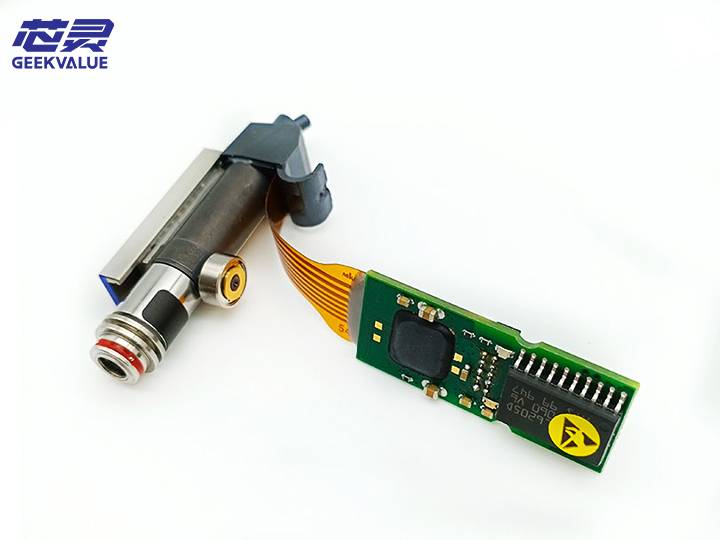

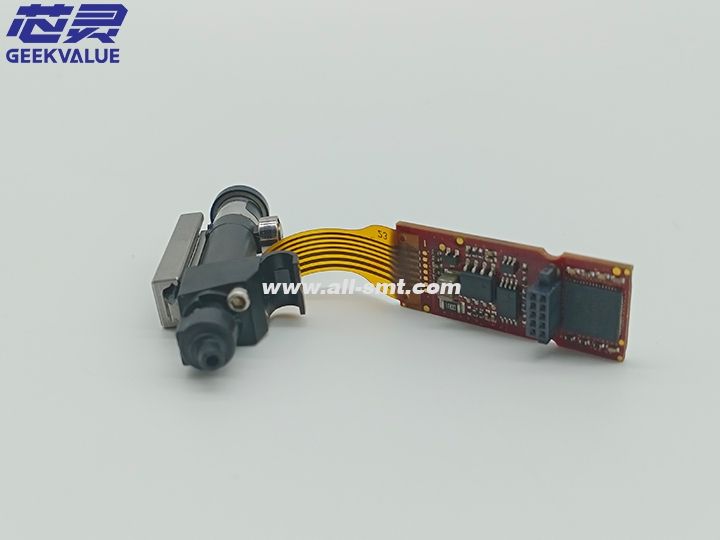

The DP motor is one of the key components in the placement machine, which drives the movement of the suction nozzle by controlling the rotation of the motor.

When the DP motor is working properly, the nozzle can pick and place components accurately. If the DP motor fails, it will result in the inability to access the

suction nozzle normally, which will affect the normal operation of the placement machine. This article will introduce some troubleshooting methods

for the failure of the DP motor to pick up the nozzle, so as to help you solve the problem quickly.

When the DP motor fails, it can cause the following problems:

1. Incoherent movement of the suction nozzle: DP motor failure may cause the movement of the suction nozzle to become incoherent, thus affecting the running

stability of the placement machine.

2. The speed of the nozzle is unstable: DP motor failure may cause the speed of the nozzle to be unstable, and there may be fast or slow nozzle movement, which

will affect the accuracy of pasting the components.

3. The suction nozzle stops moving: DP motor failure may cause the suction nozzle to stop moving, resulting in the placement machine not working properly.

4. Increased nozzle noise: DP motor failure may cause abnormal noise when the nozzle moves, which may be caused by damage or wear of the internal parts of the motor.

5. Inaccurate placement of the patch: DP motor failure may lead to inaccurate movement of the suction nozzle, resulting in inaccurate placement of the patch,

which may be offset or misplaced.

For the failure of the DP motor nozzle, the following solutions can be taken.

1. Check the connection

First, we need to check the connection between the DP motor and the nozzle. Make sure the cables are not loose or damaged. If there is a problem with the connecting

line, it should be replaced or repaired in time. At the same time, also check that the connector is inserted correctly to ensure a stable connection.

2. Check the nozzle status

Second, we need to check the status of the nozzle. Occasionally, the nozzle may become clogged with foreign objects, preventing proper access to components.

Use a nozzle cleaner or cotton swab to clean the nozzle and make sure it is unobstructed. In addition, check whether the suction nozzle is worn or deformed,

and if so, replace the suction nozzle in time.

3. Check the nozzle vacuum source

If there is no problem with the connection and the nozzle, then we need to check the vacuum source of the nozzle. Make sure the vacuum source is working properly

and providing adequate suction. It can be confirmed by checking components such as vacuum pump, vacuum line and filter. If a problem is found, repair or replace

the faulty part in time.

4. Check the DP motor

If none of the above methods solve the problem, the fault may be in the DP motor itself. In this case, it is recommended to contact a professional maintenance service

provider, such as Xinling Industrial. They have experienced technicians who can perform comprehensive inspections and repairs on DP motors. They may need to

disassemble the DP motor and examine the condition of its internal parts to determine the source of the problem. According to the results of the inspection, they

can provide corresponding solutions and carry out repairs or replace faulty parts.

During the maintenance process, Geekvalue Industry will also ensure that all operations comply with safety regulations, and provide post-maintenance testing and debugging.

Their goal is to ensure equipment is back up and running with minimal downtime.