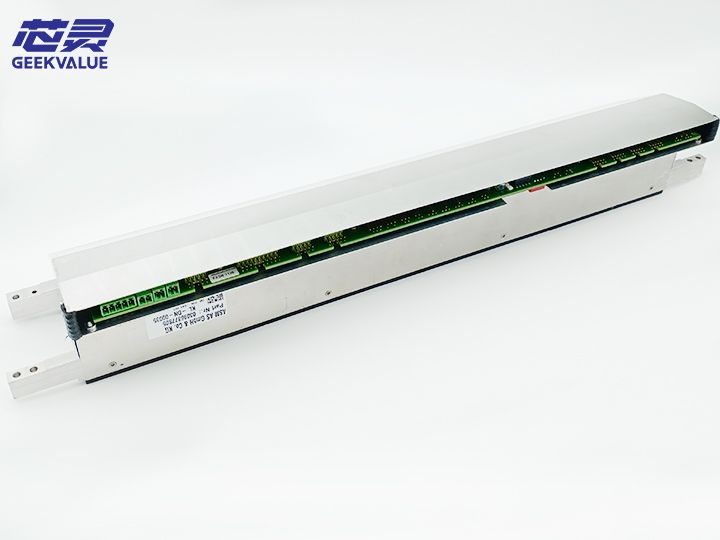

Today, Geekvalue Industry will share with you the splicing of Siemens SIPLACE placement machine with loading material, I believe it will be helpful to you!

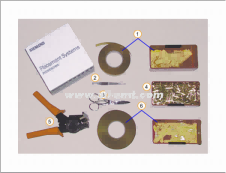

Required tools and materials

The following tools and materials are necessary for loading the splice tape

(1) tape (narrow)

(2) Tweezers

(3) Scissors

(4) Sheet rivets (copper sheets) for connecting strips

(5) Splicing jaws (6) Tape (wide)

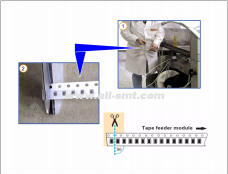

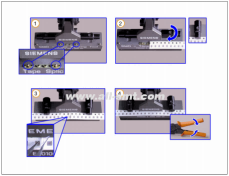

Prepare the end of the strip

Strip end:

(1) The so-called tail end of the tape refers to the end of the roll that is about to be used up in the feeder

(2) Cut off the tape from the center point of two adjacent component positions (the center of the small round hole in the figure). Please ensure that there are materials

in all the component holes on the tape. Note: When receiving the material, it is about to The finished roll must have a long enough length to expose the feeder,

otherwise the machine will be easily stopped due to the action of receiving the material

Prepare the start of a new strip

New tape start:

(1) Tear off the film on the surface of the tape about the width of one material level

(2) Cut off the tape from the center point of two adjacent component positions (the center of the small round hole in the figure). Please make sure that there are materials

in all the component holes on the tape and pay special attention to whether the first material is normal. Note: Do not cut the material tape directly, the film on the surface

of the material tape must leave a small section (as shown in the picture)

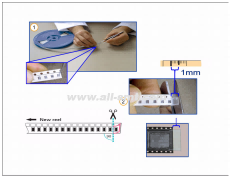

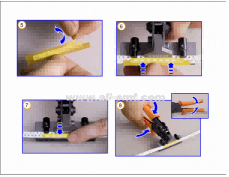

splicing tape

(1) Put the copper piece on the positioning pin of the splicing clamp, with the protruding side facing up. Note: The small picture shows the relative position of the small

copper piece and the pin

(2) Press down about 1/2 of the copper sheet with the end of the old material tape (the coil material being used by the feeder), and rotate the locking device in the direction

of the arrow in the figure

(3) Press the remaining 1/2 of the copper sheet with the starting end of the new tape (new reel that has not been used), and lock it tightly. Let the film reserved at the front

of the new tape cover the old tape. Note: The small picture shows the condition of the film cover

(4) Press the splicing clamp until the last self-locking position

(5) Tear off half of the protective tape. Do not touch the sticky side of the tape

(6) Carefully stick the tape on the upper surface of the tape as shown in the picture and press it tightly.

(7) Tear off the other half of the tape protection layer and press it tightly

(8) Press the material receiving pliers to the bottom, and when you let go, the material receiving pliers will automatically release, and the material receiving is completed

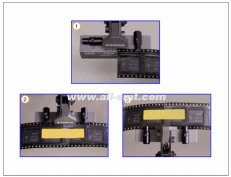

splicing wide tape

We do basically the same thing with wide strips

(1) Press down about 1/2 of the copper sheet with the end of the old material tape (the coil being used by the feeder), and rotate the locking device in the direction of the arrow in the figure

(2) Splice one side of the strip first. Note that a wide tape is used here (3) Then connect the other side of the strip with a copper sheet and splicing pliers

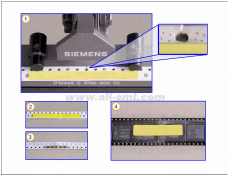

Check the quality of the receiving material

How to distinguish whether the effect of receiving materials meets the requirements

(1) If the splicing is correct, we can see traces of splicing on the surface of the tape (as shown in the picture)

(2) Front view of 8mm tape after splicing

(3) Legend of the back side of the 8mm material tape after splicing

(4) Front view of 24mm tape after splicing

The above is the sharing about the splicing of Siemens Siemens SIPLACE placement machine with loading material. If you want to know more about the training information

of Siemens placement machine, please pay attention to Xinling Industry!