As a high-performance surface mount equipment, Siemens D4 placement machine has excellent placement ability and advanced technical features.

This article will deeply analyze the parameter details of the D4 placement machine, and focus on its advantages in the field of placement, providing

readers with a comprehensive understanding.

Siemens D4 placement machine parameter details:

1. SMT speed:

The placement speed of Siemens D4 placement machine can reach up to 60,000 components per hour, completing the placement task quickly and

efficiently. This high speed can greatly improve production efficiency and reduce production time and cost.

2. Minimum component size:

The D4 placement machine can handle components with a minimum size of 01005, which means that it can mount very small components and meet

the miniaturization requirements of modern electronic products.

3. Component type adaptability:

The D4 placement machine is widely applicable to various types of components, including SMT, Ball Post, BGA and QFP, etc. This flexibility makes it

suitable for different kinds of electronic product manufacturing.

4. High precision positioning:

The D4 placement machine is equipped with an advanced visual positioning system, which can achieve high-precision component positioning. This

ensures placement accuracy and consistency, improving product quality.

5. Automatic feeding system:

The automatic feeding system of the D4 placement machine can accommodate components of various specifications and realize the automatic feeding

process. This feature greatly reduces the workload of operators and improves production efficiency.

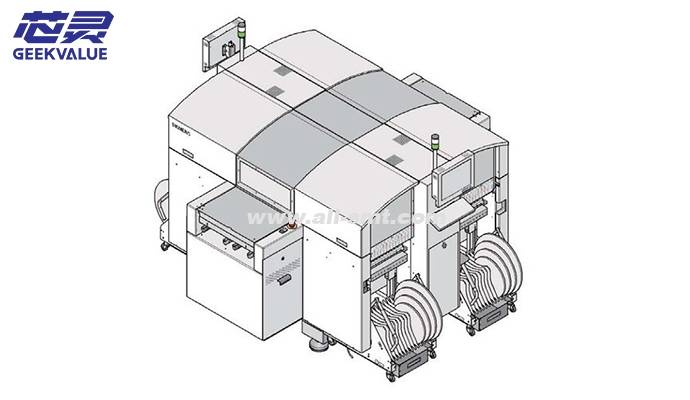

D4 placement machine

Analysis of the advantages of Siemens D4 placement machine:

1. Highly automated:

The D 4 placement machine adopts advanced automation technology to realize functions such as automatic feeding, automatic positioning and automatic

placement, which reduces the need for manual operation and improves production efficiency. At the same time, the feature of automation also reduces the

burden on operators and reduces errors caused by human factors.

2. High-speed patch:

The D4 placement machine has high-speed placement capabilities, and can mount up to 60,000 components per hour, which greatly improves production

efficiency. In the fast pace of today's electronic product updates and iterations, high-speed placement can meet the market's demand for mass production

and shorten the time to market of products.

3. High-precision placement:

The D4 placement machine is equipped with an advanced visual positioning system, which can achieve high-precision component positioning. This ensures

the accuracy and consistency of the patch and improves the quality of the product. High-precision placement also makes the spacing between components

smaller, which further meets the needs of miniaturization of electronic products.

4. Wide adaptability:

The D4 placement machine has a wide range of adaptability and can handle various types of components, including SMT, Ball Post, BGA and QFP. This makes

it suitable for different kinds of electronic product manufacturing, meeting the diverse needs of the market.

5. High reliability:

As a well-known manufacturer of electronic equipment, Siemens has guaranteed the quality and reliability of the D4 placement machine. Its advanced technology

and strict quality control enable the placement machine to have a long service life and stable performance, reducing maintenance costs and the risk of production downtime.

6. Flexibility:

The D4 placement machine has flexible production capacity and can be adjusted and reset according to different product requirements. It can adapt to electronic

components of different sizes and shapes, as well as different placement process requirements. This flexibility makes the production line more adaptable to market

changes and customer needs, improving the adaptability and competitiveness of the production line.

7. Save space:

The D4 placement machine has a compact design and takes up little space. This allows it to be easily installed in limited factory spaces for efficient space utilization.

For factories, this means that more production equipment can be arranged to increase production capacity.

8. Environmental protection and energy saving:

The D4 placement machine adopts advanced energy management technology to achieve energy saving and environmental protection. It automatically adjusts energy

consumption to optimize energy use based on actual workloads. This not only reduces energy waste, but also reduces the impact on the environment, meeting the

requirements of sustainable development.

All in all, Siemens D4 placement machine has the advantages of high-speed placement, high-precision placement, wide adaptability, high reliability, flexibility, space saving,

environmental protection and energy saving. It is the key equipment in the manufacture of electronic products, which can improve production efficiency and product quality,

meet the needs of the market, and bring greater competitive advantages to enterprises. If you want to know the comparison between this placement machine and other

placement machines, you can tell us in the comment area, and we will analyze it for you in the next issue.