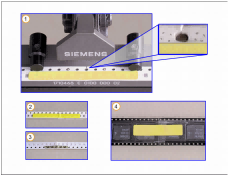

There are many Siemens placement machine models, the following are several well-known Siemens placement machine models:

SIPLACE D series: including several models such as D1, D2, D3, D4, etc., is the most important product series of placement machines of Siemens. D series models can complete the assembly of SMD and THT (Through Hole Technology, plug-in) components on one device.

SIPLACE S series: including several models such as S20, S25, and S27, it is a placement machine suitable for medium-scale mass production. The S series models are highly flexible and can adapt to different production needs.

SIPLACE X series: including several models such as X4, X5, X2, etc., is the latest product series of placement machines from Siemens. X series models have higher throughput, higher precision and higher flexibility, suitable for high-speed, high-precision and high-reliability production needs.

SIPLACE F series: including several models such as F4, F5, F2, etc., are placement machines for high-speed SMD placement. The F series models feature ultra-high throughput and high-precision placement capabilities.

The above are several common models of Siemens placement machines. Each model has different features and advantages, and the appropriate model can be selected according to different production needs.

Features of each series:

SIPLACE D-Series:

The D series models can complete the assembly of SMD and THT components on one device, which is suitable for flexible mixed production.

Equipped with unique SIPLACE X gears and high-speed motors, it has fast and accurate placement capabilities.

It has the characteristics of flexible unit combination, efficient automatic line change, automatic correction and reliable placement control system, which can greatly improve production efficiency.

SIPLACE S-Series:

The S series models are highly flexible, able to adapt to different production needs and provide fast production switching.

Equipped with intelligent placement control system and SIPLACE X gear, it can provide high-quality placement performance.

It has the characteristics of flexible plate loading scheme, fast automatic line change and automatic correction, low noise and low vibration, etc., which provides a guarantee for efficient and stable production.

SIPLACE X-Series:

The X series models have ultra-high output, higher precision and higher flexibility, and are suitable for high-speed, high-precision and high-reliability production requirements.

Equipped with leading modular platform, multi-axis linear drive system, SIPLACE X gear and intelligent placement control system, it can provide excellent placement performance.

With the characteristics of brand-new robot operating system, highly automated operation process, fast product replacement and automatic line change, it can greatly improve production efficiency and reduce production cost.

SIPLACE F-Series:

The F series models are placement machines for high-speed SMD placement, with ultra-high throughput and high-precision placement capabilities.

Equipped with unique SIPLACE X gear, high-speed motor and intelligent placement control system, it can achieve fast, accurate and stable placement.

It has the characteristics of fast line change, automatic correction and automatic detection, which can greatly improve production efficiency.