When you're running a surface-mount technology (SMT) production line, there’s one key component that can make or break your entire operation: the feeder. This is the system that ensures your components are accurately delivered to the pick-and-place machines, which then place them precisely on your printed circuit boards (PCBs). In the fast-paced world of electronics manufacturing, you need feeders that work seamlessly, consistently, and reliably.

That’s where Sony Feeder SMT steps in. Known for its high-quality, precise, and durable performance, the Sony Feeder SMT system has become an essential tool for manufacturers looking to maximize production efficiency and minimize downtime. If you're aiming to take your SMT assembly line to the next level, here's why Sony Feeder SMT should be your top choice—and why you should get in touch with us today to make the purchase.

What is Sony Feeder SMT and Why Does It Matter?

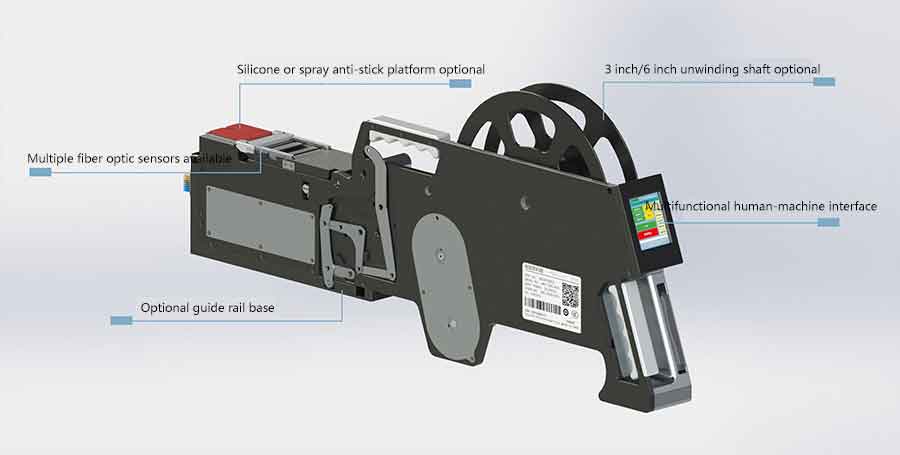

At its core, the Sony Feeder SMT system is designed to feed electronic components into your pick-and-place machines, which are used in PCB assembly. These feeders are crucial because if they don't deliver components accurately and reliably, your assembly line can experience delays, errors, or even total breakdowns.

The Sony Feeder SMT system is engineered for precision—something that's essential in SMT assembly, where even the smallest misplacement of a component can ruin an entire production run. Whether you’re working with tiny resistors, capacitors, or complex integrated circuits (ICs), the Sony Feeder SMT system ensures that each component is fed accurately to the machine, significantly reducing errors.

Why Choose Sony Feeder SMT for Your Business?

1. Reliability and Longevity

When it comes to manufacturing equipment, reliability is key. You can’t afford to have your feeders malfunctioning, as this will cause significant delays and impact your bottom line. Fortunately, Sony feeders are built to last. These systems are designed with high-quality materials and advanced engineering to withstand the demands of continuous operation in high-speed environments.

Whether you’re running a small batch or ramping up for large-scale production, the Sony Feeder SMT system won’t let you down. It’s built for long-term reliability, ensuring you get maximum uptime and minimal maintenance, which means fewer interruptions to your production line.

2. Precision and Accuracy

In SMT assembly, precision is everything. If a component isn’t placed in exactly the right spot, the entire PCB could fail. That’s why the Sony Feeder SMT system is a game-changer. These feeders are designed to deliver components with absolute precision, ensuring that every part is placed exactly where it needs to be. This precision minimizes the chance of errors and defects in the final product.

With Sony feeders, you can rest easy knowing that your production process will be smooth, with accurate placements every single time. This level of accuracy not only saves you time but also reduces the likelihood of costly mistakes or rework, which can quickly add up.

3. Flexibility to Handle a Wide Range of Components

One of the standout features of the Sony Feeder SMT system is its flexibility. Sony feeders are capable of handling a variety of components, from the smallest SMD parts to larger, more complex ones. This means you can use the same system for different types of products, reducing the need for multiple types of feeders.

This adaptability is particularly beneficial for businesses that manufacture a wide range of products. Whether you're assembling consumer electronics, automotive parts, or medical devices, the Sony Feeder SMT can handle a diverse array of components without compromising performance.

4. Seamless Integration with Your Existing Systems

Many manufacturers are hesitant about upgrading their equipment because they fear it will disrupt their current setup. The good news is that Sony Feeder SMT systems are designed to integrate smoothly with your existing SMT production lines. Whether you’re adding feeders to a brand-new setup or upgrading your older systems, Sony feeders are compatible with a wide variety of pick-and-place machines.

This means you don’t have to worry about overhauling your entire production line. You can easily upgrade your system without interrupting your workflow, making the Sony Feeder SMT a hassle-free solution for businesses of all sizes.

5. Cost-Effective and Efficient

While quality equipment comes at a price, Sony Feeder SMT systems offer great value for money. They’re competitively priced and designed to provide excellent return on investment (ROI). With minimal maintenance, long-lasting durability, and increased production efficiency, these feeders ultimately save you money over time.

In fact, the increase in production speed and accuracy that comes with Sony feeders means that you'll see more units produced in less time, which can significantly boost your profitability. Plus, since the feeders are built to last, you won’t have to worry about frequent replacements or repairs, further lowering your overall costs.

How Sony Feeder SMT Improves Your Production Process

1. Increased Production Speed

With Sony Feeder SMT, one of the immediate benefits you'll notice is a significant increase in production speed. These feeders are engineered to work quickly and efficiently, allowing the pick-and-place machines to operate at peak performance. Faster feeding means your assembly line can run at higher speeds, reducing cycle times and increasing throughput.

As production speeds up, you’ll be able to meet growing demands and shorten lead times, which is a huge advantage in today’s competitive market.

2. Higher Product Quality

The precision and reliability of the Sony Feeder SMT system result in fewer defects and better overall product quality. When components are fed accurately and consistently, your pick-and-place machines can assemble the boards with fewer errors. This leads to fewer rework costs and a higher-quality final product, which means your customers get exactly what they need, when they need it.

3. Lower Maintenance Costs

One of the standout features of Sony feeders is their low maintenance needs. Because they are designed with high-quality materials and components, these feeders are less likely to require frequent repairs or replacements. This means less downtime, fewer maintenance costs, and less disruption to your production line.

By investing in Sony Feeder SMT, you’re not just buying a piece of equipment—you’re making an investment in long-term efficiency and profitability.

Why Contact Us for Your Sony Feeder SMT Purchase?

Now that you know how valuable the Sony Feeder SMT system can be for your production line, it’s time to take the next step. We’re here to help you find the perfect Sony Feeder SMT system for your needs, whether you’re looking to upgrade an existing line or invest in new equipment.

Our team has years of experience in the SMT industry, and we understand the unique needs of businesses like yours. When you contact us, we’ll guide you through the process and ensure you get the best feeder system for your operation.

Don’t wait any longer—reach out to us today and see how the Sony Feeder SMT system can transform your production line. Our friendly experts are ready to help you choose, purchase, and install your new system, so you can start seeing the benefits immediately.