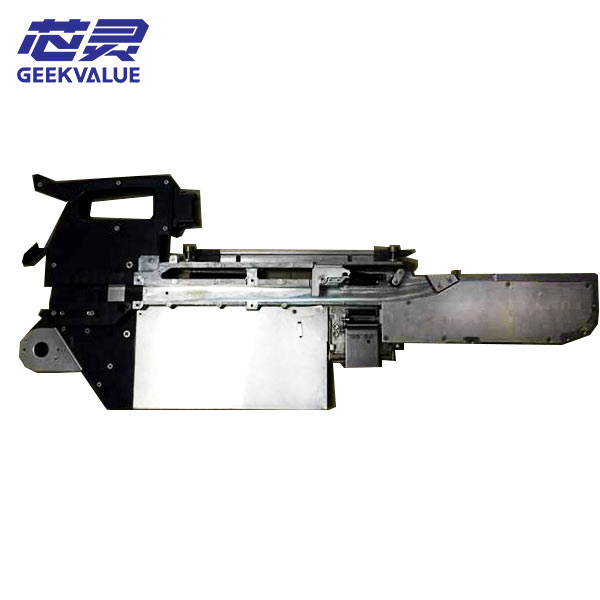

Главна функција 8мм електричног улагача Иамаха СМТ машине је да обезбеди електронске материјале за СМТ машину, обезбеђујући да СМТ машина може прецизно и ефикасно да обавља СМТ операције.

Принцип рада и карактеристике електричне хранилице

Електрични улагач преноси и храни материјале преко електронског електромагнетног погонског мотора, који има високу тачност и стабилност. У поређењу са пнеуматским хранилицама, електрични хранилице су тачније у преносу материјала малих димензија јер губе мање негативног притиска током процеса формирања и излаза, што је погодно за пренос материјала малих димензија.

Примена електричних хранилица у СМТ машинама

Када се електрични улагач користи на СМТ машини, улагач са материјалима треба да се учита у интерфејс СМТ машине. Функција улагача је да инсталира СМД СМТ компоненте на улагач, а улагач затим обезбеђује компоненте за СМТ машину за СМТ. Уобичајени типови хранилица укључују траку, цев, послужавник (такође познат као послужавник за вафле) итд.

Предности електричног улагача Иамаха СМТ машине

Једноставан за употребу: једноставан рад, потребна је само једноставна обука за почетак, а опрема је веома стабилна и није склона кваровима. Стабилне перформансе: Аутоматски радни режим побољшава тачност рада и погодан је за различите процесне операције.

Добар ефекат хлађења: може добро заштитити унутрашњу електронску опрему и продужити век трајања опреме.

Висока сигурност: Има више сигурносних заштитних механизама који осигуравају сигурност оператера