Mashiinka meelaynta ASM waa ubucda iyo qalabka ugu muhiimsan ee khadka wax soo saarka SMT. Marka la eego qiimaha, mashiinka meelaynta ayaa ah kan ugu qaalisan khadka oo dhan. Marka la eego awoodda wax-soo-saarka, mashiinka meelaynta ayaa go'aamiya awoodda wax-soo-saarka ee xariiqda, sidaas darteed waxaan inta badan u yeernaa mashiinka meelaynta ee loo yaqaan 'placement machine'. Maskaxda khadka isku dhafka ah ee PCB, maadaama mashiinka meelaynta uu aad muhiim ugu yahay khadka wax soo saarka smt, dayactirka joogtada ah ee mashiinka meelaynta hubaal maahan buunbuunin, haddaba maxaa loo ilaalinayaa mashiinka meelaynta iyo sidee loo ilaalinayaa? Taxanaha yar yar ee soo socda ee Warshadaha Xinling ayaa kuu sheegi doona waxa ku saabsan.

Ujeedada dayactirka mashiinka meelaynta

Waa lagama maarmaan in la ilaaliyo mashiinka meelaynta, xitaa qalabka kale waa in la ilaaliyaa. Dayactirka mashiinka meelaynta ayaa inta badan ah in la wanaajiyo nolosheeda adeegga, la yareeyo heerka fashilka, hubinta xasiloonida iyo wax-soo-saarka meelaynta, si wax ku ool ah u yareeyo khasaaraha alaabta, yaraynta wakhtiyada Alarm, hagaajinta waxtarka wax soo saarka mashiinka iyo hagaajinta tayada wax soo saarka

Sida loo ilaaliyo mashiinka meelaynta

Mashiinka SMT dayactirka joogtada ah ee dayactirka toddobaadlaha ah, dayactirka bilaha ah, dayactirka saddexdii biloodba mar

Dayactirka toddobaadlaha ah:

Nadiifi dusha sare ee qalabka; nadiifi dusha sare ee dareemayaal kasta, nadiifi oo kala saar boodhka iyo wasakhda dusha sare ee mishiinka iyo guddiga wareegga, si looga fogaado kulaylka xun ee gudaha mishiinka sababtoo ah boodhka iyo wasakhda, taas oo keenaysa in qaybta korantadu ay kululaato oo gubato. Hubi in furku uu dabacsan yahay;

Dayactirka bishii:

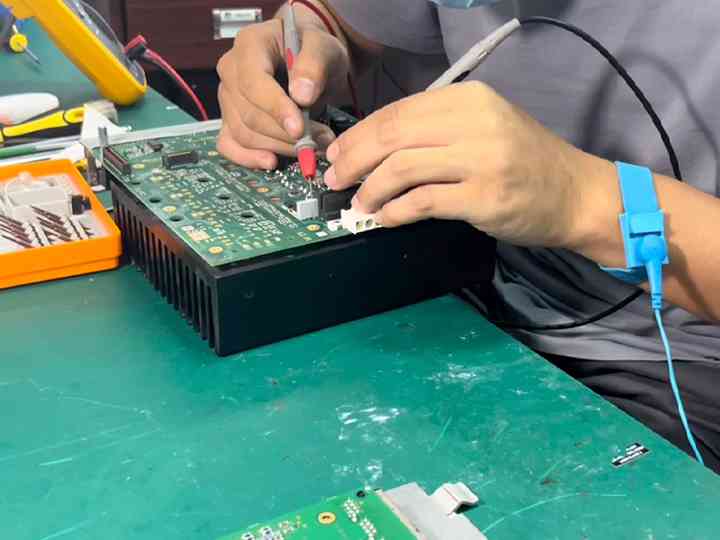

Ku dar saliidda saliidda ee qaybaha dhaqaaqa ee mishiinka, nadiifi oo saliid, (sida: birta, birta hagaha, slider, suunka gudbinta, isku xidhka mootada, iwm.), haddii mashiinku uu socdo wakhti dheer, sababo deegaanka awgeed. waxaa jiri doona boodh ku dheggan qaybaha dhaqdhaqaaqa, beddel saliidda saliidda ee faashashka X iyo Y; Hubi in fiilooyinka dhulka la dhigay ay xiriir wanaagsan leeyihiin; hubi in sanbabada nuugiddu ay xanniban tahay oo ku dar saliid dareere ah si loo ogaado oo loo nadiifiyo muraayadda kamarada;

Dayactirka saddex-biloodlaha ah:

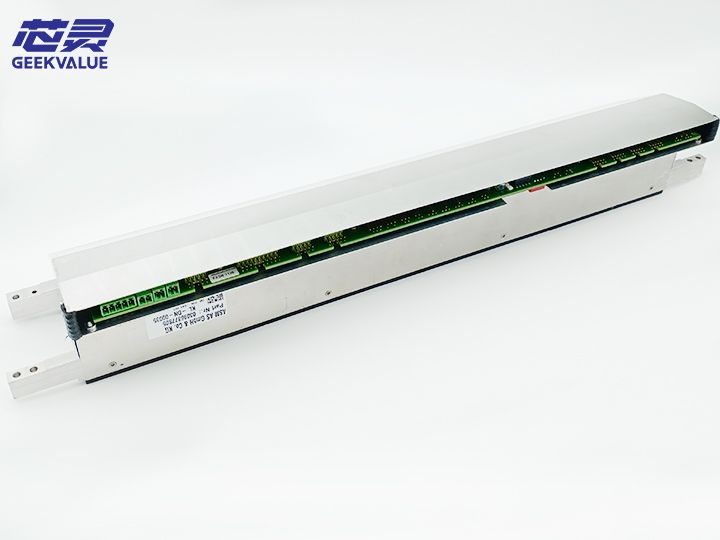

Hubi xaaladda madaxa balastar ee qalabka HCS oo ilaali, iyo in sahayda korantada ee sanduuqa korantada ay si fiican u xiriirto; Hubi jeexjeexa iyo jeexjeexa qayb kasta oo ka mid ah qalabka, oo beddel oo dib u habeyn (sida: xidhashada xadhkaha mishiinka, xidhashada xargaha fiilooyinka, matoorada, boolasha rasaasta) Dejinta furayaasha hagaajinta, iwm, qaybo makaanik ah si fiican uma socdaan , Settings parameter waa khalad, iwm.).

Warshado badan ma joojiyaan qalabka 365 maalmood sannadkii, farsamayaqaanadu nasasho yar ayay haystaan. Farsamayaqaannada warshaduhu waxay inta badan wax ka qabtaan hawlgallada fudud iyo cilladaha khadka wax-soo-saarka, mana aha kuwo farsamo ahaan xirfad leh. Ka dib oo dhan, ilaalinta shaqada caadiga ah ee qalabku waa tan ugu muhiimsan. Waxaa jira fursado badan oo lagu hagaajin karo mashiinka. Guangdong Xinling Industrial Co., Ltd. waxay leedahay koox farsamo oo xirfad leh. Waxa ay qabatay dayactirka iyo raridda qalabka sanadlaha ah ee shirkado badan oo waaweyn. Soo-saareyaasha SMT ee mashiinnada chip-ka waxay yareeyaan kharashaadka, waxay hagaajiyaan hufnaanta wax soo saarka, waxayna bixiyaan adeegyo farsamo oo waqti-dheer ah oo loogu talagalay qalabka (injineerada heerka-khabiirku waxay ku siin karaan dayactirka qalabka, dayactirka, wax ka beddelka, tijaabinta CPK, cabbiridda khariideynta, hagaajinta hufnaanta wax soo saarka, dayactirka guddiga, Feida Dayactirka, dayactirka madaxa balastar, tababar farsamo iyo adeegyo kale oo meel-joojin ah).