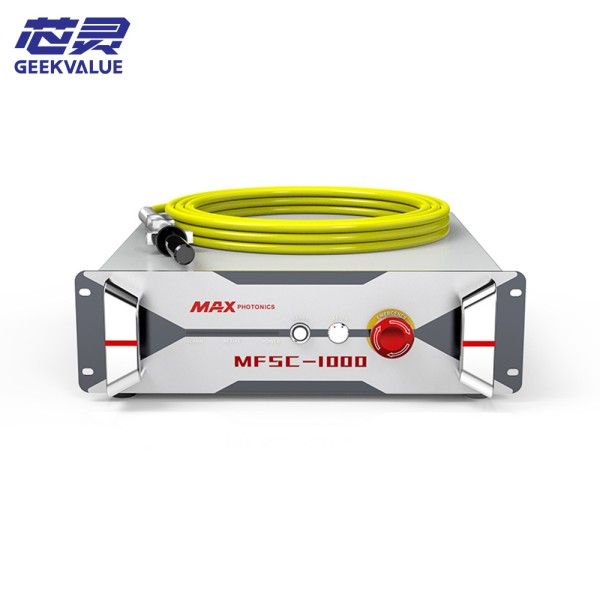

MFSC-1000 waa 1000W laser fiber joogto ah (CW). Mabda'a asaasiga ah wuxuu ku salaysan yahay tignoolajiyada laser fiber, iyo wax soo saarka awoodda sare waxaa lagu gaaraa iyada oo loo marayo xoojinta indhaha ee heerar badan:

Kicinta isha bamka

U isticmaal koronto-dhaliyaha laser diode (LD) oo ah isha matoorka si aad u sii dayso iftiinka hirarka 808nm ama 915nm.

Kordhinta fiber-ka doped

Iftiinka bamka wuxuu ku lammaan yahay ytterbium-doped (Yb³⁺) fiber, iyo ion-yada dhifka ah ee dhulku waxay nuugaan tamar si ay u dhaliyaan 1064 ~ 1080nm leysarka infrared-ka dhow.

Gawracashada godka resonant

Godka resonant waxaa sameeyay fiber Bragg grating (FBG), kaas oo doorta mowjadaha dhererka gaar ah oo xoojiya laysarka.

Soo saarista iftiinka

Ugu dambeyntii, waxaa la soo saaray iyada oo loo marayo fibre gudbinta (dhexroor xudunta 50 ~ 100μm), iyo barta cufnaanta tamarta sare ayaa la sameeyay ka dib markii diiradda.

2. Hawlaha muhiimka ah

Xaqiijinta Farsamada Shaqada Dhacdooyinka Codsiga

Wax soo saar joogto ah oo awood sare leh 1000W wax soo saar deggan, awood la hagaajin karo (30% ~ 100%) Goynta saxan qaro weyn oo bir ah (birta kaarboon ≤12mm)

Beam tayo sare leh M²≤1.2 (ku dhow hal qaab), meel yar oo diirada la saaray (dhexroor qiyaastii 0.1mm) Alxanka saxda ah (tabaha baytariyada, qaybaha elektarooniga ah)

Walxaha ka-hortagga sare-u-qaadista hagaajinta naqshadaynta indhaha si loo yareeyo soo noqoshada dhaawaca iftiinka inta lagu jiro farsamaynta walxaha aadka u milicsada sida naxaasta iyo aluminium alxanka tamarta cusub (maxaasta iyo aluminiumka biraha aan la mid ahayn)

Xakamaynta caqliga leh Waxay taageertaa isgaadhsiinta RS485/MODBUS, la socodka wakhtiga dhabta ah ee awooda iyo heerkulka, qaylo dhaan aan caadi ahayn Is dhexgalka khadka wax soo saarka otomaatiga ah

Badbaadinta tamarta iyo waxtarka sare ee waxtarka beddelka elektaroonigga ah ≥35%, in ka badan 50% badbaadinta tamarta marka la barbar dhigo CO₂ laser wax soo saarka tirada badan

3. Tilmaamaha farsamada

Naqshad qaabaysan

Qaybaha muhiimka ah sida isha bamka iyo fiber-ka indhaha ayaa si dhakhso ah loogu beddeli karaa kharash yar oo dayactir ah.

Ilaalinta badan

Heerkulka ka badan, hadda, iyo soo celinta ilaalinta iftiinka si loo hubiyo nolosha qalabka (≥100,000 saacadood).

Waafaqid ballaaran

La qabsan kara noocyada kala duwan ee madaxyada farsamaynta (sida madax goynta, madax alxanka) iyo nidaamyada xakamaynta dhaqdhaqaaqa (CNC, gacmaha robotic).

IV. Kiisaska codsiga caadiga ah

Goynta birta: 6mm goynta xawaaraha sare ee birta ah (xawaaraha ≥8m/min).

Alxanka: alxanka busbar ee baytariyada korontada (spatter <3%).

Daawaynta dusha sare: nadiifinta caaryada laysarka (ka-saarida lakabka oksaydhka iyada oo aan waxyeelo lahayn substrate).

V. Isbarbardhigga faa'iidooyinka tartanka

Halbeegyada MFSC-1000 Caadiga ah 1000W laser

Tayada beam M²≤1.2 M²≤1.5

Hufnaanta Electro-optical ≥35% Caadiyan 25% ~ 30%

Xakamaynta interface RS485/MODBUS+analoogga tirada Analog Control tirada kaliya

Qiimaha dayactirka Naqshad qaabaysan, beddelaad fudud ayaa loo baahan yahay in lagu soo celiyo warshadda si loo dayactiro

VI. Soo jeedinta xulashada

Ku habboon: goynta saxan dhexdhexaad ah iyo qaro weyn, alxanka wax-soo-saarka sare leh, is-dhexgalka khadka wax-soo-saarka otomaatiga ah.

Xaalado aan la dabaqi karin: farsamaynta aadka u saxda ah (waxay u baahan tahay picosecond/femtosecond laser) ama goynta aan biraha ahayn (sida caag, alwaax)