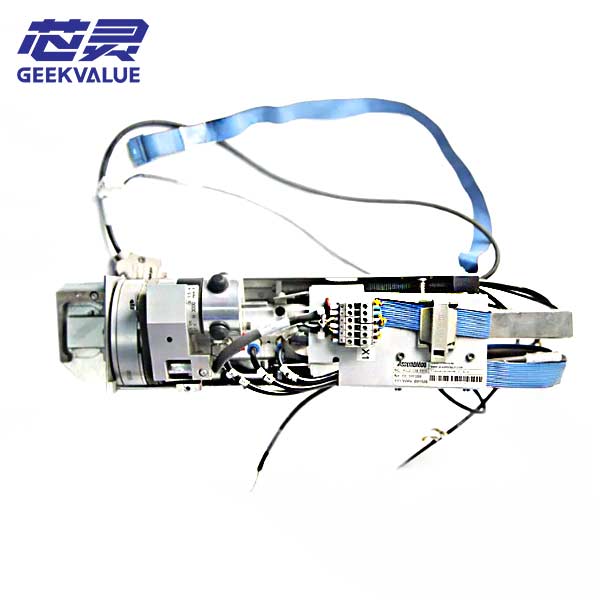

The Asbion SMT head is a key component used in SMT processing. It can automatically correct the position under the control of the correction system and accurately place the components in the specified position. The development of Asbion's head has undergone a transition from the early single-head mechanical centering to the multi-head optical centering, and the speed and accuracy of the placement have been continuously improved.

Types and characteristics

Fixed single head: The early single-head SMT machine achieved component centering through a mechanical centering mechanism, but the placement speed was slow. In order to increase the speed, the number of heads is usually increased.

Fixed multi-head: On the basis of the fixed single head, it is increased to 3 to 6 heads, using optical centering, the placement speed can reach 30,000 components/hour, and the price is low, which is suitable for combined use.

Combined head: For example, the Asbion FCM SMT machine consists of 16 independent heads, each head can only place 6,000 components per hour, but through a balanced combination, extremely high placement speed and accuracy can be achieved. Technical parameters and performance

The technical parameters and performance of the Asbion chip head vary in different models and configurations. For example, the AX series equipment has a production capacity of 45k to 150k cph, which is suitable for fast equipment changeover in high-frequency mixed environments. This series of equipment has a small footprint, has the advantage of parallel placement, and has a repeat positioning accuracy of 50 microns. In addition, Asbion also demonstrated the AQ-2 ultra-fine pitch and special-shaped parts placement machine, which is suitable for the placement of ultra-fine pitch and special-shaped components, with a production output of up to 3.1k cph.

In summary, Asbion chip heads perform well in SMT processing with their high efficiency, flexibility and precision, and are suitable for various production needs and environments.