Working Principle

The IC work head of the ASM placement machine picks up components through a suction nozzle controlled by a vacuum pump. The suction nozzle uses negative pressure to suck components from the feeder, and realizes high-precision placement operations through sensor recognition and control system algorithms. When the suction nozzle sucks and places components, it needs to reach a certain negative pressure to ensure that the components can be picked up and placed correctly.

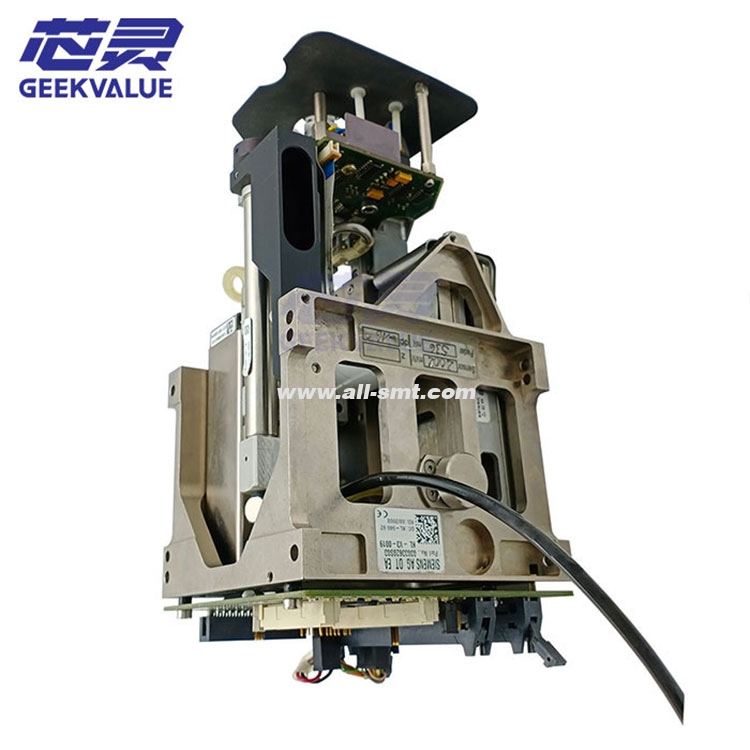

Components and their functions

The IC work head is mainly composed of the following parts:

Nozzle: used to suck components. Components of different shapes and sizes require suction nozzles of different shapes. The suction nozzle picks up components by generating negative pressure through vacuum, and controls the placement process through pressure sensors.

Visual recognition system: used to identify and locate components to ensure the accuracy of placement.

Positioning system: through mechanical or optical alignment systems, ensure the accurate position of components during the placement process.

Sensor: including pressure sensors, negative pressure sensors, etc., used to monitor and control various parameters in the placement process to ensure the stability and accuracy of operation. Maintenance and care methods

In order to ensure the normal operation of the IC work head, regular maintenance and care are required:

Clean the suction nozzle: Clean the suction nozzle regularly to prevent clogging and wear.

Check the sensor: Ensure that the pressure sensor and negative pressure sensor are working properly, and replace the damaged sensor in time.

Check the vacuum system: Check the vacuum generator and vacuum hose regularly to ensure the normal operation of the vacuum system.

Calibrate the positioning system: Calibrate the positioning system regularly to ensure the accuracy of the placement.

Through the above maintenance and care measures, the service life of the IC work head can be extended and the overall performance and stability of the placement machine can be improved.

We also supply following Siemens Spare parts :

| 00341780-02 | DP Motor | 03058627-02 | CP20A DP Motor |

| 03102532-01 | CP20P DP Motor | 03050314S03 | CPP DP Motro |

| 03072785S01 | CP20A Generator | 03106620S01 | CP20P Generator |

| 03152828S01 | CPP Generator | 03055438-01 | CPP Generator |

| 03058802-02 | TH Generator | 03038908S01 | Z-axis Motor |

| 03058631-02 | CP20A Z-axis Motor | 03061102S01 | CP Z-axis Motor |

| 03005123S01 | CP20A Distributor | 03081381-01 | CPP Distributor |

| 03058629-01 | CP20A Round Plate control unit | 03115167-01 | CPP Disc control unit |

| 03003426S02 | Camera 23 Component | 03054153-04 | 2003 Nozzle |

| 03013307-01 | 1001Nozzle | 03057850S03 | 2007 Nozzle |

| 03054923-03 | 2033 Nozzle | 03059921S03 | 2038 Nozzle |

| 03083001S03 | CP20A Component Sensor | 03037106-01 | CPP Component Sensor |

| 03092400-02 | CP20P Sensor | 03133310-01 | P2 Sensor |

| 03039099-01 | CPP Sliding block | 03060811-01 | TSP 400 track board |

| 03087642-01 | TSP 420 Track board | 03055072-01 | Head Board |

| 03054790S01 | CPP SCS Control Card | 03115454-01 | Image Card |

| 03057377S02 | WPC Control Card | 03037845-01 | CP20A Round Holder |

| 03091256-01 | X-axis grading scale | 03091255-02 | Y-axis grading scale |

| 03092666-02 | Track Solenoid valve | 03092667S03 | Track Solenoid valve |

| 03059084-01 | Y-axis Sliding block | 03109668-01 | HCU |

| 03052200-01 | GCU Computer | 03059666-01 | FCU |

| 03059623-01 | FCU | 03079685-02 | Ring RACE |

| 03002942-01 | Shield Card | 03083835-01 | New mode DP Motor |

Our Advantages:

We have strict inspection standards for the quality of our products, which has formed a high-standard process system;

We have a strong price advantage, absolute price advantage is the best choice for customers;

our business philosophy: "Customer first, Quality first " Principle;

We are a big international brand level agents and over the years we accumulated a high quality customer resources;

We have a global sourcing, huge demand we can reduce the purchase cost. More new accessories supply to ensure our sustainable supply and price advantage.

Successful Experience:

Xlin's customer in 30 countries around the world

We have been helping customers to build a lot of new factories around the world.

We hope Became the most reliable Chinese partner for you.