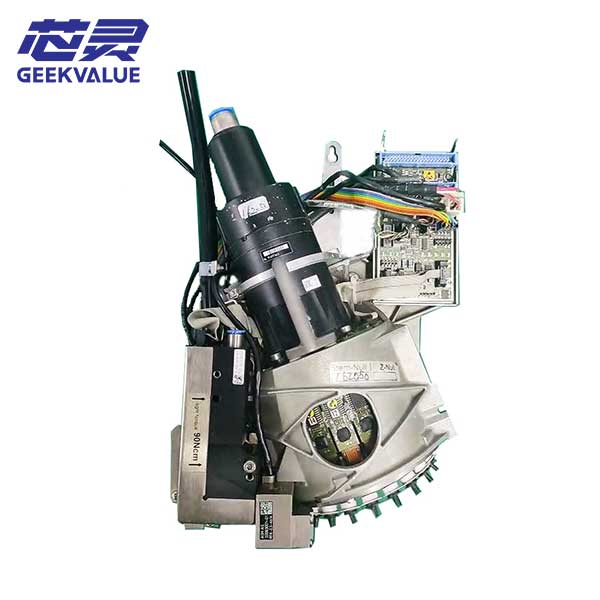

CP20A patch head is an important component in Siemens patch machine, mainly used for high-speed patch operation.

Working principle of vacuum generator

The vacuum generator of CP20A patch head uses the principle of Venturi tube to generate vacuum. When compressed air enters the Venturi tube through the air inlet, the airflow changes from coarse to fine and the flow rate increases, thus forming a "vacuum" area at the outlet of the Venturi tube. This vacuum area will produce adsorption when it is close to the workpiece, adsorbing the workpiece to complete the patch operation.

Common faults and maintenance methods

Common faults of CP20A patch head DP motor include software disabling, bottom light barrier, vacuum error, zero point error, cable breakage, patch offset and other problems. These faults are usually caused by accessory loss or improper operation. To solve these problems, the following measures can be taken: Software disabling: Check the software settings to ensure that all functions are enabled normally. Bottom light barrier: Check whether the light barrier sensor is blocked or damaged. Vacuum error: Check whether the vacuum system is working properly and replace the vacuum pump or vacuum generator if necessary. Zero point is incorrect: Recalibrate the patch head to ensure that the zero point is set correctly.

Wire break: Check and repair the wiring problem.

Patch offset: Adjust the position and parameters of the patch head to ensure patch accuracy.

Maintenance and care methods

In order to extend the service life of the CP20A patch head and ensure its stable operation, the following maintenance and care are recommended:

Regular cleaning: Clean the patch head and vacuum system regularly to prevent dust and impurities from affecting the working effect.

Check the sensor: Check the working status of the sensor regularly to ensure its sensitivity and accuracy.

Calibration: Calibrate the position and parameters of the patch head regularly to ensure the accuracy and stability of the patch.

Replace worn parts: Replace worn parts such as vacuum pumps, venturi tubes, etc. in a timely manner.

Through the above introduction, you can better understand and use the CP20A patch head to ensure its efficient and stable operation