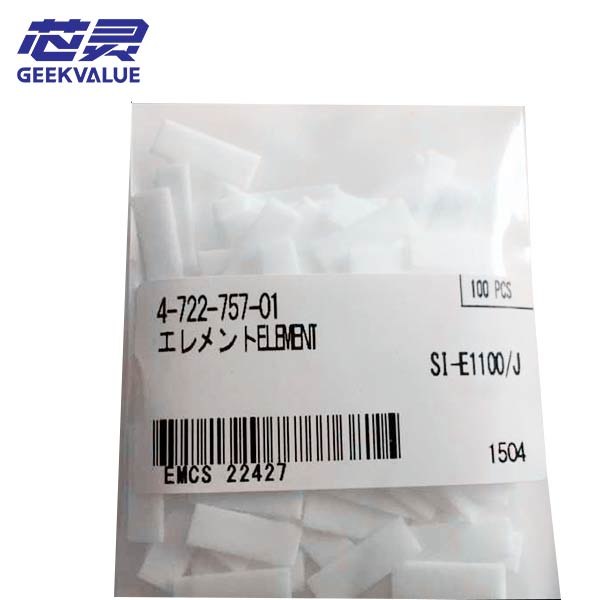

The main function of the Sony SMT filter cotton is to filter the oil and moisture in the compressed air to prevent these impurities from entering the equipment, thereby extending the service life of the equipment and improving production efficiency. Specifically, the filter cotton can filter out the oil and moisture in the compressed air, avoid damage to the equipment by these foreign objects, and thus protect the normal operation of the equipment.

Working principle of filter cotton

The working principle of filter cotton is to intercept impurities such as oil and moisture in the air through physical barriers to ensure that the air entering the equipment is purer. This can reduce equipment failures caused by inhaling impurities and extend the service life of the equipment.

Maintenance and replacement methods

For the maintenance and replacement of filter cotton, it is recommended to check the status of the filter cotton regularly. Once the filter cotton is found to be contaminated or blocked, it should be replaced in time. When replacing, filter cotton that matches the equipment model should be selected to ensure its filtering effect and compatibility. In addition, regular cleaning of the surface of the filter cotton can extend its service life.

Through the above measures, the normal operation of the Sony SMT machine can be ensured, production efficiency can be improved, and equipment failures caused by air impurities can be reduced.