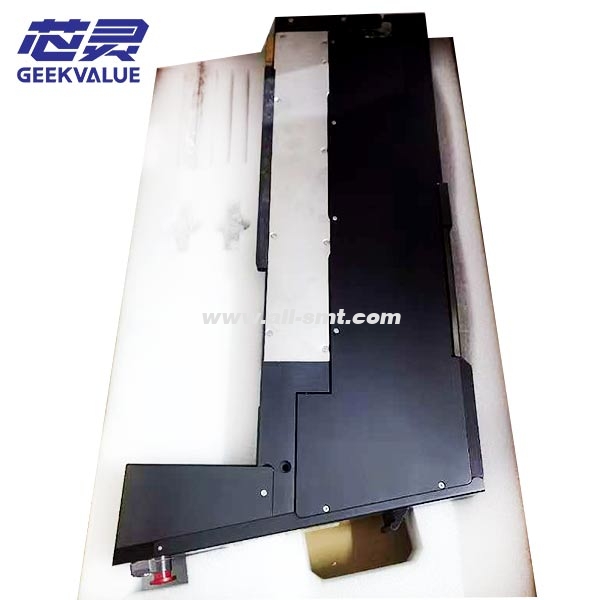

ASM SIPLACE POP Feeder is a feeder designed for surface mount technology (SMT) applications, especially for chip placement needs in system-level package (SiP) production. The following is a comprehensive introduction to the ASM SIPLACE POP Feeder:

Basic functions and features

The main function of the ASM SIPLACE POP Feeder is to provide high-quality chip and component feeding for SMT production lines. Its features include:

High precision: It can ensure accurate feeding of components to meet the needs of high-precision placement.

Efficiency: Designed for high-speed production, it can handle a large number of components and improve production efficiency.

Flexibility: Suitable for a variety of component types, including chips and system-level package components.

Reliability: Stable performance and durable design ensure long-term stable operation.

Technical specifications and performance parameters

The technical specifications and performance parameters of the ASM SIPLACE POP Feeder include:

Feeding speed: It can handle up to 50,000 chips or 76,000 surface mount components (SMD) per hour with an accuracy of up to 10 μm @ 3 σ.

Compatibility: Suitable for chips cut directly from wafers, as well as flip chips and passive components from reel tapes.

Integration capability: Able to seamlessly integrate with existing SMT production lines to provide comprehensive automation solutions.

Application scenarios and market positioning

ASM SIPLACE POP Feeder is widely used in the production of various electronic products, especially in applications requiring high-density and high-precision assembly. Its market positioning is for high-end electronic manufacturing service (EMS) providers and original equipment manufacturers (OEMs), especially in the fields of automobiles, 5G/6G communications, smart devices, etc..