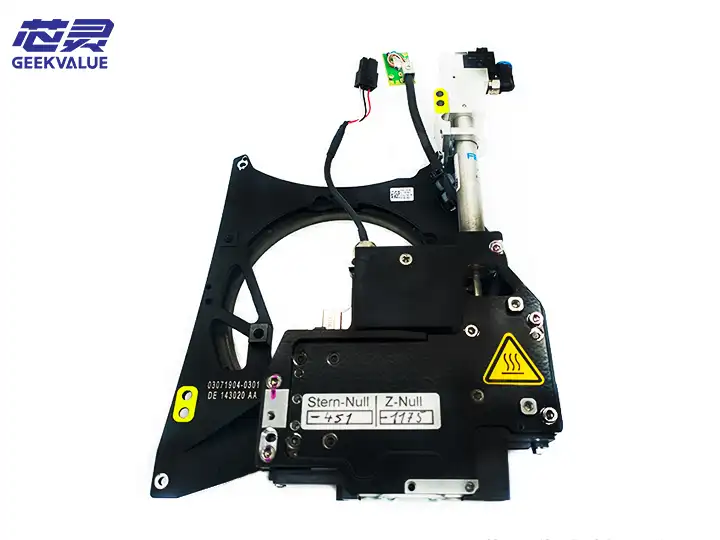

Siemens SMT 12/16MM S feeder is a feeder in the Siemens SMT series, which is mainly used in the SMT (surface mount technology) production process to provide SMD (surface mount components) to the SMT machine for SMT operation. The following is a comprehensive introduction to the Siemens 12/16MM S feeder:

Basic information

The width of the Siemens 12/16MM S feeder is 12mm and 16mm, which is suitable for SMD components of different sizes. The design of this feeder makes it more flexible and efficient when handling components of different package sizes.

Working principle

The working principle of the Siemens feeder includes the following steps:

Component loading: The feeder is equipped with multiple trays, each of which is loaded with different types of components.

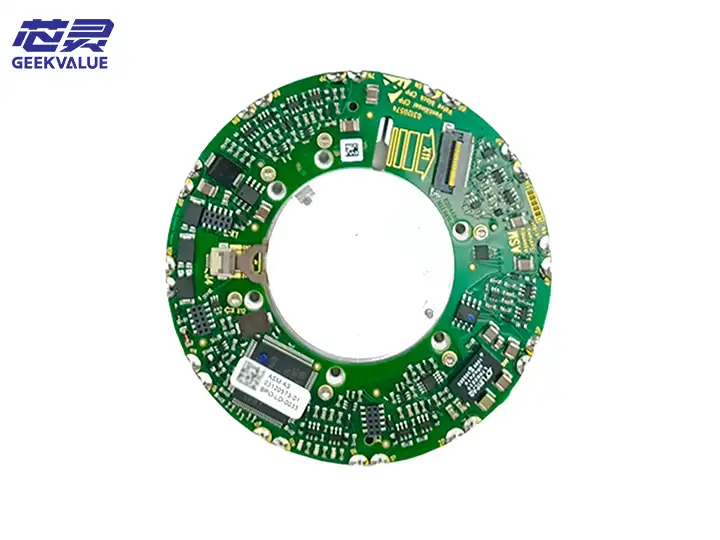

Grasping and positioning: The feeder is driven by a high-precision servo motor, grabs components through vacuum adsorption technology, and detects the position and status of components through sensors to ensure accurate grabbing.

Placement: After the feeder accurately positions the components on the PCB board, it releases the vacuum and places the components on the preset position. This process requires the cooperation of the visual system of the placement machine to achieve high-precision placement.

Application scenarios

Siemens 12/16MM S feeder is widely used in SMT production and is suitable for the assembly needs of various electronic products. Its high precision and stability make it perform well in high-quality production environments.

Maintenance and maintenance

In order to ensure the long-term stable operation of the Siemens feeder, regular maintenance and maintenance are required:

Cleaning: Prevent dust and residue from affecting performance.

Inspection: Check the wear of each component and replace the worn parts in time.

Lubrication: Maintain lubrication to avoid equipment failure caused by excessive friction.

Through the above introduction, you can better understand the functions, applications and maintenance methods of Siemens 12/16MM S feeder, so as to maximize its effectiveness in SMT production.