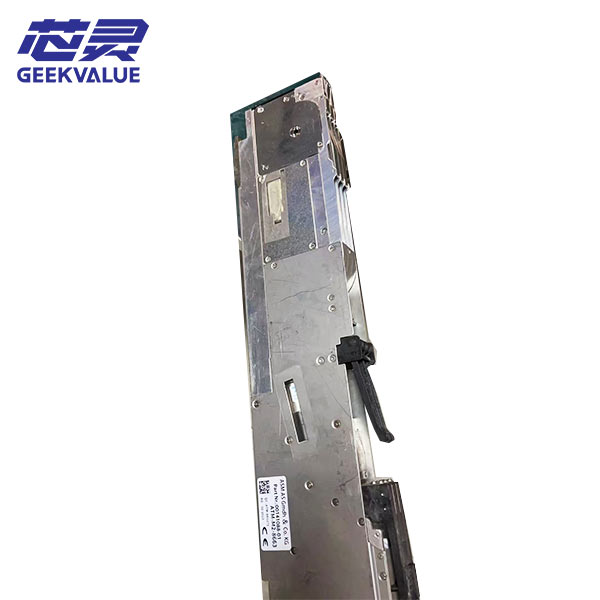

Siemens SMT 3x8sl Feeder is one of the Siemens SMT series, mainly used in SMT (surface mount technology) production lines, responsible for providing SMD (surface mount components) to the SMT machine for SMT operations. The main function of the feeder is to provide the SMD SMT components installed on the feeder to the SMT machine for SMT, ensuring the smooth operation of the production line.

Types and specifications of feeders

There are mainly the following types of Siemens SMT feeders:

Box feeder: suitable for small batch production, easy to replace and maintain.

Belt feeder: suitable for medium batch production, stable feeding, suitable for a variety of materials.

Tube feeder: suitable for long strip components, such as resistors, capacitors, etc.

Tray feeder: suitable for large-scale production, high degree of automation, suitable for high-efficiency production.

The specifications of Siemens SMT 3x8sl feeder mainly include:

Width: Common widths are 4mm, 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 72mm, etc. The width of Siemens SMT feeder is a multiple of 4, mainly because the distance between the two vertices of the outer ring of the feeder gear and the hole spacing of the material strip are both 4mm.

Price and configuration quantity

The price of Siemens SMT feeder varies depending on the degree of newness. The price of second-hand feeder is relatively low and suitable for users with limited budget. The price of new feeder will be higher, but the performance is more reliable.

In terms of the number of configurations, it needs to be determined according to the production needs of the factory. Too many configurations will lead to waste of resources and increased costs, and too few configurations may affect production efficiency. Therefore, it is necessary to make reasonable configurations based on factors such as the proportion of materials at each spacing, material change frequency, and material preparation to reduce waiting time and improve production efficiency. Applicable scenarios and advantages

The Siemens SMT feeder 3x8sl is suitable for the production of various electronic products, such as mobile phones, computers, home appliances, etc. Its advantages include:

High precision: The SMT precision is high, suitable for the production of electronic products with high precision requirements.

High efficiency: The feeding speed is fast, suitable for large-scale production.

Stability: The smart feeder feeds more stably and reduces the failure rate in production.

In summary, the Siemens SMT feeder 3x8sl plays an important role in the SMT production line. Through reasonable configuration and use, it can effectively improve production efficiency and product quality.