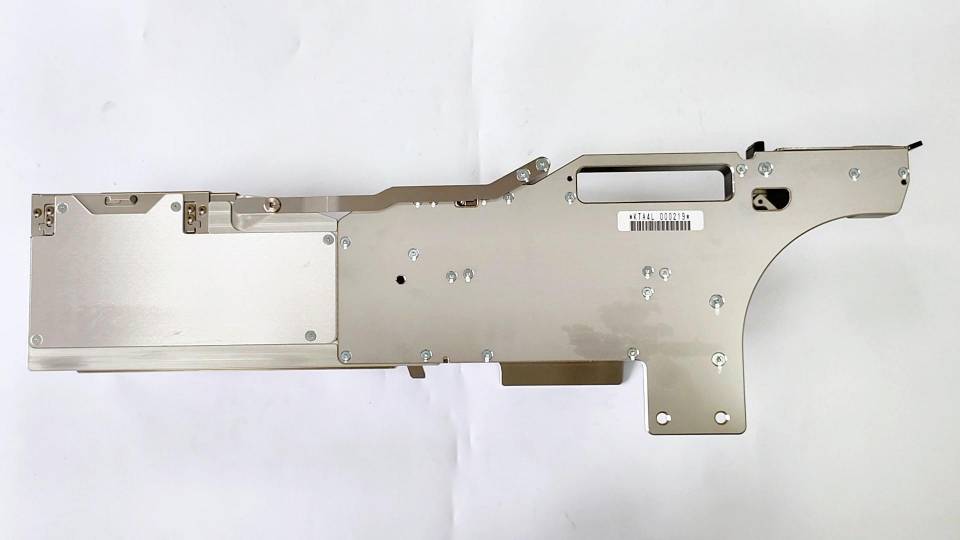

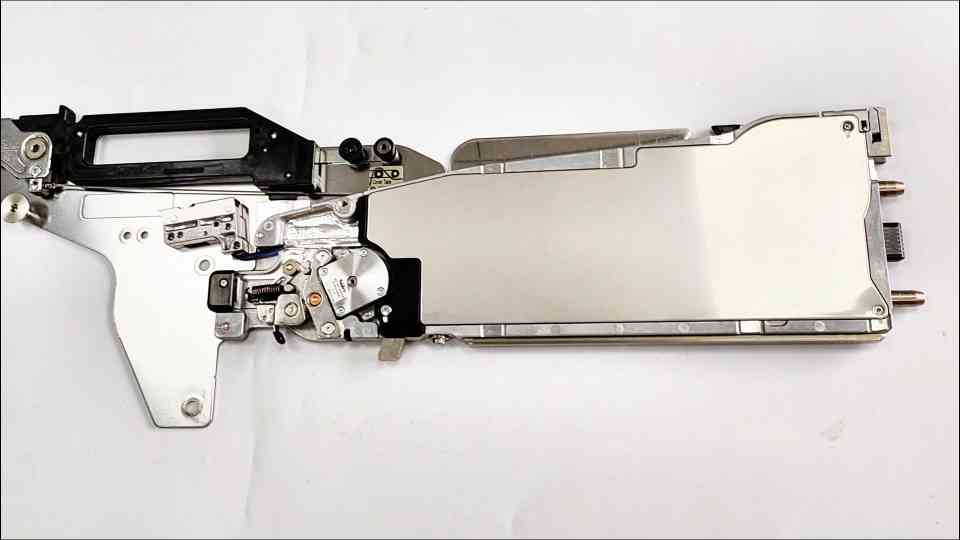

The main functions and effects of the Fuji SMT machine 8MM feeder include:

Component delivery and positioning: The 8MM feeder is an important part of the SMT machine, which is mainly used to take components out of the material tray and place them accurately on the PCB board. Its working principle is to drive the slider to move at a certain speed through the motor, clamp or absorb the components, and then place them on the PCB board according to the preset position.

Improve production efficiency and precision: The calibration of the feeder directly affects the precision and production efficiency of the SMT machine. Regular calibration of the feeder can ensure that the components are picked up and mounted in the correct position, reduce the downtime and error rate of the SMT machine, and thus improve production efficiency. Reduce failures and extend equipment life: Regular calibration of the feeder can reduce mechanical wear, detect and correct problems in time, prevent equipment damage, and thus extend the service life of the equipment. Reduce production costs: Through feeder calibration, the scrap rate and rework times can be reduced, ensuring that each component can be mounted correctly, reducing material waste, and thus reducing production costs. Maintenance and calibration methods

In order to keep the normal operation of the feeder, regular maintenance and calibration are required:

Regular cleaning: Clean the feeder to prevent dust from accumulating on the slider, feeder fixture and other parts, affecting the accuracy.

Regular refueling: Lubricate the key parts of the feeder to prevent increased friction from causing decreased accuracy and increased noise.

Regularly replace the air source filter: Ensure that the air source does not contain moisture and impurities to ensure the adsorption effect of the nozzle.

Regular inspection of parts: Check whether the parts of the feeder are damaged or loose to ensure their normal operation.

Visual system calibration: Adjust the position and focal length through the camera, determine the reference point position of the feeder, and perform automatic calibration.

Mechanical calibration: Check whether the mechanical parts of the feeder are normal, use standard reference tools to measure the position and angle, and adjust the fixing bolts.

Software calibration: Install and run the matching calibration software, enter the corresponding calibration parameters, perform automatic calibration and verify the results.

Through these maintenance and calibration measures, the normal operation and efficient work of the 8MM feeder can be ensured.