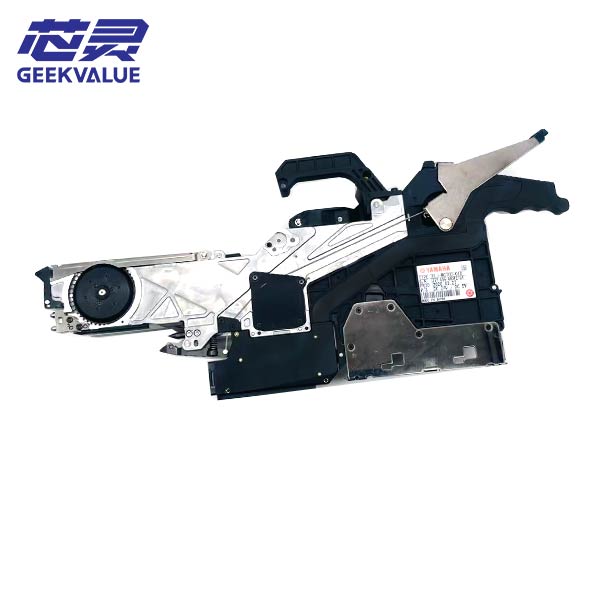

The main function of the Yamaha 56MM SMT feeder is to provide electronic components to the SMT machine for automatic placement. The feeder picks up electronic components from the tape or tray and places them on the circuit board through its robotic arm and nozzle system, thereby realizing the automated placement process.

Working principle of the feeder

The working principle of the feeder is based on the vacuum nozzle system. The robotic arm picks up the components through the nozzle and then places them on the circuit board. For components of different sizes, the size and shape of the nozzle will vary to ensure accurate pickup and placement.

Scope of application of the feeder

The feeder is suitable for components of various sizes, including chips, connectors, etc. For small-sized components, such as 0201 packages, a smaller nozzle is required to ensure accurate pickup and placement.

Advantages and disadvantages of the feeder

Advantages:

High precision: The electric feeder transmits and feeds materials through an electronic electromagnetic drive motor, with high precision, which is suitable for the placement of small-sized components.

Wide scope: Suitable for components of various sizes, including chips, connectors, etc.

Easy to operate: Once the working mode is set, the equipment can work automatically without manual intervention, which improves the accuracy of operation.

Disadvantages:

High cost: The electric feeder equipment and technology are relatively complex and costly.

High maintenance requirements: Regular maintenance and care are required to ensure the stable operation of the equipment.

In summary, the Yamaha SMT 56MM feeder plays an important role in electronic manufacturing, which can improve production efficiency and placement accuracy, but it also requires high maintenance costs and technical support.