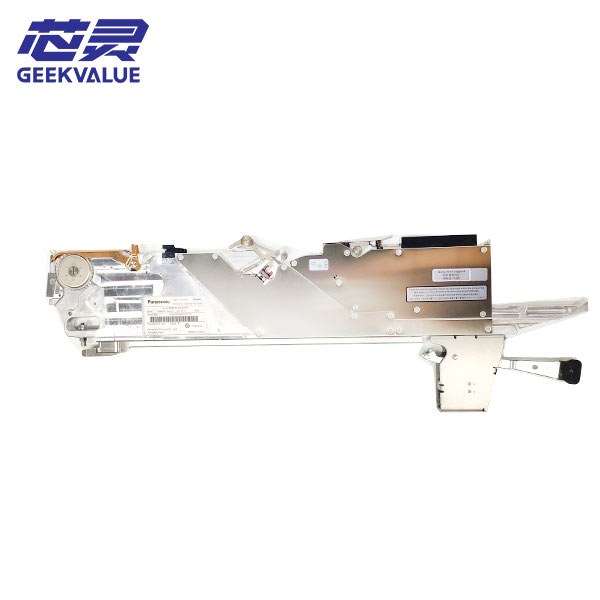

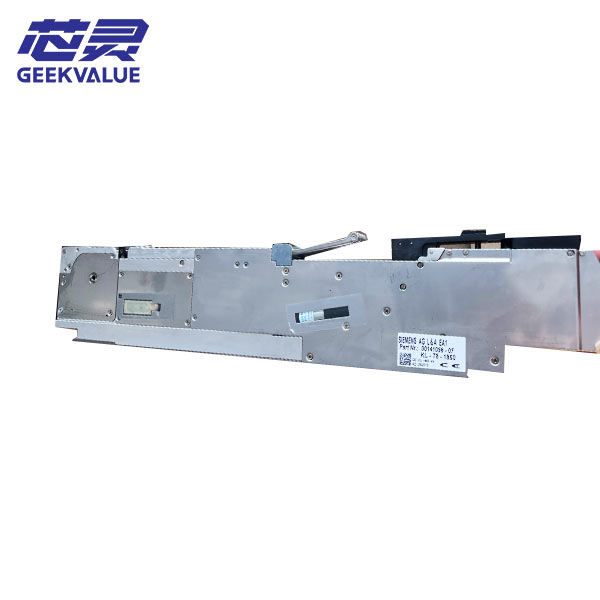

Panasonic SMT NPM 8MM Feeder is a SMT machine accessory provided by Panasonic Electric Mechatronics (China) Co., Ltd., mainly used in SMT (surface mount technology) production lines. The feeder is suitable for 0201-size components and has high mounting accuracy and production efficiency.

Specifications and functions of the feeder

Component size: Suitable for 0201-size components.

Mounting speed: 0.106 seconds/chip.

Mounting accuracy: 40 microns/chip.

Corresponding component size: Components from 0402 to 100*90mm.

Functions and effects

Automatic feeding: NPM 8MM feeder can automatically feed on the SMT production line to ensure that the SMT machine is continuously fed during high-speed and high-precision production, improving production efficiency and product quality.

Adapt to a variety of application scenarios: NPM 8MM feeder is suitable for components of various sizes, such as 8mm, 12mm, 16mm, etc., to meet different production needs.

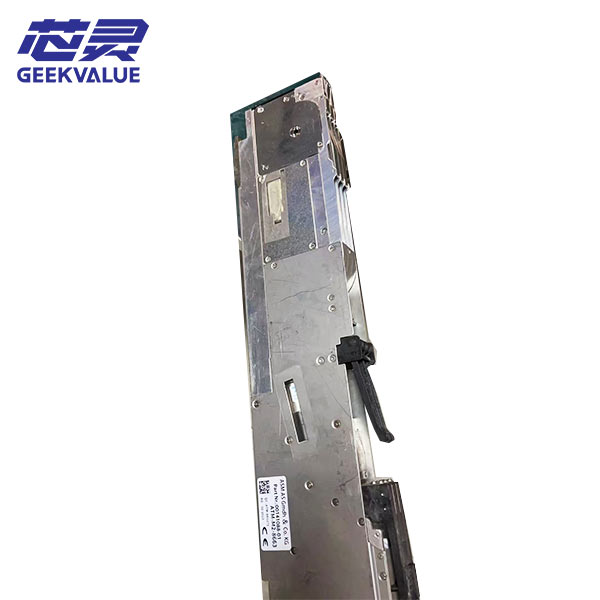

Maintenance and servicing: The feeder requires regular maintenance and servicing to ensure its long-term stable operation. High productivity: Through the dual-track mounting method, when connecting 3 NPMs, the mounting speed is as high as 171,000cph, and the unit area productivity is 27,800cph/rf. High functionality and high reliability: Fully compatible with CM Series hardware, it can correspond to components from 0402 to 100*90mm, and has functions such as component thickness inspection and substrate bending inspection, which is suitable for high-difficulty process requirements. Humanized design: With a humanized interface design, the machine model switching indication can greatly shorten the exchange operation time of the material rack trolley. These features make Panasonic NPM series placement machines perform well in production efficiency and mounting quality, and are suitable for various high-demand SMT production lines. Scope of application NPM 8MM feeder is widely used in the electronics manufacturing industry, especially in SMT production lines, for automatic feeding, improving production efficiency and product quality. Maintenance and care methods

Regular cleaning: Keep the feeder clean to avoid dust and impurities affecting the feeding effect.

Check the sensor: Check the working status of the sensor regularly to ensure that it accurately detects the components.

Lubrication: Properly lubricate the mechanical part of the feeder to reduce friction and extend its service life.

Through the above measures, it can ensure that the NPM 8MM feeder can perform at its best in SMT production, improve production efficiency and product quality.