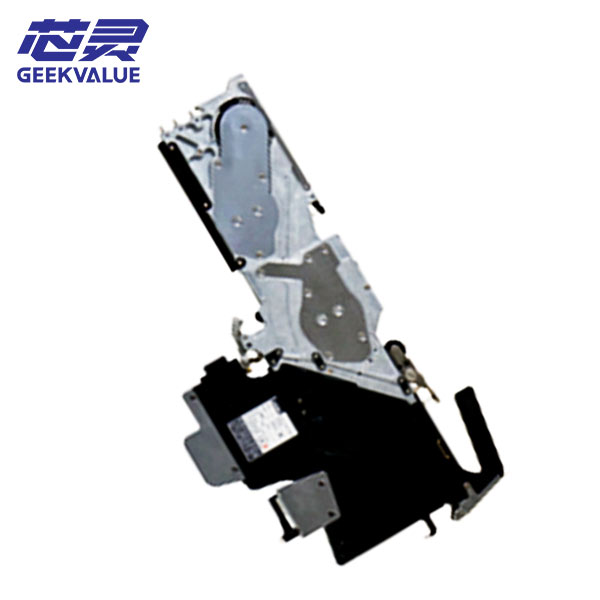

The main function of the 16MM feeder of the JUKI SMT machine is to provide the feeding of 16MM components, which is suitable for the supply of components in the SMT patch production process.

Basic functions

Component feeding: The 16MM feeder is mainly used to provide 16MM size components to ensure that the SMT machine has sufficient component supply during the patch process.

High precision: The JUKI electric feeder has the characteristics of high precision and high stability, which can ensure the accurate supply and placement of components.

Wide range of application: Suitable for the feeding of a variety of electronic components and suitable for different patch requirements.

Usage scenarios

Automated production: On the automated production line, the 16MM feeder can be connected to the SMT machine, and through signal transmission and mechanical movement synchronization, it ensures the accurate supply and placement of components.

Multiple drive modes: The feeder can be divided into electric drive, pneumatic drive and mechanical drive according to different drive modes, which are suitable for electronic components of different sizes, shapes and packaging methods.

Operation and maintenance

Component identification and positioning: The feeder uses internal sensors or cameras to identify the type, size, pin direction and other information of the component to ensure accurate picking and placement of the component.

Maintenance: Regularly check the sensors, electromagnetic coils and other components of the feeder to ensure their normal operation and avoid failures that affect production efficiency.

Through the introduction of the above functions and usage scenarios, you can better understand the important role of the JUKI SMT machine 16MM feeder in SMT patch production.