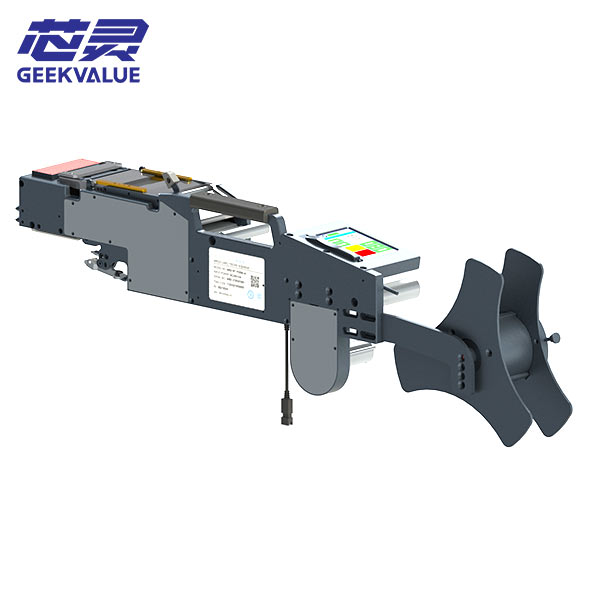

Yamaha label feeder has the following advantages:

No need to purchase labeling machine separately, barcode label can be attached with label feeder;

Strong compatibility of material types: label feeder can be used for paper labels, FPC reinforcing steel sheets, various Mylar tapes, foams, dustproof nets, high-temperature tapes and other roll materials;

Strong compatibility of material size: one label feeder can handle all materials within the maximum size, and supports single or multiple rows, maximizing the use efficiency of the machine;

The flap design of the stripping plate can achieve the fastest material change, and the vacuum hole adsorption can steadily increase the tension of the material belt, which is convenient for the successful stripping of sticky materials; the sliding rib allows one feeder to meet the use of more width materials; the machine screws around the magnetic pressure cover can adjust the height gap to meet the smooth passage of materials of different thicknesses.

The fine-hole fiber optic material receiving platform has a smoother surface than the strip slot receiving platform. Highly anti-sticky silicone pads ensure that both adhesive tape and foam can be easily absorbed, and are easy to replace and have low maintenance costs; multi-head ultra-sensitive fiber optic sensors can meet the requirements of single-row to multi-row (up to 12 rows) labels with different gaps for simultaneous stripping; the upper and lower lifting slide design can easily and accurately set the height of the receiving platform to adapt to the successful stripping of materials of different thicknesses.

The feeding method of super wear-resistant rubber-coated wheels with gears not only solves the problem of feeding errors caused by slipping of the bottom paper, but also solves the problem of easy damage to the rubber-coated wheels; the bevel locking design and increased contact area between the bottom paper and the gears make it easy to open and ensure safe and effective locking.

The standard inner diameter 76.2mm (3 inches) and outer diameter 220mm hanging material mechanical tensioning shaft are convenient for loading and unloading and effective clamping; the optional inner diameter 152mm (6 inches) tensioning shaft assembly can meet the requirements of multi-size inner diameter roll labels; the material discharge box structure can also be selected.