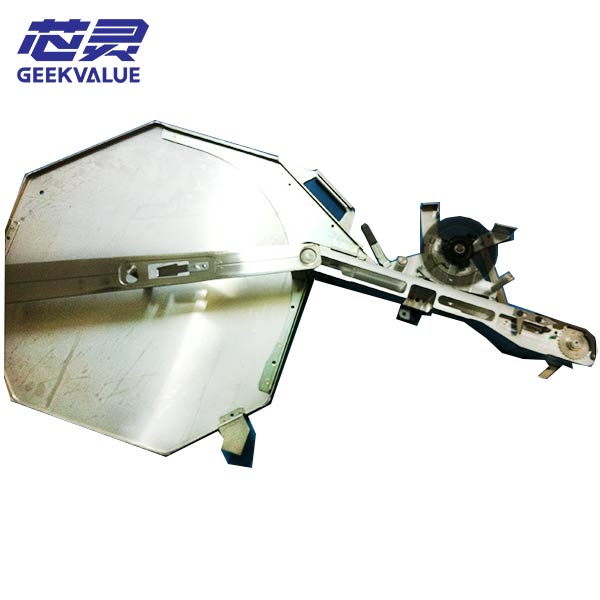

Sony SMT feeder is an important part of Sony SMT machine, used for automatic feeding in the SMT (surface mount technology) production process. The main function of the feeder is to mount the SMD (surface mount components) on the feeder for the SMT machine, so as to achieve efficient and accurate component placement.

Types and specifications

Sony SMT feeders have many types, mainly including the following:

Tape feeder: This is the most commonly used feeder type, with a variety of specifications such as 8mm, 12mm, 16mm, 24mm, 32mm, 44mm and 52mm. The strip spacing has a variety of options such as 2mm, 4mm, 8mm, 12mm and 16mm, and the material can be paper or plastic. Tube feeder: Suitable for components such as PLCC and SOIC, it has the characteristics of good protection of component pins, but poor stability and standardization, and low production efficiency.

Box feeder: Also known as a vibrating feeder, it is suitable for non-polar rectangular and cylindrical components, but not for polar components and small-profile semiconductor components.

Tray feeder: It is divided into single-layer and multi-layer structures, suitable for IC integrated circuit components, with small footprint and compact structure.

Application scenarios and advantages

Sony chip mounter feeders are widely used in SMT production lines, which can significantly improve production efficiency and mounting accuracy. The belt feeder has higher transmission accuracy, faster feeding speed and more stable performance due to its high-precision electric design, which greatly improves production efficiency. The tube feeder has better protection for component pins, but poor stability and standardization, and low production efficiency. Box feeders and tray feeders are suitable for specific component types and production needs.

In summary, Sony chip mounter feeders play a key role in SMT production. By choosing different types of feeders, different production needs can be met to ensure efficient and stable patch operations.