The main function of the SMT solder wire feeder is to fix the SMD components on the PCB board to ensure the precise positioning and high-quality installation of the components. Specific functions include:

Precise positioning: The solder wire feeder can ensure the precise position of the components on the PCB board, reduce deviations, and improve mounting accuracy.

High-precision installation: Through the intelligent control system, the solder wire feeder can achieve high-precision component installation and ensure mounting quality.

High-speed positioning: The design of the feeder enables it to work stably in a high-speed production environment and improve production efficiency.

High-precision grasping: The mechanical structure and control system of the feeder can ensure the accurate grasping and placement of components.

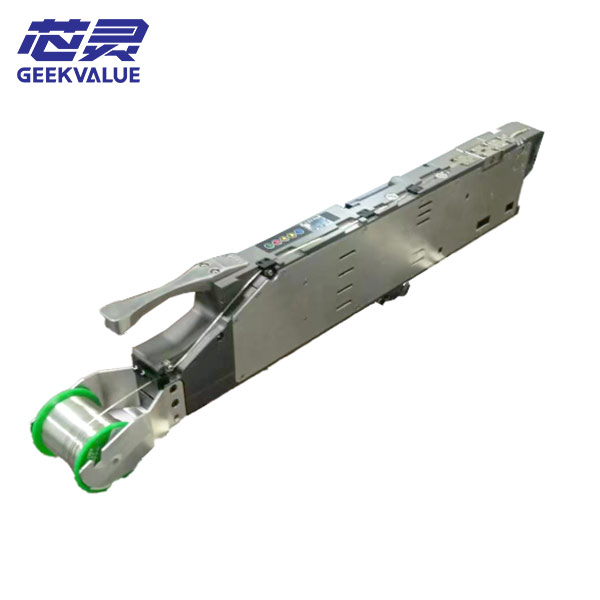

Structural composition

The structure of the solder wire feeder is mainly composed of the following parts:

Mechanical structure: Including feeder head, feeder robot arm, feeder motor, feeder positioning seat, etc.

Electrical control: Mainly composed of the placement machine control board, transmission device, reducer, driver, track power supply and other control electrical appliances and cables.

Software control: Precise control is achieved through the placement machine control program.

Maintenance and care methods

In order to ensure the long-term stable operation of the solder wire feeder, regular maintenance and care are required:

Regular cleaning: Clean the feeder head, robotic arm and other parts to prevent dust and impurities from affecting the accuracy.

Regular inspection: Check the tightness of electrical connections and mechanical parts to ensure a firm connection.

Regular replacement of parts: Replace worn parts such as motors and positioning seats to ensure the normal operation of the equipment.

Regular calibration: Calibrate the feeder to ensure the accuracy of positioning and grasping