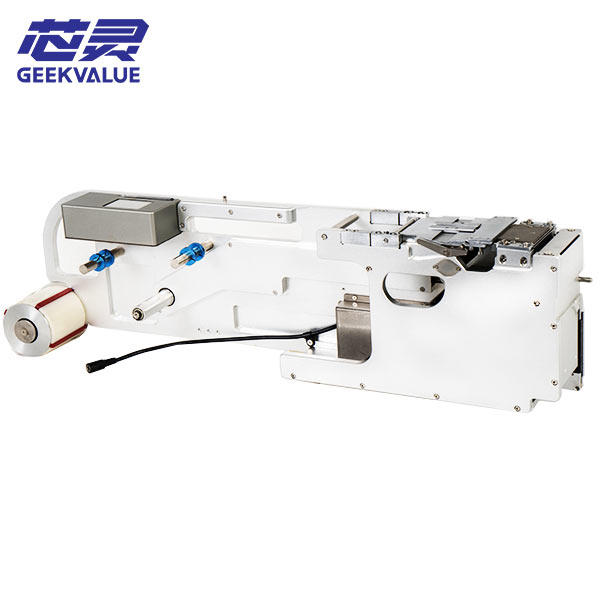

ASM SMT label feeder is a device specially used for handling and installing electronic components, usually used in conjunction with a SMT machine. It is one of the important accessories of the SMT machine, mainly used for mass production on automated production lines, aiming to improve the efficiency of SMT production and ensure the quality of SMT products.

Definition and function

The label feeder is essentially a nozzle, which picks up components from the component library according to program control, and accurately transports them to the appropriate position, and then places the components on the PCB board through the nozzle. Due to the different sizes, shapes and weights of various components, the label feeder needs to be used in conjunction with nozzles of various specifications to achieve accurate handling.

Usage and maintenance

Check the processed materials: Make sure the materials meet the requirements and are not damaged or deformed.

Choose a suitable tape feeder: Choose a suitable tape feeder type according to the width of the tape, such as 8mm2P, 8mm4P, etc.. Install the feeder: Open the feeder, pass the braid through the feeder gun, install the cover tape on the feeder as required, and then install the feeder on the feeder trolley.

Operation precautions: When changing the tray to load the material, first confirm the code and direction, and then load the material according to the direction of the loading table. Handle with care and wear anti-static gloves during operation.

Common problems and solutions

Improper feeder selection: Select a suitable feeder according to the specifications, shape and weight of the components to ensure compatibility and stability.

Suction nozzle is damaged or blocked: Regularly check whether the suction nozzle is damaged or blocked, and replace or clean the suction nozzle in time.

Transmission spacing adjustment: Adjust the transmission spacing according to the type and spacing of the belt feeder to ensure normal transmission.

Through the above introduction and maintenance methods, the normal operation and efficient use of the ASM placement machine label feeder can be ensured