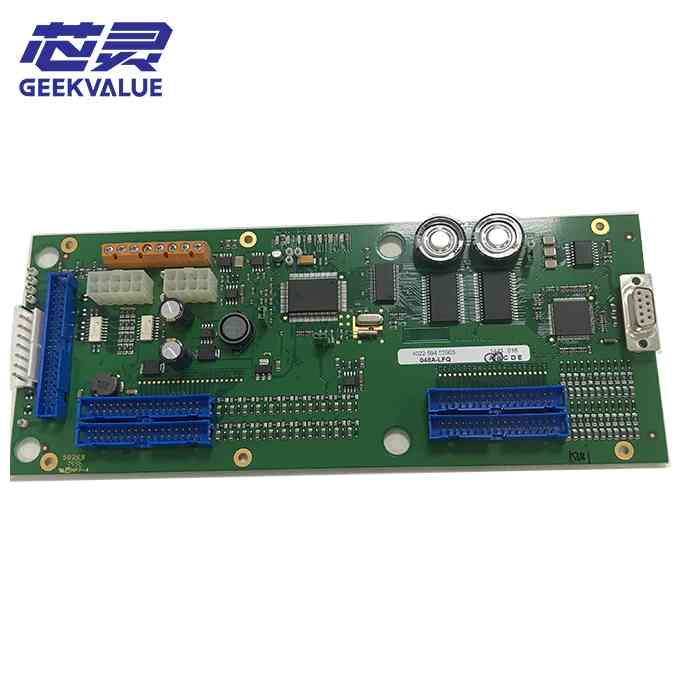

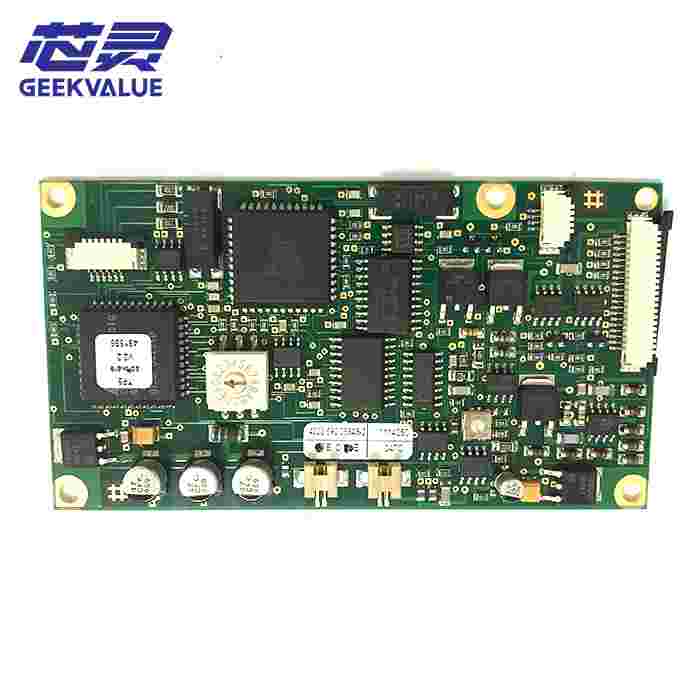

The core functions of Philips placement machine control board mainly include the following aspects:

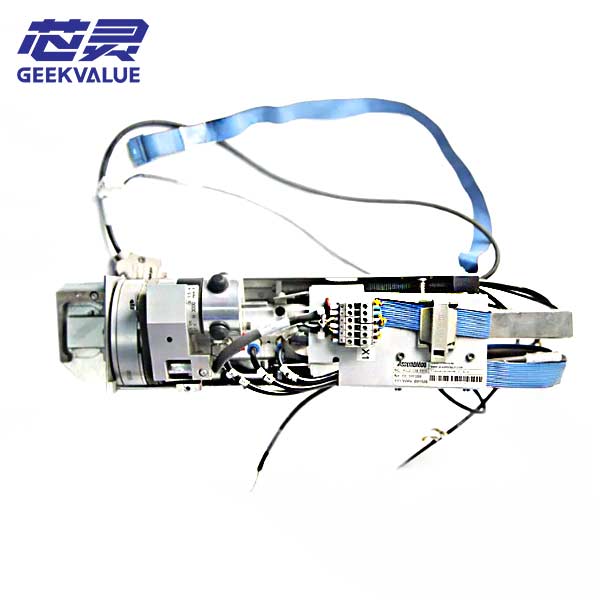

Automated control: The control board is responsible for automatically controlling various operations of the placement machine, including steps such as loading, component identification, placement and quality inspection. Through precise automation control, the placement machine can efficiently handle the placement of various small electronic components, significantly improving production efficiency.

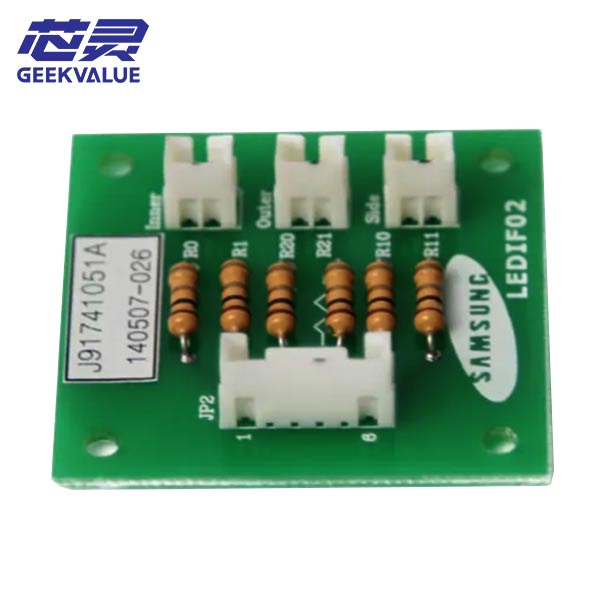

Data processing: The control board has a built-in advanced processing unit that can process a large amount of data, including component information, position data, etc., to ensure the accuracy and efficiency of placement. By integrating the visual recognition system and the intelligent material management system, the placement machine can automatically identify components and accurately place them at designated locations, and at the same time conduct quality inspection to ensure placement quality.

System integration: Modern chip placement machine control boards usually integrate a variety of functions, such as online quality inspection, intelligent material management, etc. The application of these functions further improves production efficiency and product quality. With the development of the Internet of Things and smart manufacturing technology, placement machine control boards are expected to be more closely integrated with other manufacturing equipment to jointly build an intelligent manufacturing system.

The role of Philips placement machine control boards in the electronics manufacturing industry:

Improve production efficiency: Through automation and intelligent control, Philips placement machines can complete placement work quickly and accurately, significantly improving production efficiency. In surface mount technology (SMT), the placement machine is one of the indispensable equipments that can efficiently handle the placement of a large number of small electronic components.

Ensure product quality: The built-in quality detection function of the control board ensures the accuracy of placement, reduces errors caused by human operations, and improves the overall quality of the product. By integrating the visual recognition system and online quality inspection, Philips placement machines can monitor and adjust in real time during the production process to ensure the placement quality of each component.

Promote technological innovation: With the development of the Internet of Things and intelligent manufacturing technology, the application scope of Philips placement machine control boards continues to expand, and it can be closely integrated with other manufacturing equipment to jointly build an intelligent manufacturing system. This integration not only improves production efficiency, but also promotes continued innovation and development in the electronics manufacturing industry