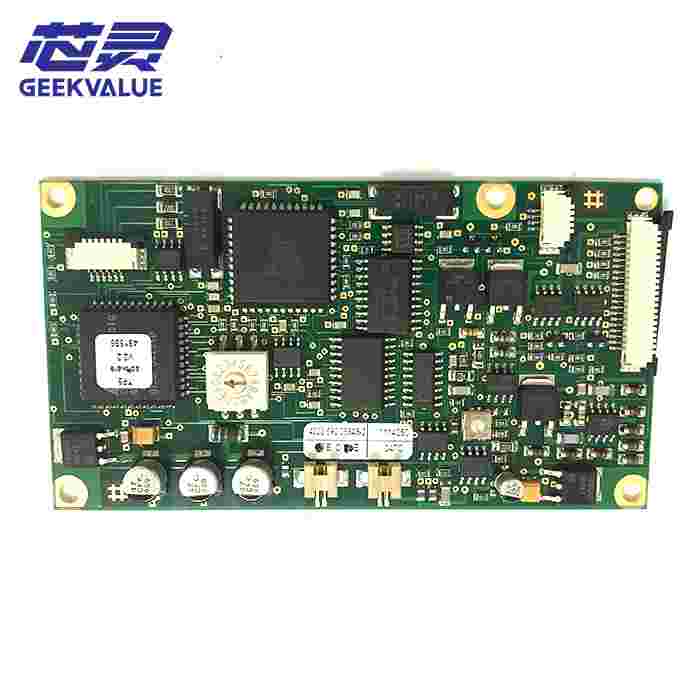

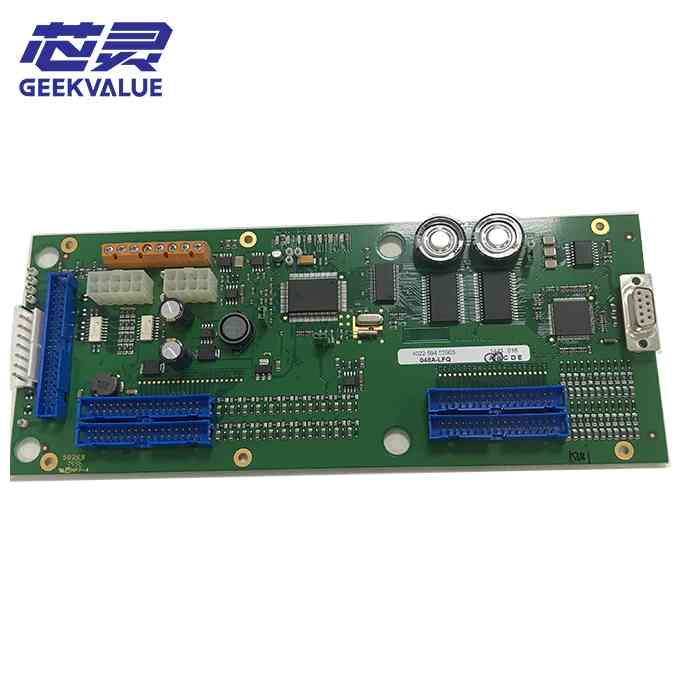

Sony SMT board is an important part of Sony SMT, which is mainly responsible for controlling various operations and functions of SMT. The following are the main functions and features of Sony SMT board:

Main functions of the board

Control the placement head: The placement head is a very important part of the SMT machine, and its main functions include sucking, correcting and blowing. Through the principle of vacuum adsorption, the Cassette or BULK components are adsorbed to the suction nozzle, and then the center offset and deflection of the components are identified by the parts camera, and corrected by the XY axis and RN axis, and finally the components are mounted on the PCB board.

Motion control: The board is responsible for controlling the movement of the placement head, including plane movement (XY axis), vertical movement (H axis), revolution movement (RT axis) and rotation movement (RN axis) to ensure the precise movement and positioning of the placement head.

Feeder management: The board is also responsible for managing the operation of the feeder, including loading, unloading and replacing the feeder to ensure the supply of materials in the production process. Application scenarios and actual effects of boards

Sony SMT boards are widely used in various electronic component placement production lines, and can meet the needs of high precision and high production capacity. Its high efficiency and versatility make it an important position in modern electronic manufacturing, especially in scenarios that require high-speed and high-precision production.

In summary, Sony SMT boards provide strong technical support for modern electronic manufacturing through its precise motion control, efficient management functions and a wide range of application scenarios.