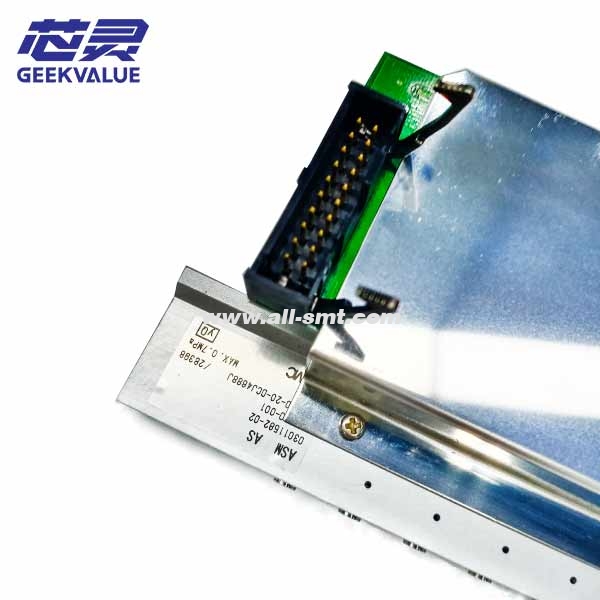

The main function of the ASM placement machine feeder unlocking device is to ensure the safe operation of the feeder during replacement or maintenance, and to prevent accidents during operation.

Working principle of the unlocking device

The unlocking device is usually controlled mechanically or electronically to ensure that the feeder cannot be removed or replaced in an unlocked state. Specifically, when the feeder needs to be replaced, the operator needs to follow specific steps to unlock the device first, and then safely replace the feeder. This design can effectively prevent the feeder from suddenly falling off or being damaged during operation, ensuring production safety.

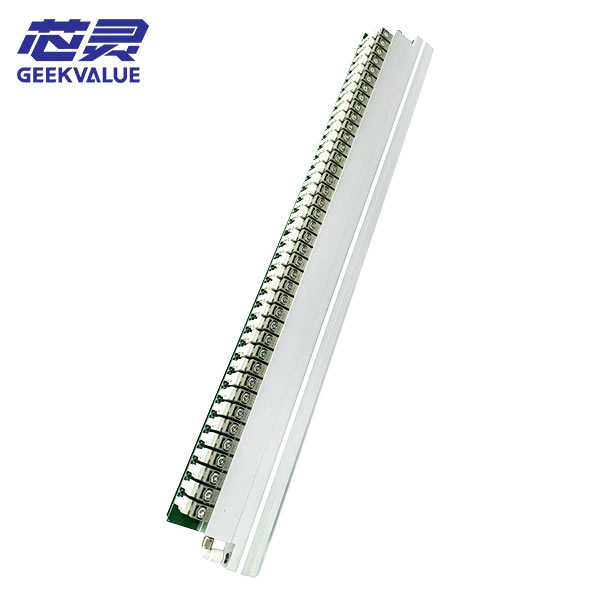

How to use the unlocking device Check the processed material: Make sure that the material is correct and suitable for the current operation. Determine the feeder type: Select a suitable tape feeder according to the width of the tape. Check the feeder: After confirming that there is no abnormality in the feeder, open the feeder, pass the tape through the feeder muzzle, and install the cover tape on the feeder as required. Install the feeder: Install the feeder on the feeder trolley, pay attention to the vertical placement of the feeder and the feeder table, handle it with care, and wear anti-static gloves. Feeding: When changing the tray to feed, first confirm the code and direction, and then feed according to the direction of the feeding table.

Maintenance and maintenance suggestions for the unlocking device

Handle with care: Handle the feeder with care during operation to avoid damage to the unlocking device.

Wear anti-static gloves: Wear anti-static gloves during operation to prevent static electricity from damaging the equipment.

Regular inspection: Regularly check the working status of the unlocking device to ensure that it is in good working condition.

Follow the operating procedures: Strictly follow the operating procedures to avoid equipment damage caused by misoperation