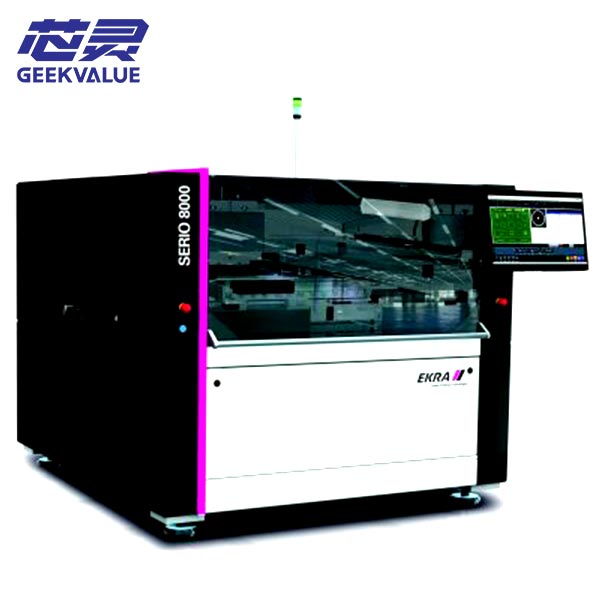

Fully automatic steel mesh inspection machine is an efficient and automated testing equipment, mainly used for quality monitoring of steel wire mesh. It combines computer technology and high-precision sensors, can quickly and accurately detect various parameters of steel wire mesh, and significantly improve production efficiency and product quality.

Main features High degree of automation : The detection process of the fully automatic steel mesh inspection machine is fully automated, without manual intervention, which greatly improves work efficiency and production benefits. The equipment can complete the automatic detection of steel wire mesh in a short time, avoiding the deficiency of traditional manual inspection requiring a lot of manpower and time . High-precision sensor : Using high-precision sensors for detection, it can detect the diameter and strength of each steel wire, ensuring that every inch of steel wire can pass the quality inspection smoothly, avoiding the misjudgment that is easy to occur in traditional manual detection . Multiple detection functions : In addition to the basic steel wire diameter and strength detection, it can also detect multiple parameters such as the surface quality of the steel wire, the aspect ratio of the finished product, and the number of the steel wire, to help carry out all-round detection . High efficiency and energy saving: The equipment can quickly complete the inspection of a large number of steel meshes, and can automatically shut down and enter low power consumption mode to save energy and electricity.

Application scenarios

Fully automatic steel mesh inspection machines are widely used in the field of electronic product manufacturing, especially in SMT (surface mount technology), to detect the quality of steel mesh printed with solder paste. As modern electronic products tend to be light, thin, short and small, the requirements for manufacturing technology are becoming increasingly stringent, and the inspection of steel mesh quality is particularly important. Fully automatic steel mesh inspection machines can effectively solve the problems of errors and instability in manual inspection and ensure production quality.

Operation and maintenance

The operation and maintenance of fully automatic steel mesh inspection machines are relatively simple. Operators must undergo special training and be verified to be qualified before they can operate. Daily inspections are required before the equipment is operated to ensure that there will be no adverse effects on surrounding people and objects. When the equipment is running, do not open the front cover of the equipment to avoid accidents. During the operation of the equipment, a certain amount of space needs to be maintained for maintenance and internal heat discharge.

In summary, the fully automatic steel mesh inspection machine plays an important role in modern manufacturing with its high efficiency, automation and high precision, and significantly improves production efficiency and product quality.