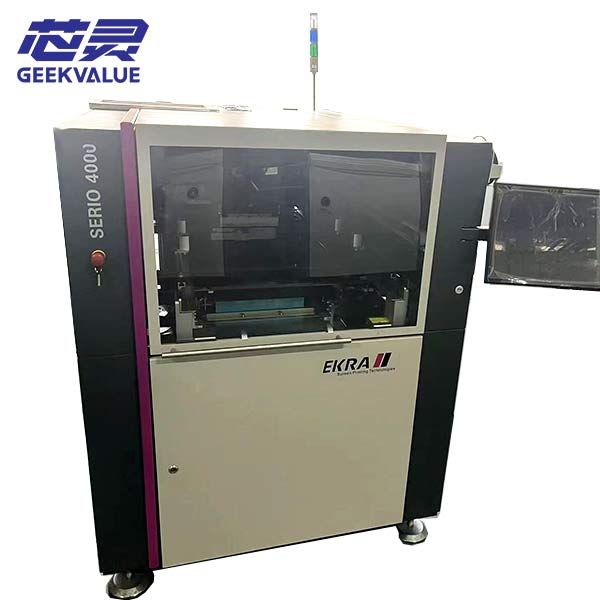

The features of Ekra SERIO 4000 B2B mainly include the following aspects:

Small footprint and efficient: With its small footprint and smart design, the SERIO 4000 B2B printing system can be used in production in a very space-saving manner, maximizing the use of space. Additionally, the two printing systems can be installed back-to-back and work independently, ensuring not only a flexible and space-saving design but also significantly improved throughput rates.

Dynamic scalability: The SERIO 4000 printing press is based on more than 40 years of printing press design and application experience. After many revisions and upgrades, it meets the technical requirements of high-end manufacturing, as well as the latest requirements of Industry 4.0. It is dynamically scalable and provides users with a variety of professional options or functional modules that can be flexibly adjusted according to individual needs.

High printing precision and productivity: SERIO 4000 B2B inherits the high printing precision, high automation and friendly human-computer interaction interface of SERIO 4000.1. In addition, it also optimized the machine structure and upgraded the control module, achieving improved printing accuracy (increased by 20%), increased theoretical production capacity (18%) and extended independent production time (33%).

Wide range of applications: SERIO 4000 B2B is suitable for high-end automotive electronics and semiconductor industries, and can meet the growing production capacity needs of these industries and the need to control the cost per unit area of the workshop