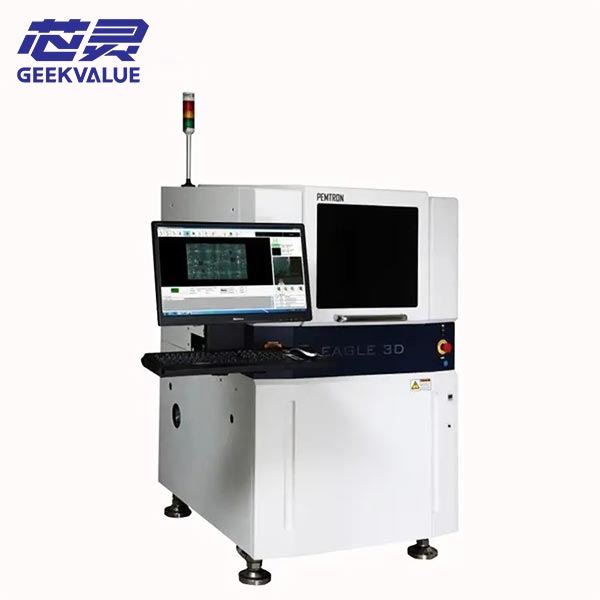

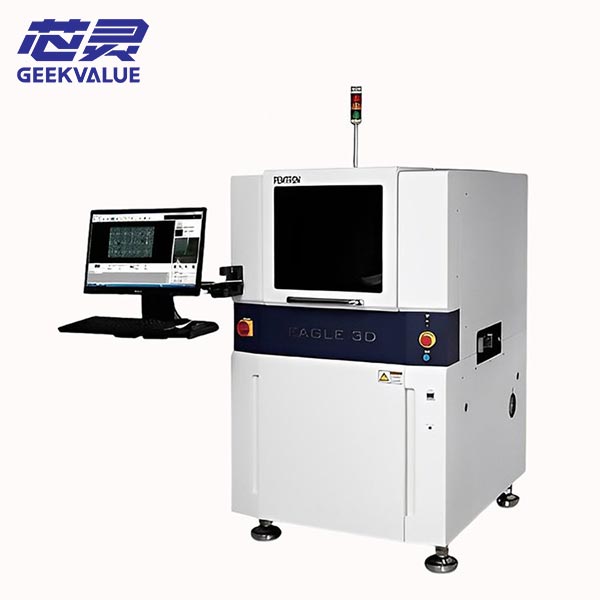

The functions of Bentron SPI 7700E mainly include the following aspects:

Dual 3D light source: Combining 2D and 3D technology, effectively eliminating the influence of shadows, providing high-quality 3D images, and ensuring high precision and high speed of testing.

64-bit Win 7 system: Provides high-speed and high-stability computer system configuration to meet the needs of complex product design.

True color 3D image: Through the patented Color XY technology, it can distinguish copper foil, accurately find the zero reference plane, and display true color 3D images rotated at any angle, making it easier for users to see clear solder paste images.

Board bending compensation: Through a larger zero reference plane search range, it provides more accurate height calculation and better repeatability data.

Foreign matter detection: Using the Color XY algorithm, it can distinguish foreign matter and PCB substrates, and is suitable for PCBs of various colors.

Powerful SPC function: Real-time monitoring and analysis of bad data in the production process, providing detailed SPC reports, and supporting multiple formats of output.

These features make the Bentron SPI 7700E perform well in the field of SMT patch. It is widely used in automotive electronics, 3C manufacturing, military and aerospace, and is favored by SMT patch manufacturers.