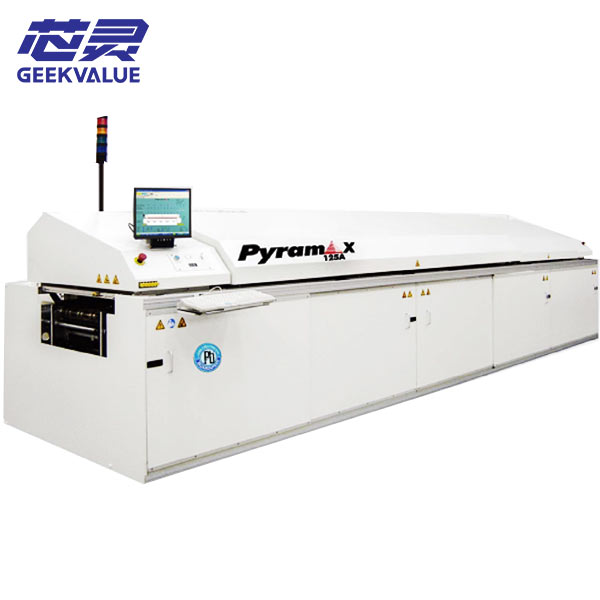

BTU Pyramax-150A-z12 Reflow Oven is a reflow oven designed for high-volume, high-throughput production environments launched by BTU International. The equipment debuted at the 2009 Shanghai NEPCON exhibition and has attracted widespread attention for its advanced technology and excellent performance.

Btu reflow oven pyramax -150a-z12 Technical specifications and performance parameters

Number of temperature control zones: 12 temperature control zones, which greatly improves the process control capability of lead-free processes.

Maximum temperature: 350°C, suitable for lead-free processing.

Heating method: Adopt hot air forced impact convection circulation to ensure system stability and temperature uniformity.

Temperature control accuracy: Controlled by PID calculation method, high temperature control accuracy, temperature uniformity ±2°C23.

Advanced technology and design features

Closed-loop convection control: BTU's unique closed-loop convection control function can accurately control heating and cooling, provide constant heat transfer, and ensure process consistency and flexibility.

High-efficiency heating: Adopting side-to-side gas circulation to avoid temperature and atmosphere interference in each zone, the heating efficiency is high and it is suitable for larger and heavier PCB boards.

Energy-saving design: During stable operation, the heating power only needs 20-30%, which significantly reduces energy consumption3.

High degree of automation: Equipped with Wincon control system, it has powerful functions and a simple and easy-to-operate user interface.

Application fields and market performance

The BTU Pyramax-150A-z12 reflow oven enjoys a high reputation in the PCB assembly and semiconductor packaging industries and is considered one of the highest standards in the global industry. Its efficient convection heating and precise temperature control make it perform well in mass production environments and meet the needs of high-capacity heat treatment.

In summary, the BTU Pyramax-150A-z12 reflow oven has become an ideal thermal processing equipment in mass production environments with its advanced technology, efficient design and excellent performance.