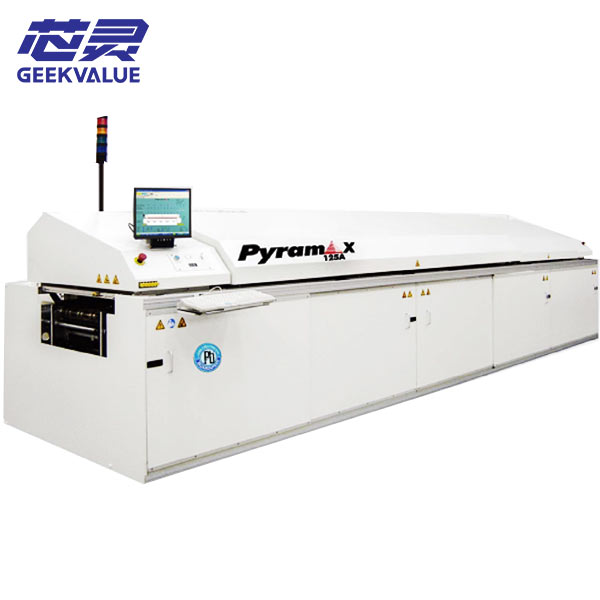

BTU Pyramax-125A reflow oven is a high-performance reflow soldering equipment, widely used in SMT reflow soldering, semiconductor packaging and LED packaging and other fields. The following is a detailed introduction of the equipment:

Technical parameters and performance characteristics

Maximum temperature: 350°C

Number of heating zones: 10 heating zones, divided into top and bottom heaters

Temperature control: Adopt PID calculation method, high temperature control accuracy and good temperature uniformity

Heating efficiency: Adopt hot air forced convection technology, high heating efficiency, suitable for larger and heavier PCB boards

Gas circulation: Side-to-side gas circulation to avoid interference between temperature and atmosphere in each zone

Temperature control thermocouple: The temperature control thermocouple and overheat protection thermocouple are close to the PCB board, and the displayed temperature is close to the actual temperature

Construction Structural design and use effect

Structural design: The upper and lower heaters of each zone adopt an independent structure, which consists of a three-phase motor, a fan, an open heating wire, a temperature control thermocouple, an overheat protection thermocouple and a gas distribution system. The system has a fast temperature response, uniform temperature and good reproducibility

Stability: The hot air forced convection impact heat conduction technology is adopted, the system has high stability, and the movement of small-sized devices is avoided

Easy maintenance: The equipment is reasonably designed, and the chain and track transmission design have a large turning angle at both ends of the furnace, which greatly reduces the chance of chain jamming, and the chain has an automatic lubrication function

Application field and user evaluation

BTU Pyramax series reflow ovens are known as the highest industry standard in the world in PCB assembly and semiconductor packaging industries. Its unique closed-loop convection control system maximizes the flexibility of process control and ensures the consistency of process curves of each furnace between different production lines. In addition, the Pyramax series reflow ovens excel in high-capacity heat treatment, are suitable for lead-free processes, and have excellent temperature uniformity and super curve control functions.

User evaluation and market performance

BTU Pyramax series reflow ovens have performed well in the global market and are widely used in the electronics industry. Its efficient convection heating technology and precise temperature control enable it to perform well in the SMT process and have been widely recognized and used.