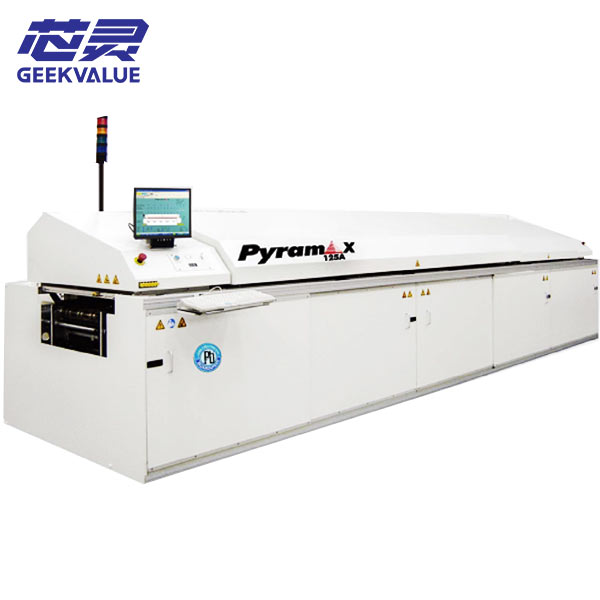

BTU Pyramax-100 Reflow Oven is a reflow oven produced by BTU, which is widely used in PCB assembly and semiconductor packaging. The following is a detailed introduction of the equipment:

Product Features

High-capacity thermal treatment: In the PCB assembly and semiconductor packaging industries, BTU's Pyramax reflow oven is known as the highest standard in the global industry, providing optimized lead-free processes to maximize productivity and efficiency.

Closed-loop convection control: BTU's unique closed-loop convection control system can accurately control the heating and cooling process, reduce nitrogen consumption, and reduce production costs.

Temperature uniformity: The Pyramax reflow oven adopts an edge-to-edge convection circulation method to ensure temperature uniformity and ensure the consistency of process curves between different production lines.

Efficient convection heating: Adopting forced impact convection technology, it has high heating efficiency, fast temperature control and good reproducibility.

User-friendly: The WINCON system has powerful functions and a simple and easy-to-operate user interface, suitable for various operating needs.

Technical parameters

Maximum temperature: 350°C, optional 450°C

Temperature control accuracy: 0.1°C

Heating method: electric heating wire

Number of heating zones: 10 heating zones

Heating power: maximum 3000W

Heating speed: Reach maximum temperature within 5 minutes

Application areas

Pyramax reflow oven is suitable for printed circuit board assembly, semiconductor packaging and LED assembly, especially in lead-free process.

User evaluation and industry status

BTU Pyramax reflow oven is widely recognized worldwide, and its high capacity, high efficiency and precise control make it a leading product in the industry. Many large electronic manufacturing companies such as Motorola, Intel, etc. are using BTU's reflow oven, proving its excellent performance and reliability.

In summary, BTU Pyramax-100 reflow oven has become an excellent choice in the field of PCB assembly and semiconductor packaging with its high capacity, precise control and user-friendly design.