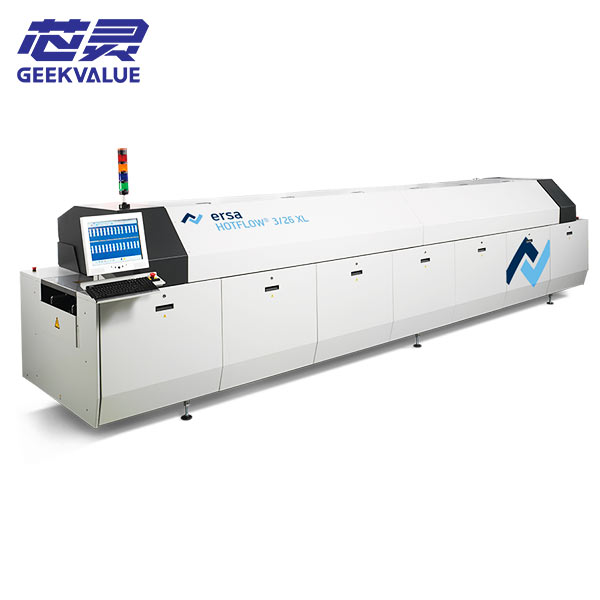

ERSA Hotflow-3/26 is a reflow oven produced by ERSA, designed for lead-free applications and high-volume production. The following is a detailed introduction to the product:

Features and Advantages

Powerful heat transfer and heat recovery capabilities: Hotflow-3/26 is equipped with a multi-point nozzle and a long heating zone, which is suitable for soldering large heat capacity circuit boards. This design can effectively increase the efficiency of heat conduction and improve the thermal compensation capability of the reflow oven.

Multiple cooling configurations: The reflow oven provides multiple cooling solutions such as air cooling, ordinary water cooling, enhanced water cooling and super water cooling, with a maximum cooling capacity of up to 10 degrees Celsius/second, to meet the cooling needs of different circuit boards and avoid misjudgment caused by high board temperature.

Multi-level flux management system: Supports multiple flux management methods, including water-cooled flux management, medical stone condensation + adsorption, specific temperature zone flux interception, etc., to facilitate equipment maintenance.

Full hot air system: The heating section adopts a multi-point nozzle full hot air system to effectively prevent small components from shifting and blowing away, and avoid temperature interference between different temperature zones.

Vibration-free design and stable track: The track is designed to be vibration-free throughout the entire process to ensure stability during the welding process, prevent disturbance of solder joints, and ensure welding quality.

Application scenarios

Hotflow-3/26 reflow oven is widely used in emerging industries such as 5G communications and new energy vehicles. With the development of these industries, the thickness, number of layers and heat capacity of PCBs continue to increase. Hotflow-3/26 has become an ideal choice for reflow soldering of large heat capacity circuit boards with its powerful heat transfer capabilities and multiple cooling configurations.